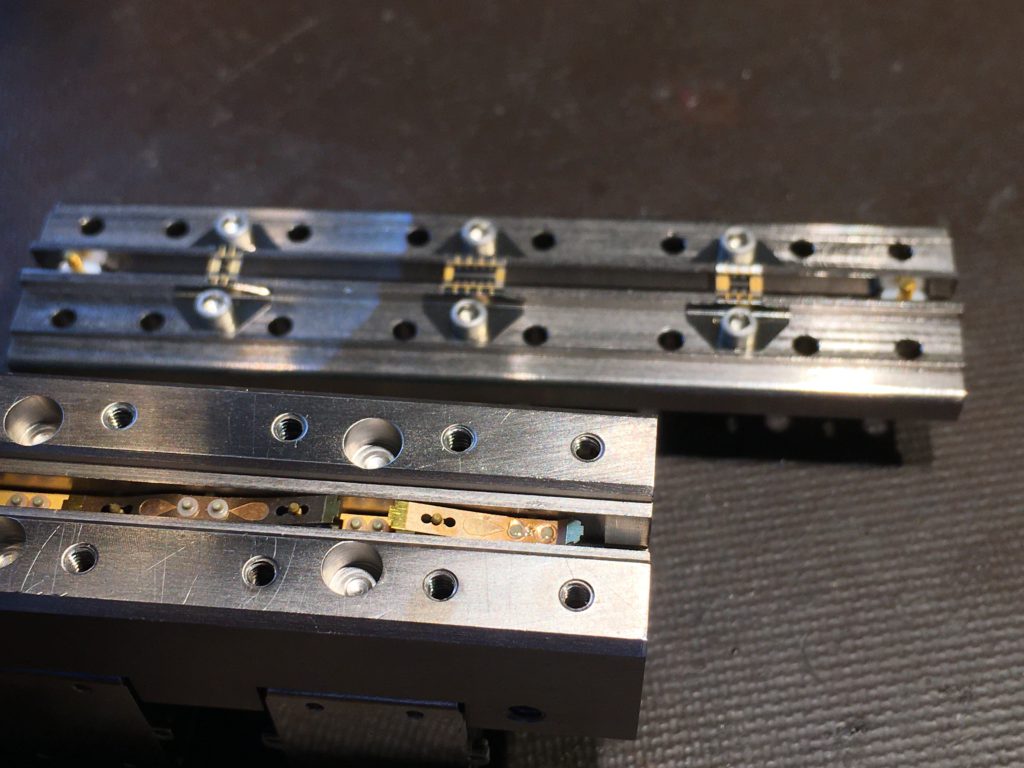

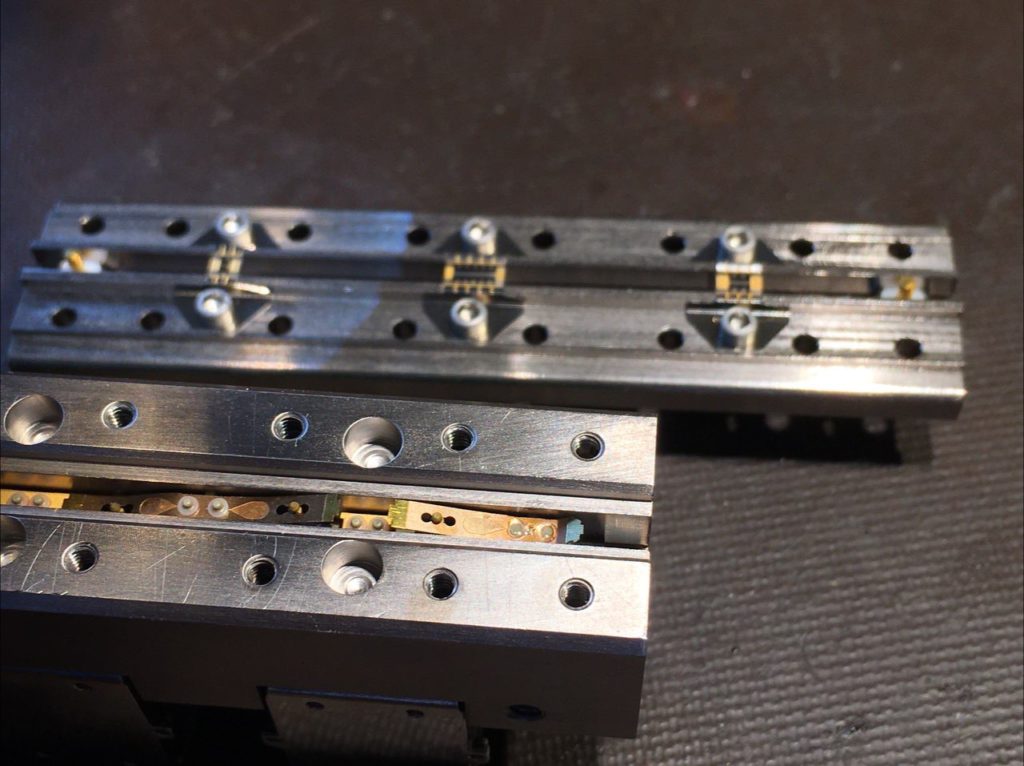

Thanks to a kind contributor there is a new way of fixing the HP step attenuators that are ubiquitous in the various HP and Agilent generators, analyzers.

These attenuators exhibit some common failures modes-

(1) blown pads – fix by replacing with pads from good donor units. Keep in mind that even if the pad value is the same, there are pads of different geometry/length!

