With many parcels being shipped, and for some other projects including measuring the contents and consumption of LPG gas cyliners, other gas cylinders, chemical tanks etc, I always wanted a slim and stable balance, at low cost. Sure we can fabricate one from steel plates and load cells, at considerable cost. But why not try with a personal scales, and convert it to some usable tool. This scales from local LIDL supermarket comes for EUR 8.99 in the shop, 10 dollars.

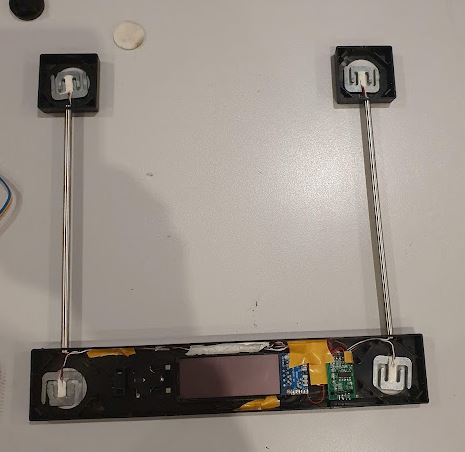

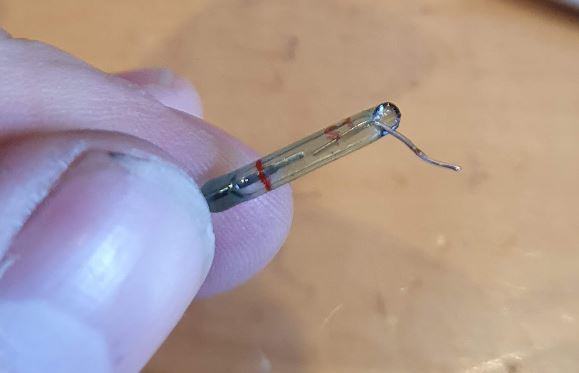

It is very slim and stable, basically a piece of hardened glass, with 4 load cells. There are 2 thin-walled stainless tubes to carry the wires to the main processor.

