Quite a few good tutorials exist for anodizing of aluminum, and pretty decent results can be achieved in any home shop equipped with a a sink and a few chemicals. For good results, with all the basic items mastered, the most critical item is the aluminum alloy. Generally speaking, any type of pure aluminum, and Al-Mg alloys are very much suitable for the anodization process. Zn, Si, Mn (and to some extend, Cu containing) alloys don’t work well.

The handles for the Micro-Tel MSR-904A receiver were machined from 7075 alloy, because of its strenght, and availability. 7075 has about 6% Zn, and 1.5% Cu, both of these elements are known to cause trouble when anodized. However, one can still try.

A quick, step-wise description of the process:

Step (1) – throughly clean/degrease the workpiece: first, I use methylated spirits, then, hot water and detergent, then rinse with water. Wear clean gloves.

Step (2) – etch with about 10% caustic soda. Room temperature.

As you can see, the part will turn black. This is typical for certain alloys.

Step (3) – use about 5% nitric acid to remove the black layer. Dip for a few minutes only. There will be some faint grey residue which needs to be brushed of mechanically (use a very clean brush – otherwise, it will contaminate the surface). Had to repeat the caustic etch twice to get a uniform and shiny surface.

Step (4) – anodize. Mount the piece with heavy aluminum wire. For 7075 alloy, pure aluminum wire works. Alternatively, use thick titanium wire. Current needed is about 1.5-2.0 Amps per 100 cm2. I used 2 A, for the handle. As cathode, use a sheet of aluminum, lead, or titanium. I use just plain aluminum and it is working just fine. For the liquid, about 15-20% sulfuric acid (dilute 37% battery acid with destilled water 1:1 ratio). Keep at room temperature, cool with some ice (applied to the outside) if it heats up too much. Typical time needed is 30-60 minutes, depending on the temperature and layer thickness. Don’t let the acid heat up too much – the layer will stop growing.

Step (5) – densify by boiling in distilled water. Needs to be really boiling, not just hot!

After the first attempt – everything looked fine after step 4, but the handles turned pretty dark after densification.

Pretty much, a full failure.

So, etched off the oxide layer with 10% caustic soda, and repeated the process, with two modifications:

(1) Keeping the acid rather warm, about 30°C, and reduced anodizing time to 20 minutes. This will give a thinner layer.

(2) Added a bit of ammonium acetate to the water used for densification. You may also add a very small amount of acetic acid. Keeping the bath slightly acidic prevents darkening during the densification process for Zn/Cu containing alloys.

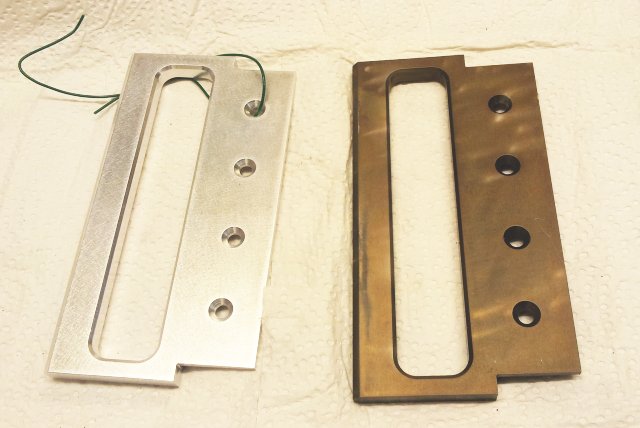

The final result:

It’s not perfectly silvery color, but a slight yellow-orange color (like lightly colored wood). And the layer is certainly not very thick. But good enough to protect the 7075 alloy from forming corrosion spots over time.