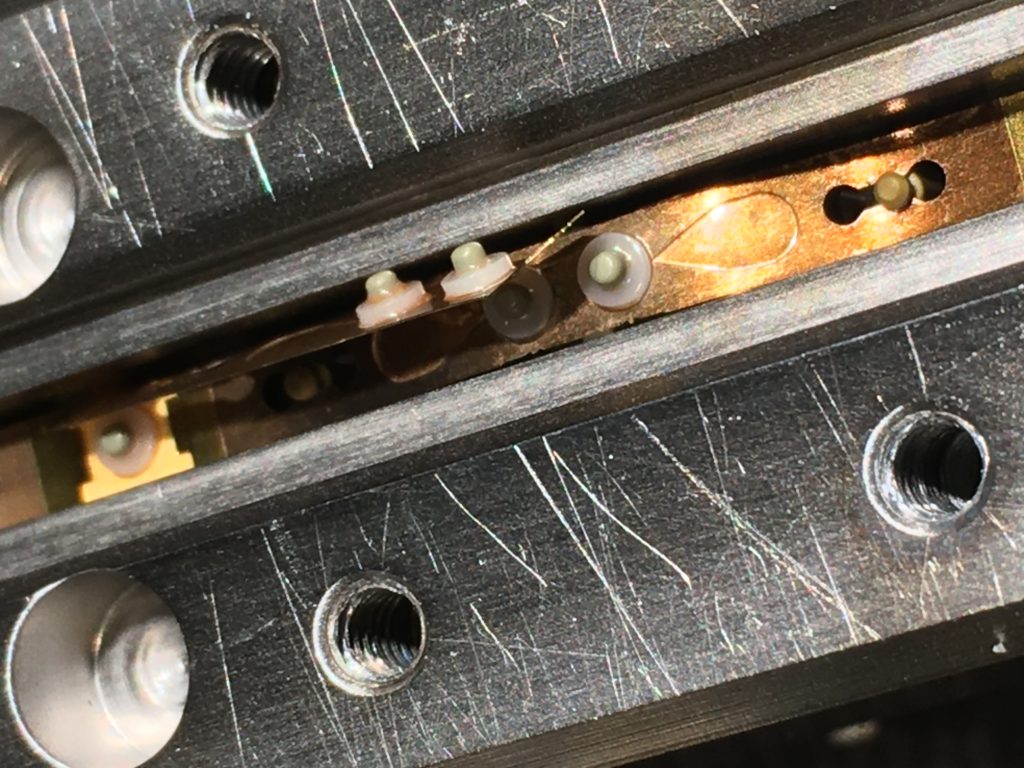

(2) mechanical issues with aged O-rings, easy to fix, best use some FKM O-rings

(3) the broken-off contact fingers, difficult to fix unless you have some precision equipment like a good milling machine or fine drill.