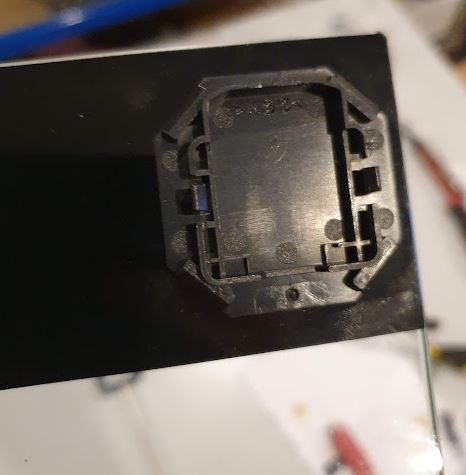

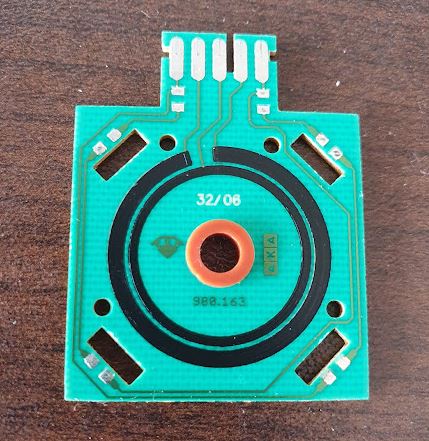

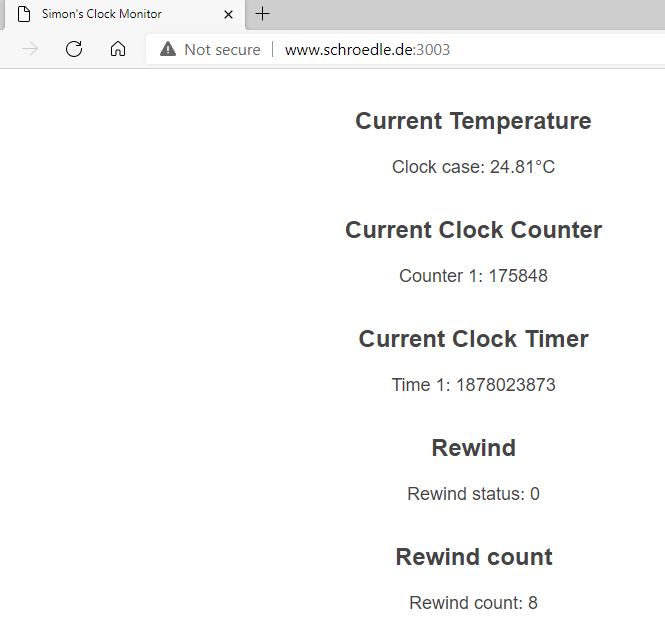

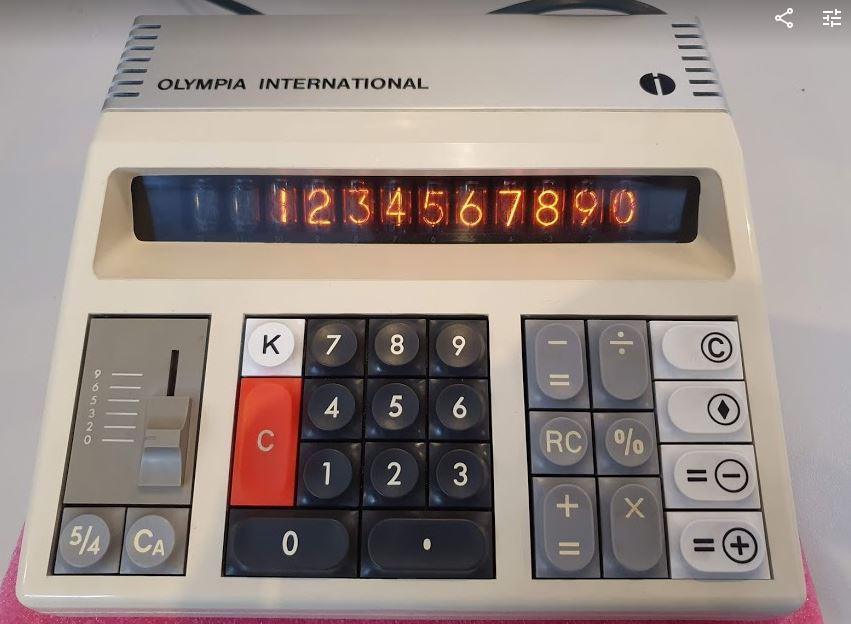

That’s the type, just for reference:

