Quick initial assessment, these are some of the items that will need attention:

(1) Exterior. Need to fabricate instrument feet, re-paint the panels, handles are missing – either need to get spares, or fabricate replacement handles (can only be done back at the main workshop in Germany, lacking machine tools here).

(2) The ground leakage -need to check the power supply. Hope it is not the transformer or other critical part.

(3) Power cable. Absolutely non-standard! Uses a BENDIX connector, 3 pin, type PT02E8-3P-027.

Interestingly enough, found a suitable cable, especially made for the MSR-904, on xbay, Army surplus! PN: SC-D-627094-5FT NSN:5995-00-165-3806, the guy has more then 10 pieces – seems the Army was really worried to run out of cables for their MSR-904s.

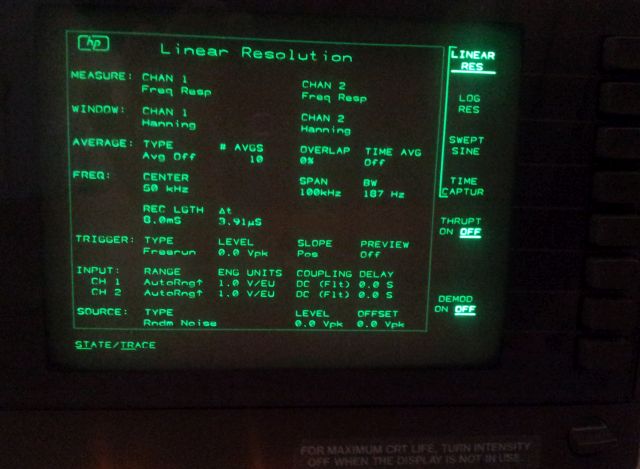

(4) The frequency display works but doesn’t show the right frequencies.

(5) The F2 adjustment (upper sweep stop frequency in F1-F2 mode) doesn’t work.

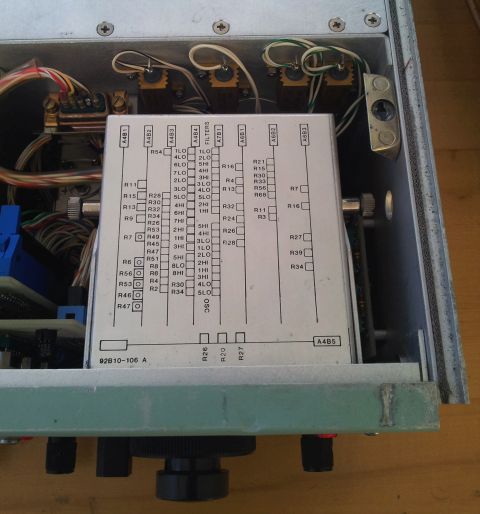

(6) Figuring out the major adjustment pots – this is all documentation I have:

(7) Figuring out the pinout of the “Monitor” port (intended to connect a storage scope, I might connect a digitizer), and of the “Remote” port – the remote control signals (TTL).