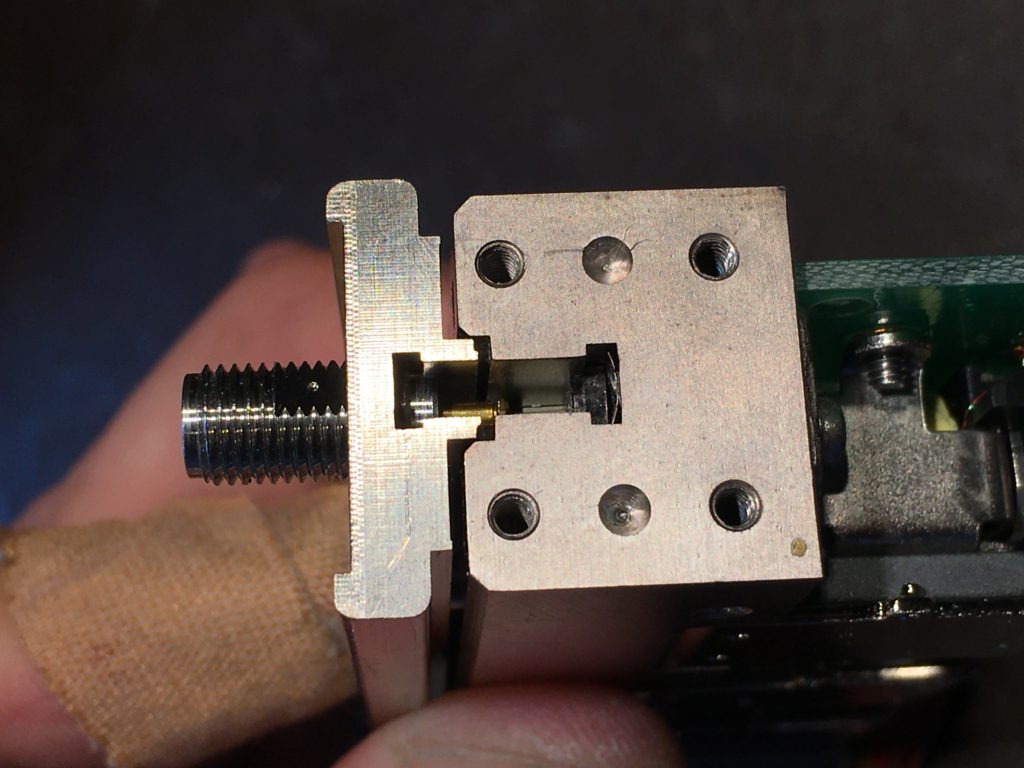

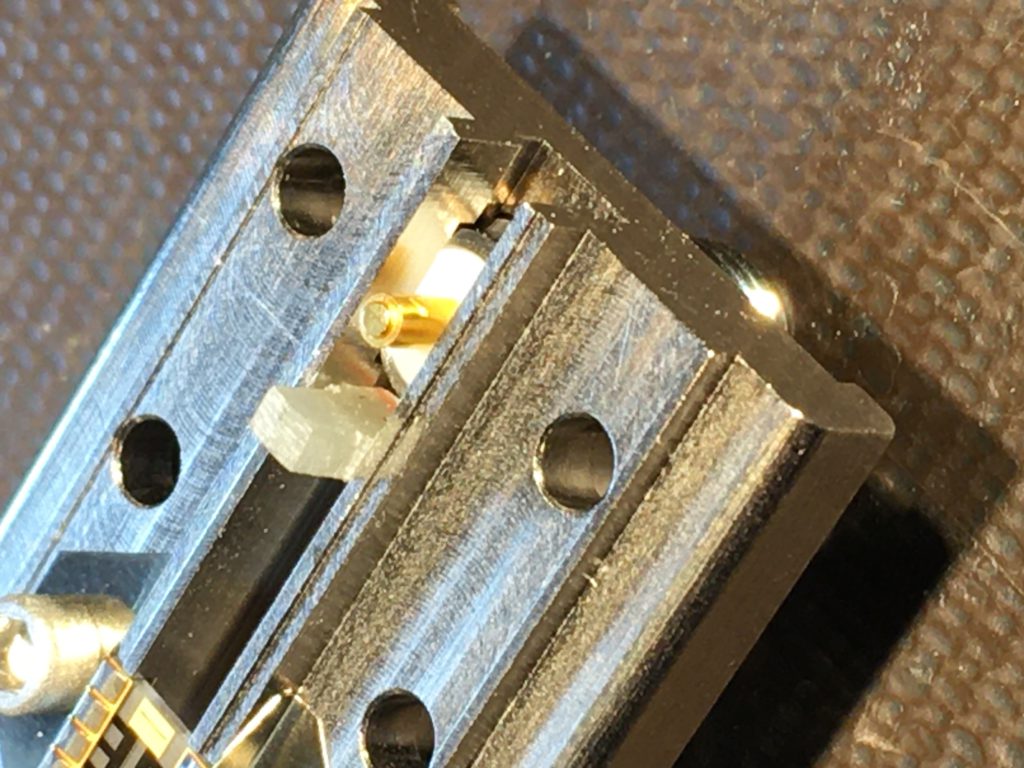

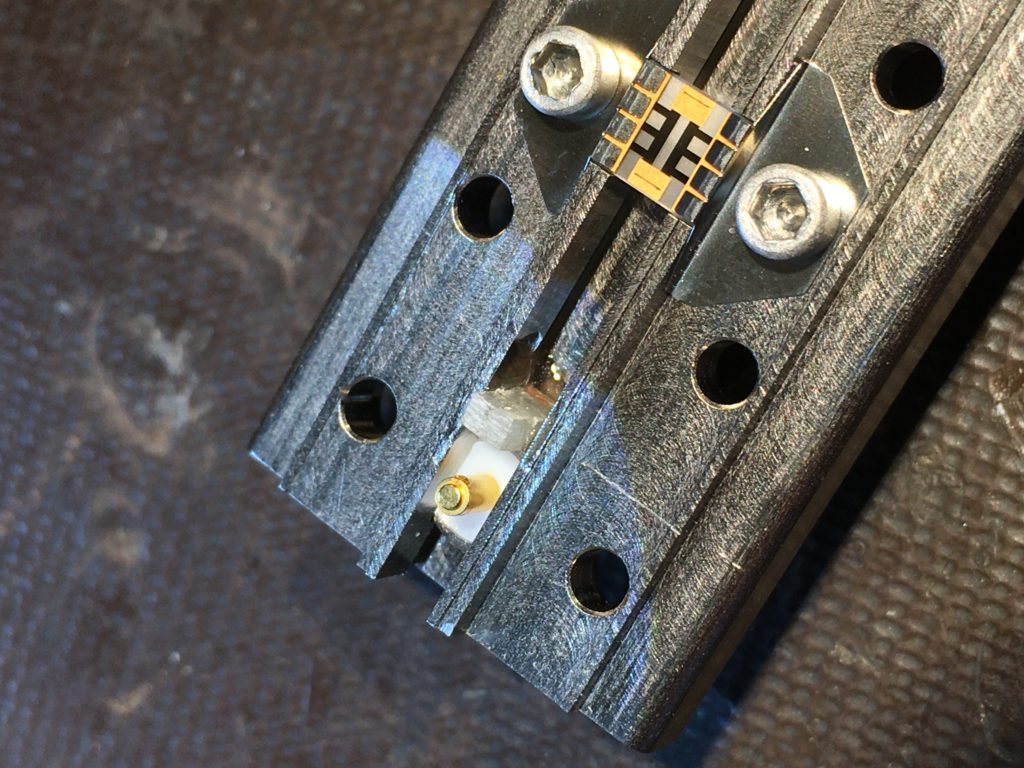

Here is an alternative way to fix it – use some two component epoxy glue after removing the remaining plastic parts from the