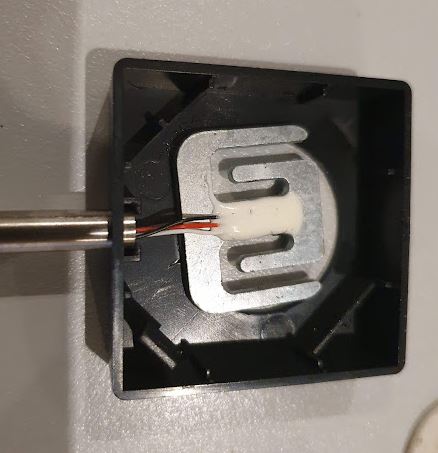

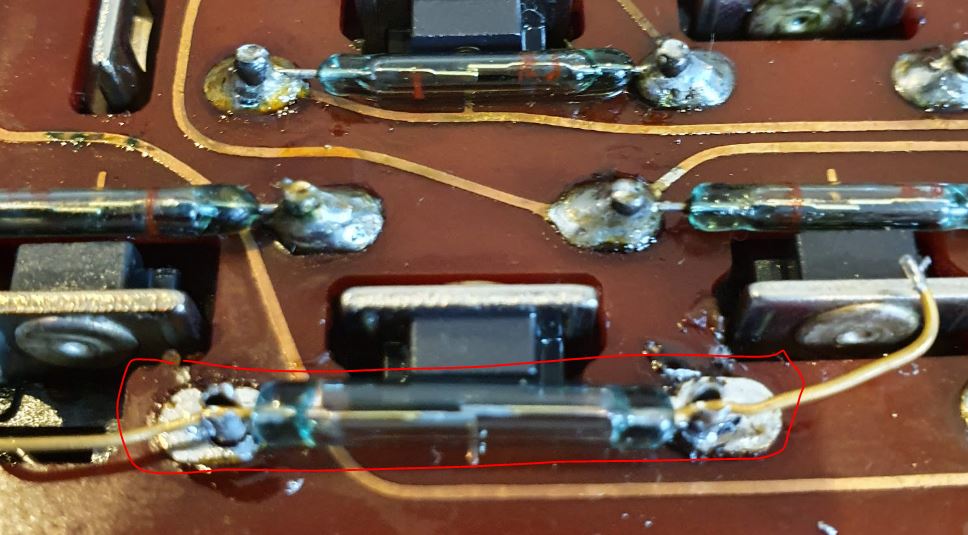

The load cells are the typical 3-wire elements (two load elements inside, red is the center).

The main disadvantage of these balances is (in addition to the absence of an interface) the absence of a continuous reading, in contrast to a good old analog balance it only shows one weight once, when you step on it. For various uses, I rather need a balance that continuously shows the weight, and can transfer it to a host for data analysis.