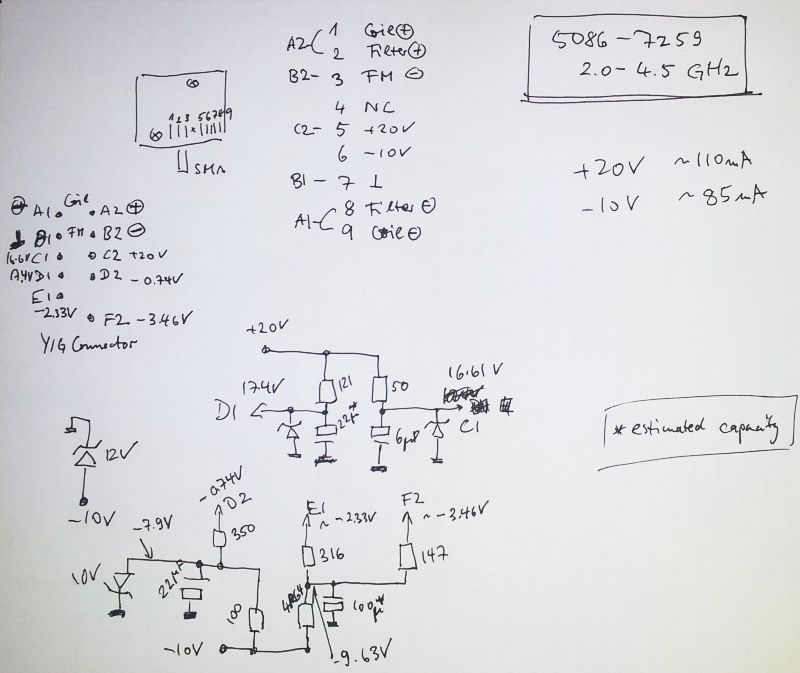

(8) Figuring out the external frequency control and phase lock voltage requirements.

