Some boundary conditions:

(1) Stage voltage equals charge voltage – 20-25 kV range would be most suitable to fit an easy-to-build flyback transformer type supply.

(2) Discharge energy should be at least 10 Joules, otherwise, there is not enough noise and the thing doesn’t look and feel dangerous enough (you might as well use a piezo fire lighter to make some sparks…)

(3) Charge time should be reasonable, not more than a few seconds.

With 16 0.1 µF capacitors, rated for 1.6 kV and operated at 1.5 kV (24 kV per stage), a design was established that uses 10 stages – about 220-230 kV peak voltage. This results in about 20 Joules of discharge energy.

It was also found that there is no need to make the stage charging resistors very large (some sources suggest multiple Megaohms, 1 M is just fine for most of the designs relevant in this context). A value of about 8 M was determined for the charge resistor – mostly because of the 0.5 mA current limit of the power supply – you can use a lower value, if you want to put more current into the Marx. But remember that a high-value charge resistor will also protect the rectifier cascade of you power supply, so you might not want to take too big risks.

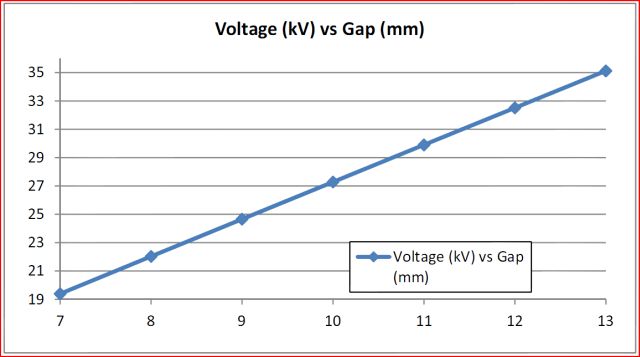

For the spark gap – these are the approximate voltage for a gap mm:

Accordingly, the gaps were adjusted to about 8.5 mm using a plastic gauge (to avoid scratching of the spheres).

Note that the stage carrier plates have cut-outs at the spark gaps! This is to avoid unwanted discharge, but also to ensure line-of-sight contact of the spark gaps, which ensures stable triggering (because of UV radiation, emitted from one gap, lowering the spark cap threshold voltage of the next).

Full view

(in the back, you can see an earlier experimental model, using Wima FKP-1 capacitors – however, this design added a lot of inductance, and the adjustment of the spark gaps was not thought out very well).