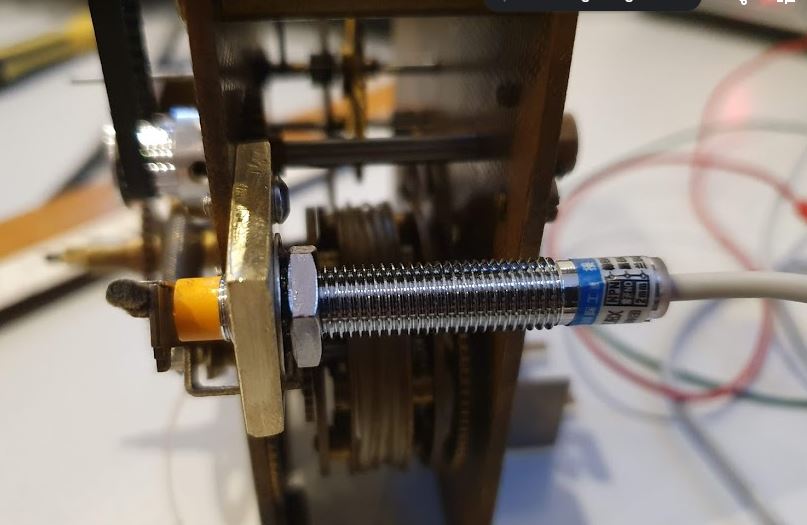

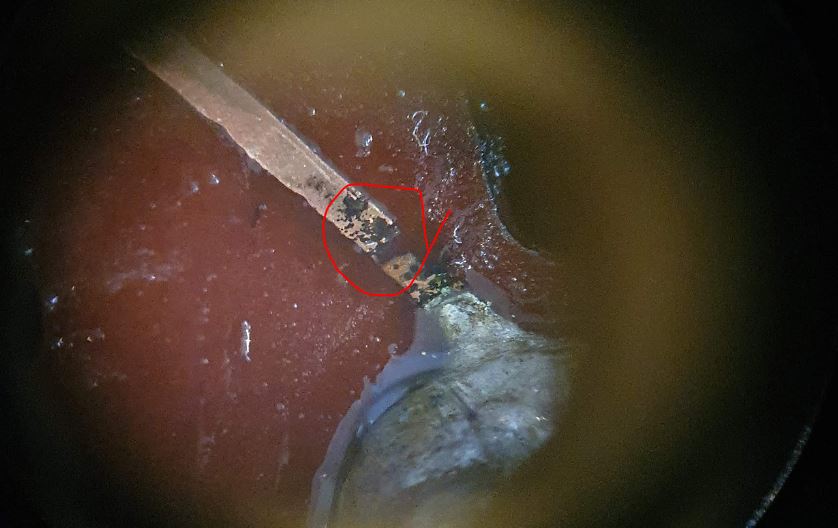

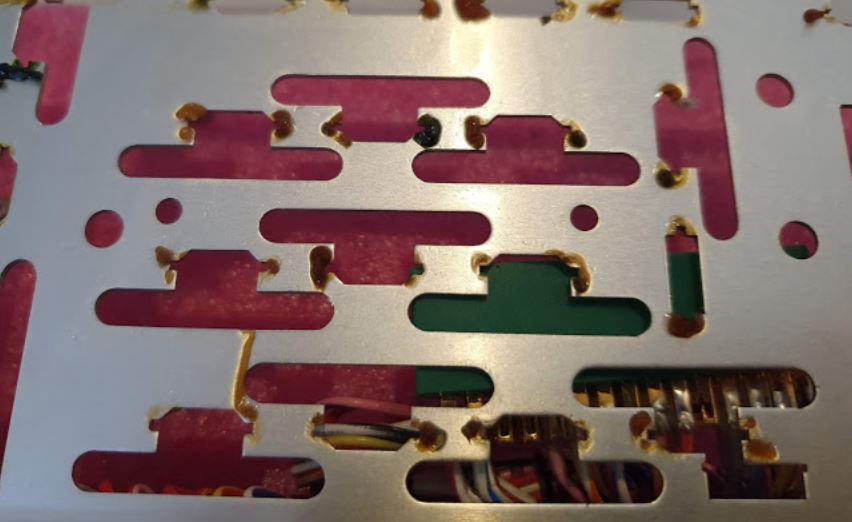

The load cells rest on certain plastic parts that are glued to the glass plate.