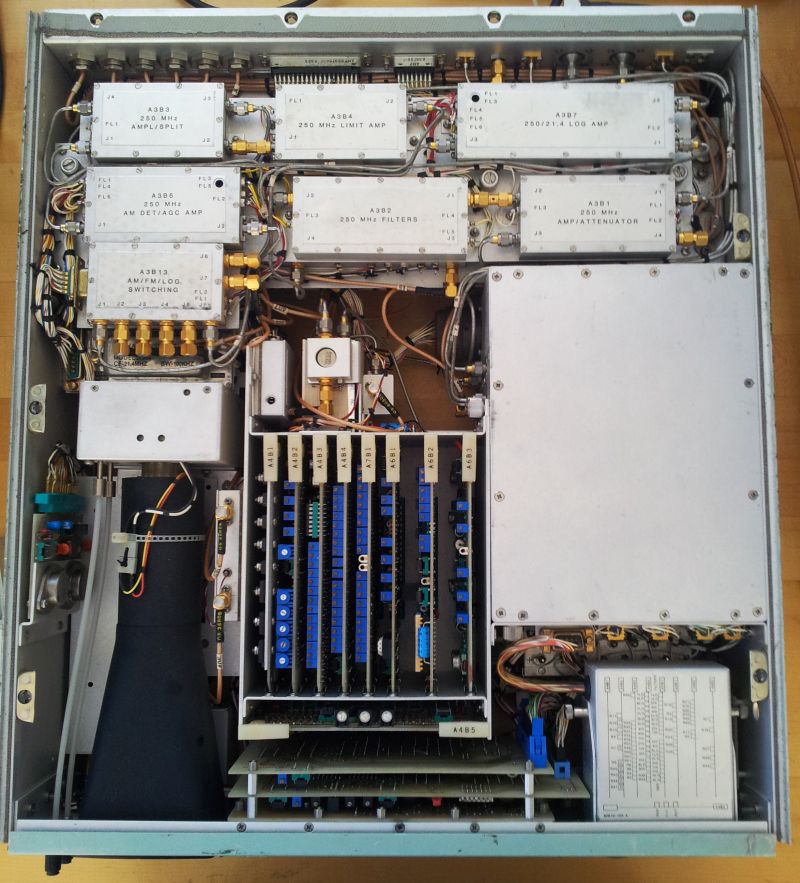

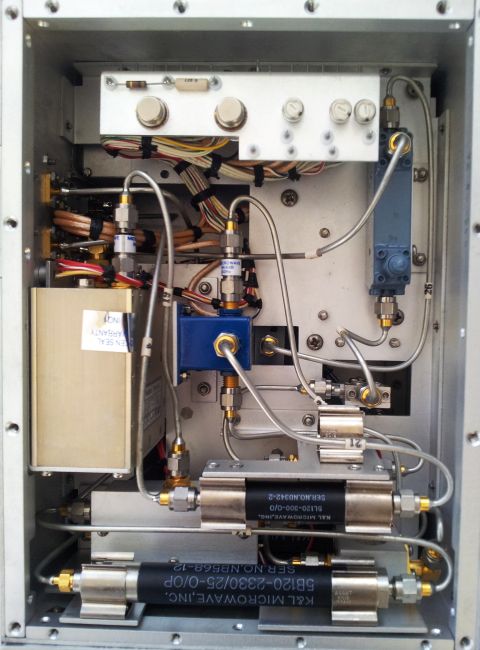

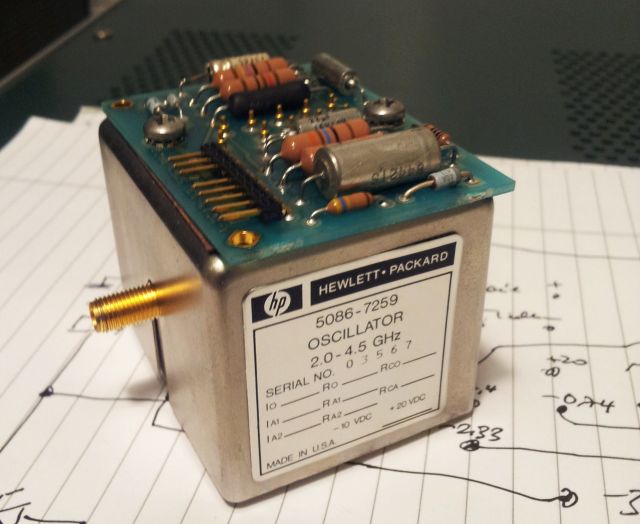

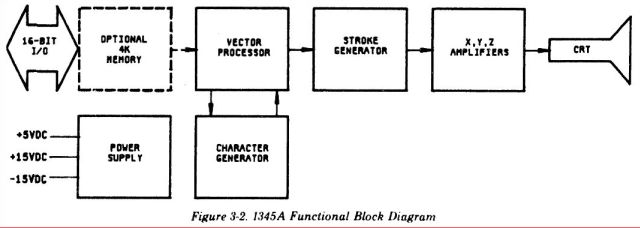

(9) Drafting a block diagram of the RF deck and IF chain, just to better understand the inner workings, and to see, which parts-components Micro-Tel used.

Now, on item (2).

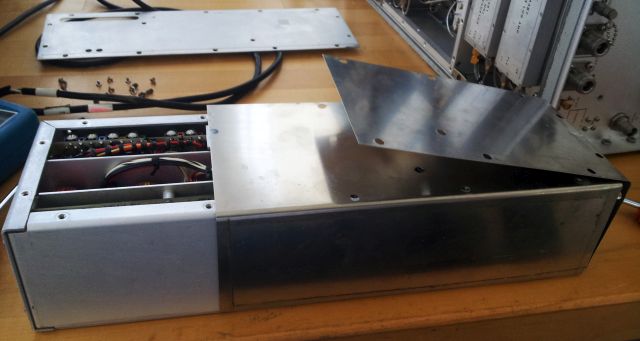

The power supply –

It’s held in place, and held together, by a cup full of screws. And, it has a layer of what is presumably Mu metal (high magnetically shielding sheet metal), to keep the 50-60 Hz in the transformer.

The filter, at the input, it is a sight in itself. Not sure how much it would cost to fabricate a custom aluminum case of this size, and to manually assembly it these days. Parts value alone, over 250 USD.