contact finger by heat (heat gun or hot plate, about 200 degC).

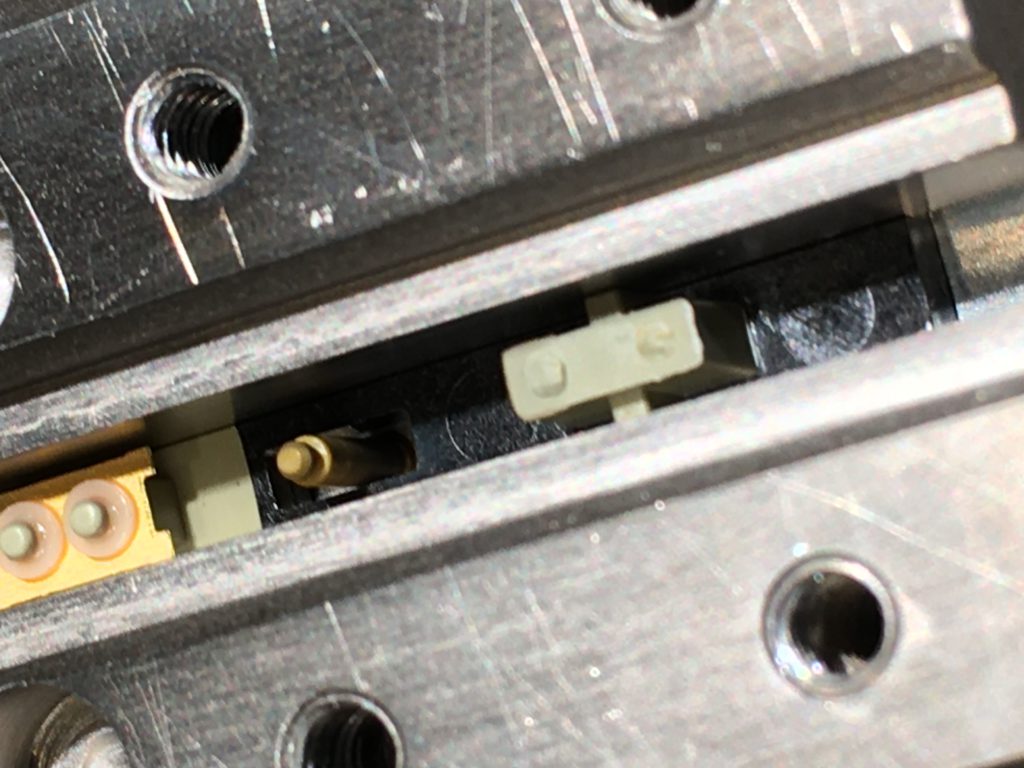

To ensure a permanent repair, a piece of FR4 is affixed with epoxy glue. Sure enough this is not quite ideal for high GHz frequencies, but no problem up to 2 or 3 GHz.

To clarify: the FR4 “bit” presses down onto the freshly glued contact spring. The idea being to reduce the mechnical stress on the minute glue surface area, so to avoid the contact spring coming loose while switching.

Wilko

PA1WBU