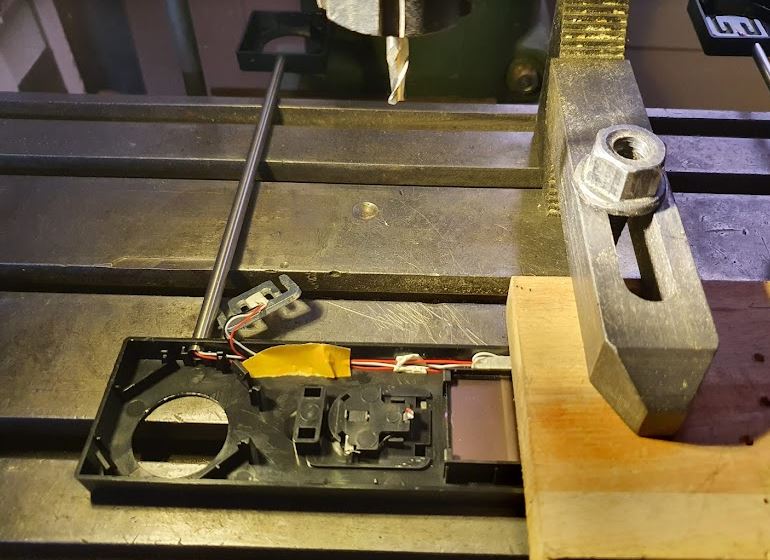

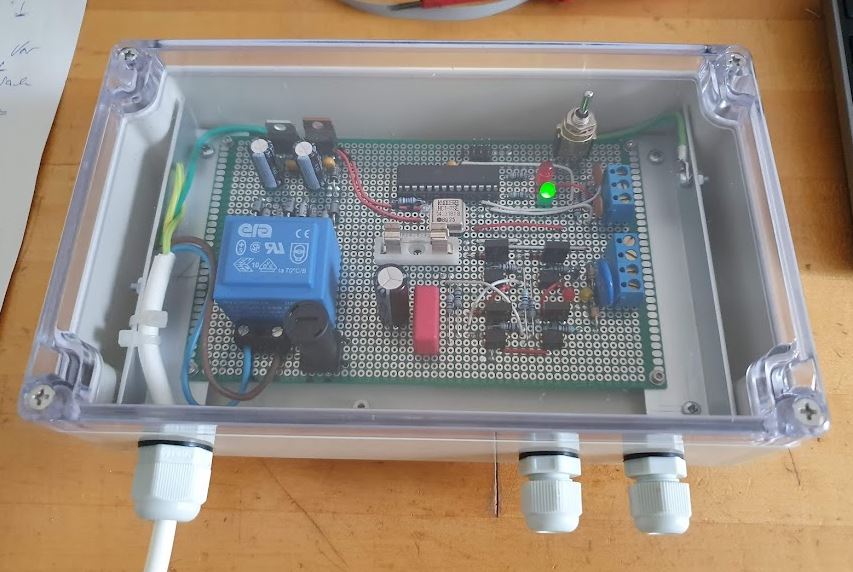

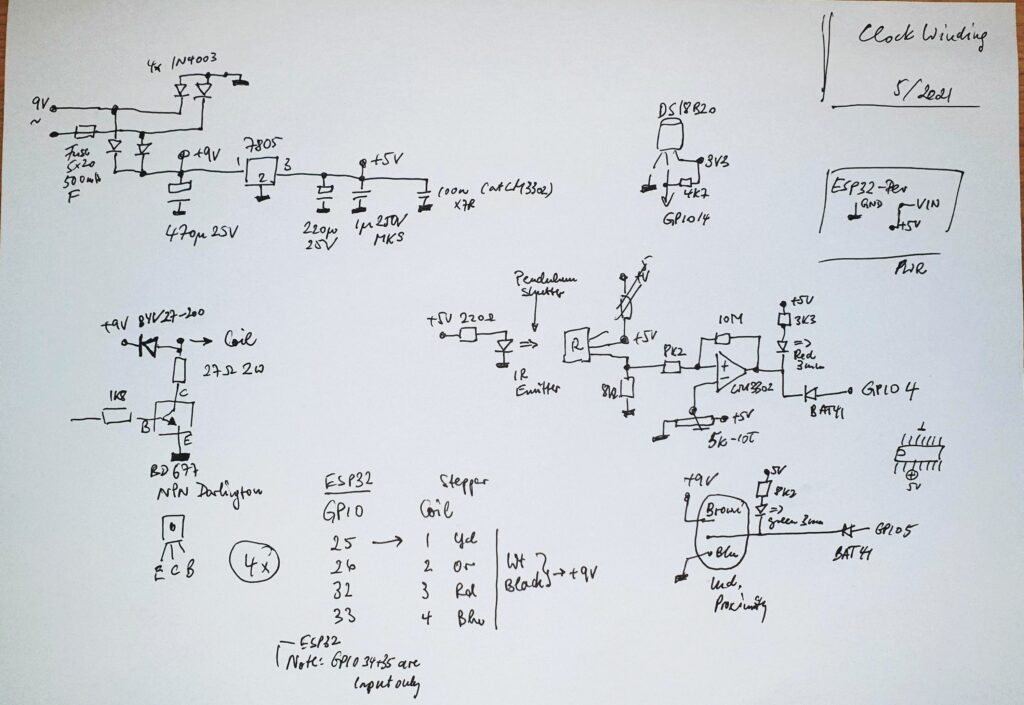

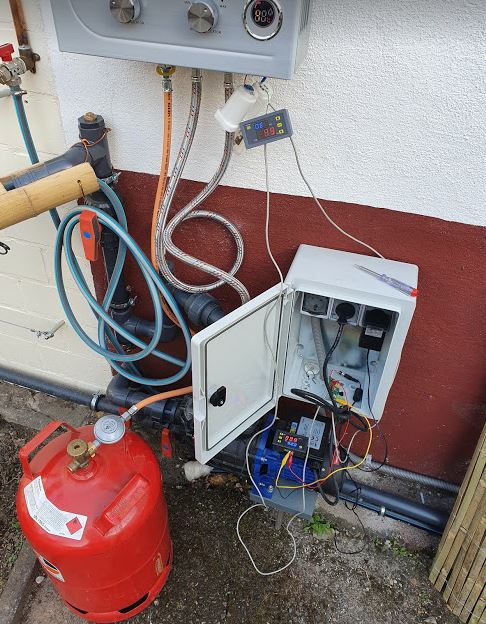

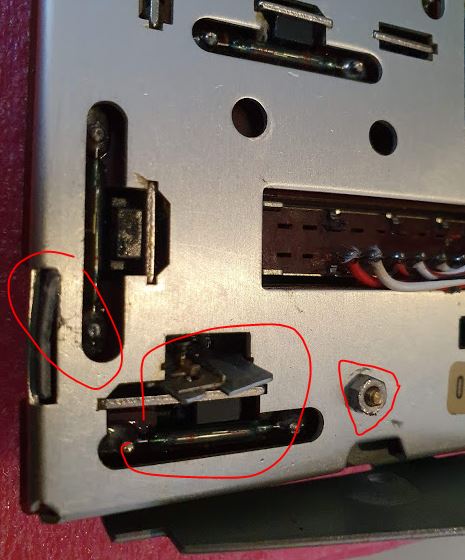

We need to cut a little modification on the milling machine, to make space for a small AVR controller board, and the USB (micro-USB) plug. There is no need to batteries any more, it will all be powered by USB.