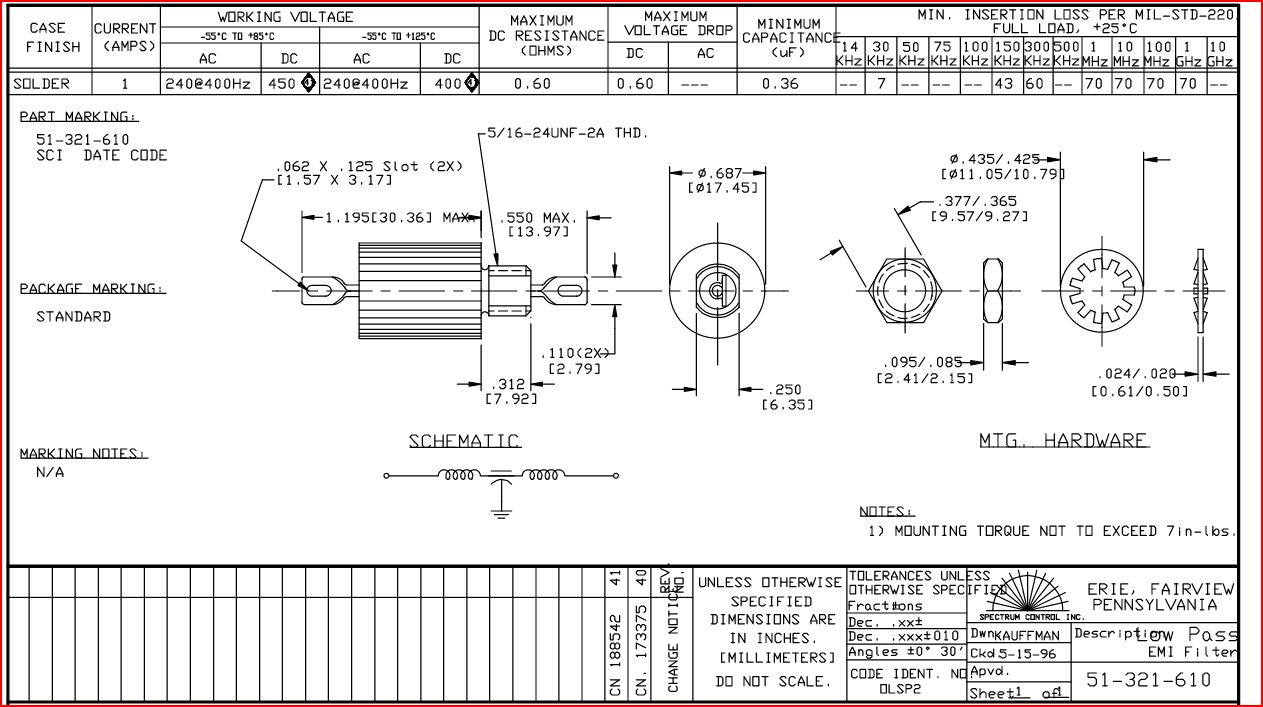

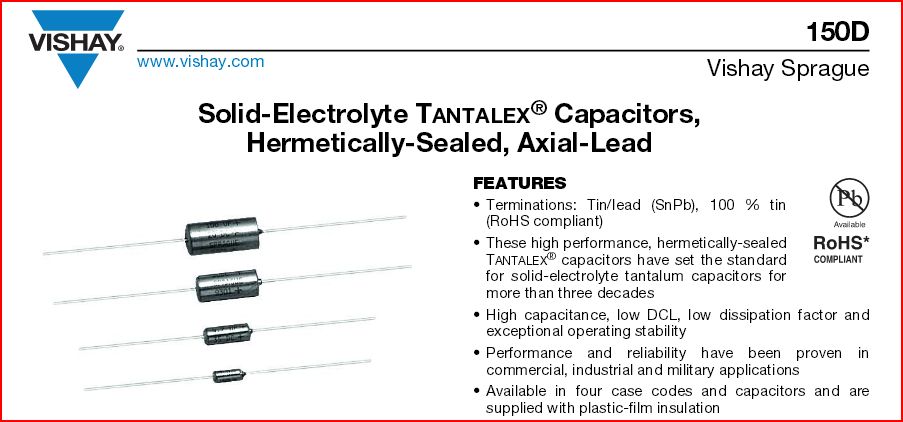

Well, and as it turns out, exactly these parts are leaky. SPI filters, 51-321-610, still available, after being around for 30+ years, at Mouser and elsewhere – 119.64 USD each, 18 pcs minimum order….

After a quick thought – I will give these parts a miss. With all the shielding, transformers and wires, we can do without hermetic feed-through filters – keeping in mind that also the bottom and top lid of the unit have ventillation holes.

So, filters removed, and wires re-connected… and, quite to my satisfaction, no ground leakage any more – not even a few microamps.

Before putting it back together – quick check of the power supply – all seems to be working fine now, and well adjusted.