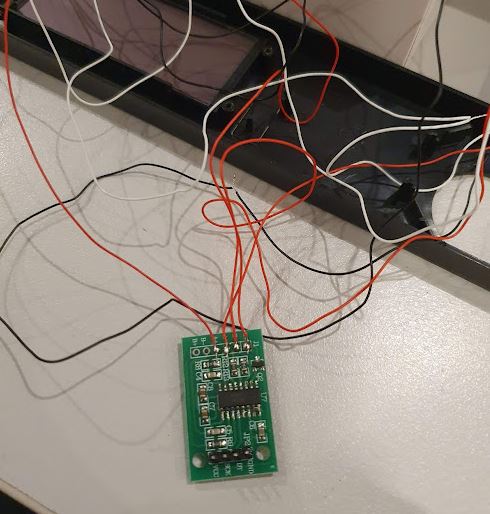

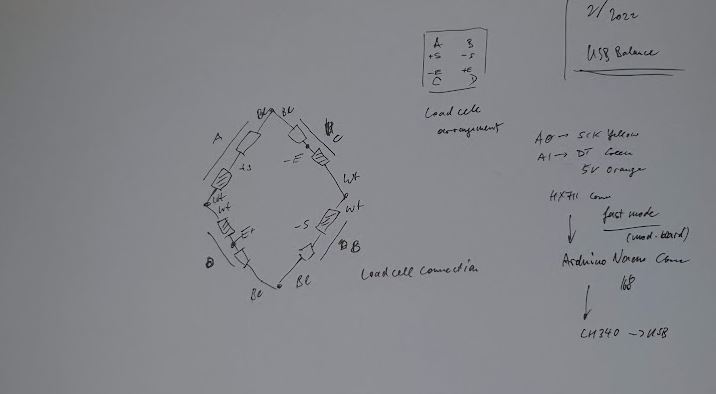

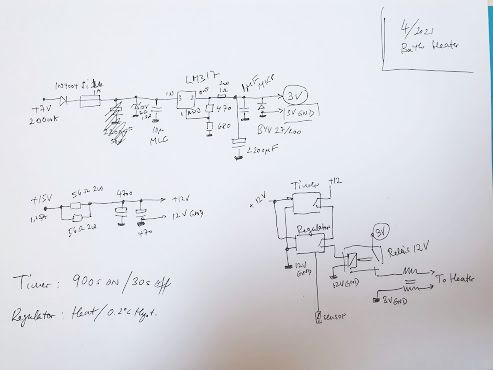

For the load cell interface, the 4 load cells need to be wired up in a bridge (not important in which order of the load cells, but always white-while black-black, and alternating red wired for drive and signal inputs.

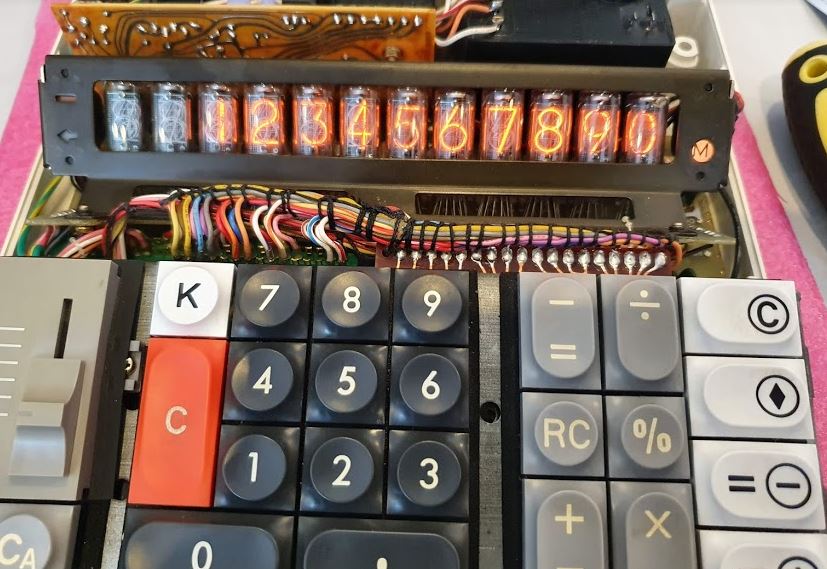

So we use a very common HX711 driver, it seems to work well with these load cells. I still had a board with higher data output rate (can be changed by floating a pin on the HX711), but you may select the data rate as you like. The HX711 is continuously active, and sending data to the host though a USB serial chip, CH340.

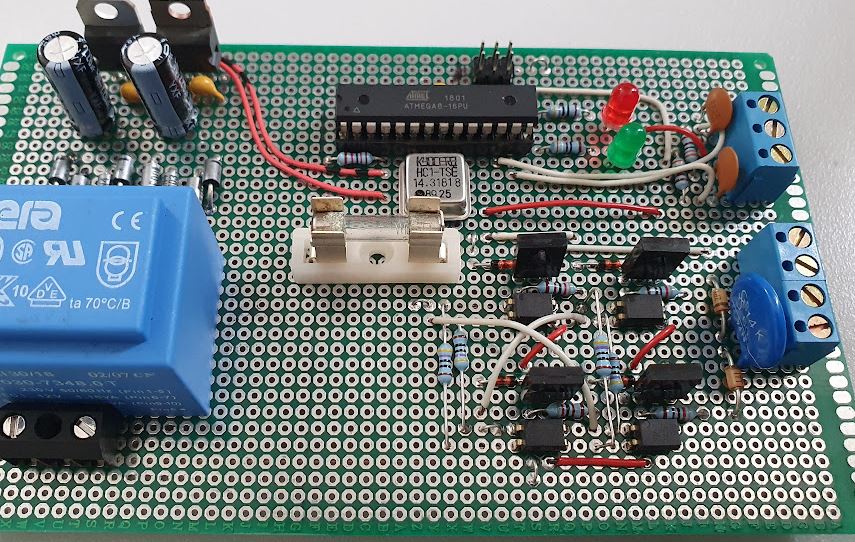

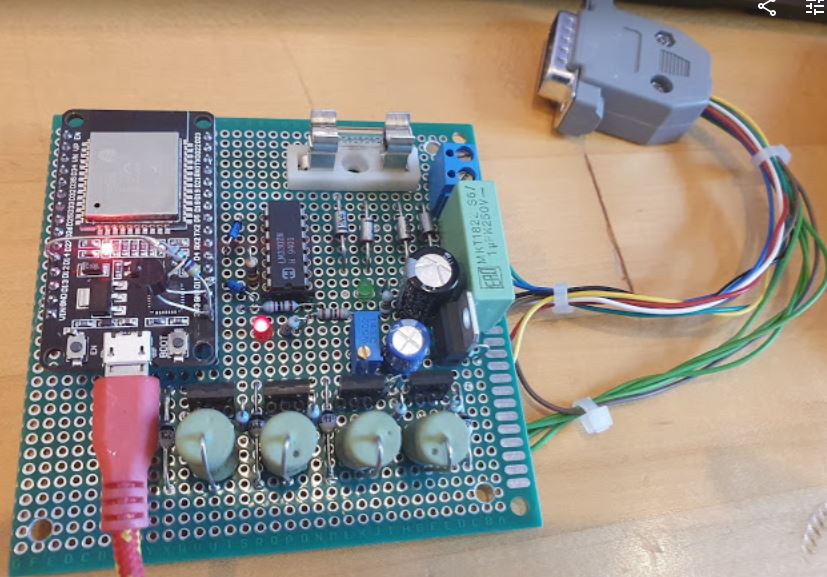

The internals, a arduino nano fake board (not running arduino code, but just some plain avr-gcc code), and the HX711 all wired up, we just need some hot glue to keep it together.