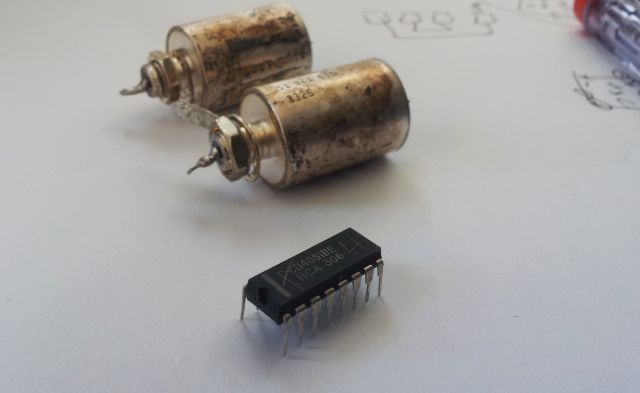

Item (4) – complicated. Took me quite some hours. The frequency meter is acutally a voltage meter, and this is controlled by the tuning voltage, and a complex digital circuit spread over some hard to reach board. After searching around – it’s just a defective CMOS multiplexer switch, setting the gain of one of the voltage conditioning stages (which are needed to handle the various bands). It’s and CD4051, standard item, no problem. Put in a good one, from another part of the circuit that is not criticial at this point, and ordered a few spares, just USD 1.75 for 3 pcs, including shipment, from Macau.

On item (5) – the sweep circuit is pretty similar to the Micro-Tel SG-811, and for the SG-811, I have the schematics around.

It uses a dual 10 turn potentiometer. 10k.

Helipot 6108 series, a type common to high-grade analog-control instruments. Seems that one of the stages (the stage that controls the sweep range) is defective – the hybrid resistance material used for the pot (these don’t use wire, because they are made for high resolution applications) is open at the “cold” end – sweeper is always at full scale.

As these are all fully sealed units, no way to repair – found an exact replacement second-hand, for a reasonable charge. For the time being- changed the wires: the F2 display (controlled by the second stage of the pot, which is still working), has been disabled, and the wires changed so that the acutal sweep range is now controllable – so I can do all adjustments, just don’t get a display for the F2 frequency.