All ready to be put back together. Watch the wires, these are very thin.

The USB port, it all looks as if it had never been without.

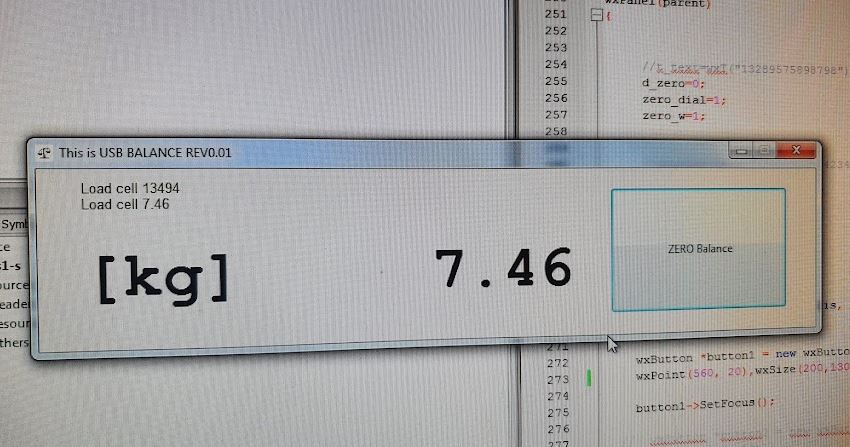

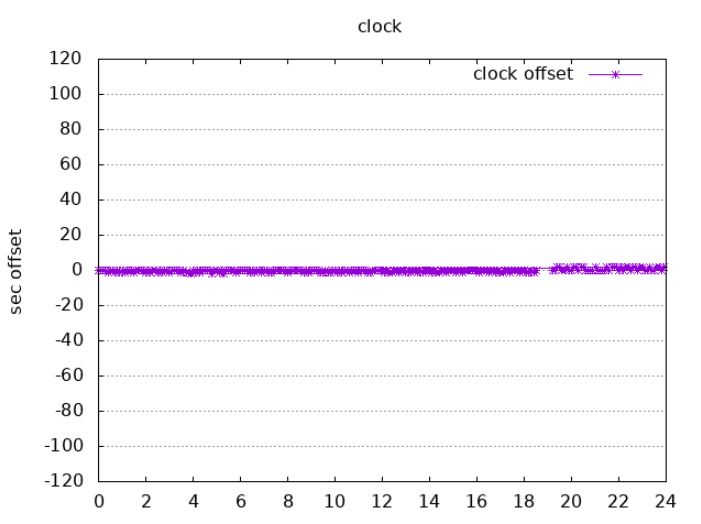

The receiver side, the balance digital converted value is directly transmitted to the host, so all the conversion to kg and zero correction is done by the host, including smoothing.

It is just a simple software, I programmed it using wxWidgets, but you can use any software that can handle USB/RS-232 communication and read serial ports, including Python, etc.

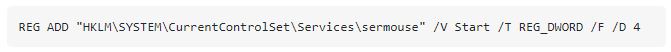

One bug with Windows – because of the continuous data stream over serial, Windows 7 seems to believe the balance is a serial mouse, and starts randomly moving the mouse pointer. With the little code below, this can be disabled and avoided. Probably need to add some waiting time before transmission starts in the AVR code.

If you need any of the code or further instructions, just let me know!

For calibration, a good hint, you can use milk packages (UHT milk), one pack is about 1060 g with very little variance, and it can easily be stacked up.

The Zero-Point seems to be very stable, I tested it after 90 kg load changes and so on, and it is not moving by 10 g.