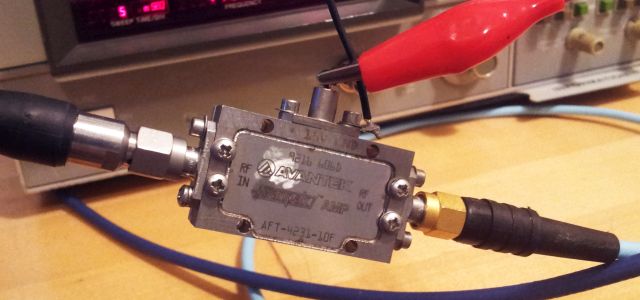

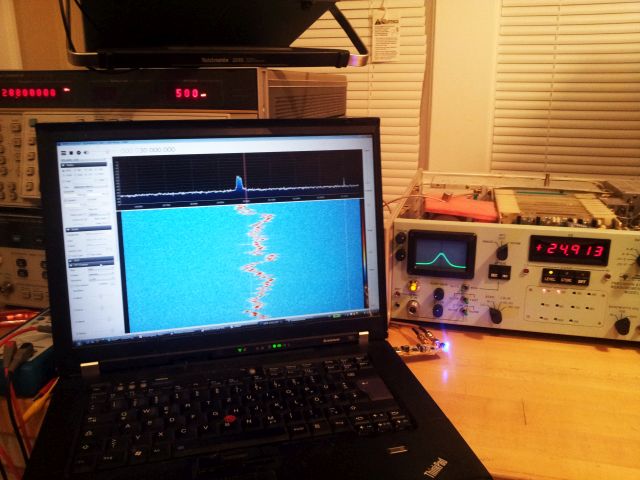

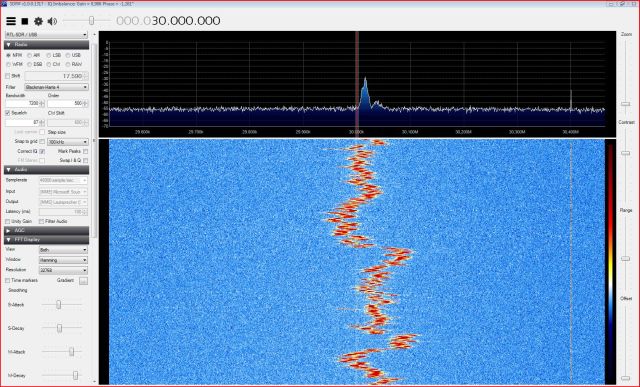

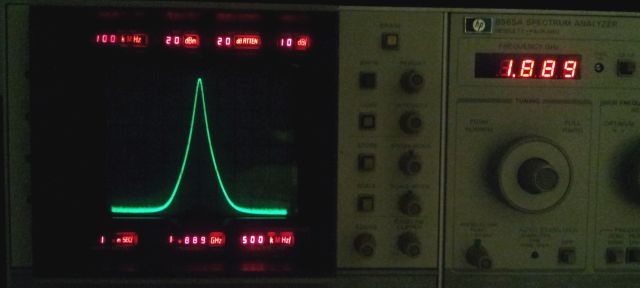

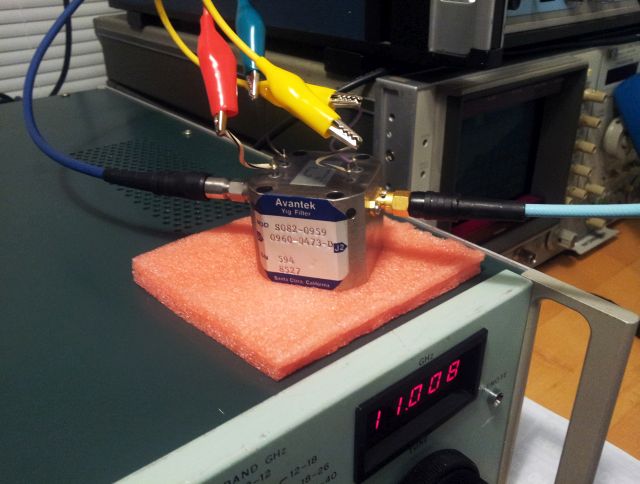

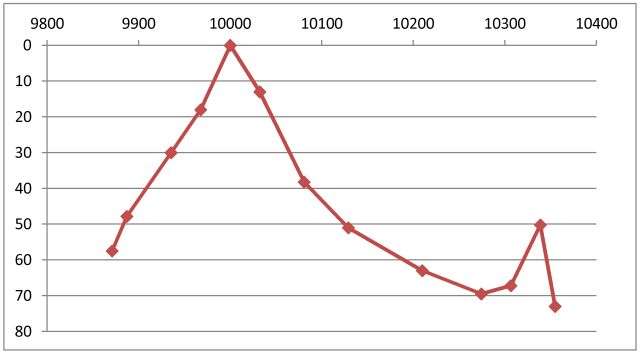

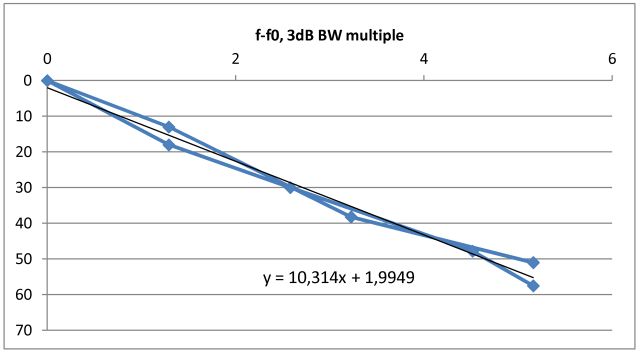

Well, and after all this, the unit is at least basically working, responding to controls, and not triggering any fuses. To move things further, setting it up with a few GHz range synthesizers, and an EIP 545A counter, for some first tests with RF.

To be continued…