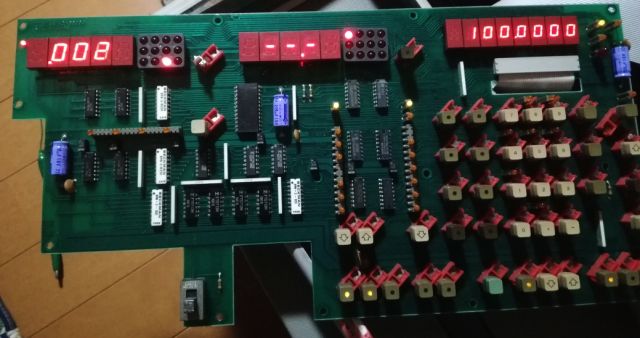

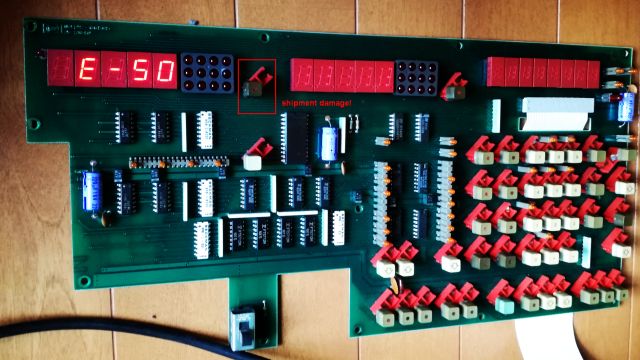

With some success, and power supplied at proper voltages to all assemblies, we can get into the inner workings of this marvelous unit. There are issues, all kinds of UCL messages and E-07 during calibration. Connected a 1 kOhm resistor as a test device, and played around with the ranges and frequencies, and some luck – at 1 kHz, and with manual range selected, I do get a proper measurement (but not in the other ranges), at higher freuquencies, no measurement possible, the bridge is not balancing.

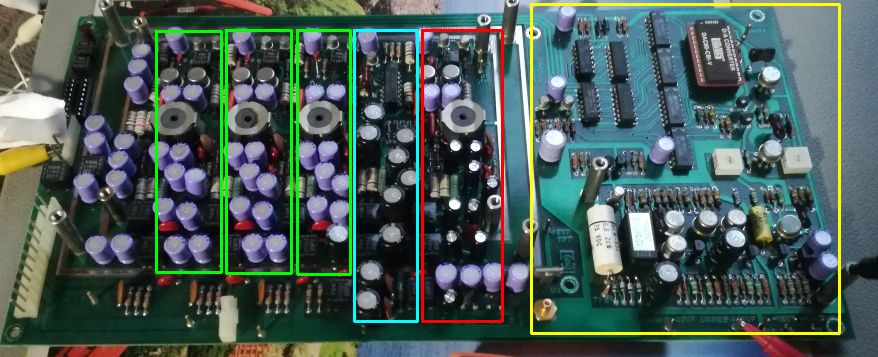

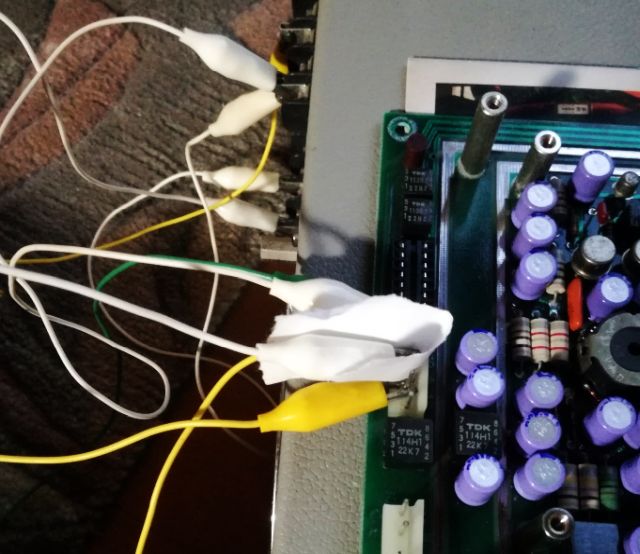

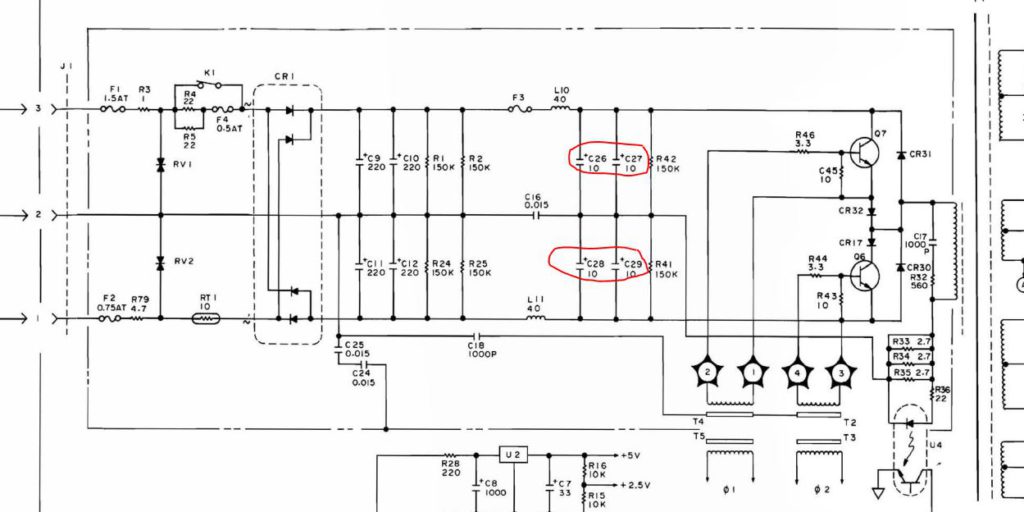

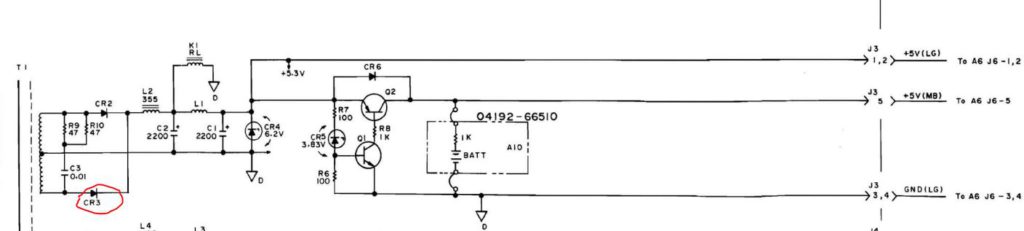

So, let’s take it step by step. First we need to check the source assembly, A1, or part of it – quickly found out that the supplied voltages and source resistor switching (by mechanical relais, therefore it is a good place to check – but difficult to fix, because there is all kinds of magic around these relais to eliminate parasitic capacitances – you can’t just put in any ordinary spare part). All is good with the source assembly.

Also the inital stages of the receiving section and the mixer, working fine. These circuits are part of the so called process amplifier, A11 assembly. The whole input circuits, please be careful, there are many precision parts and FETs and expensive things – don’t damage it. And it is pretty complex, so don’t get lost.

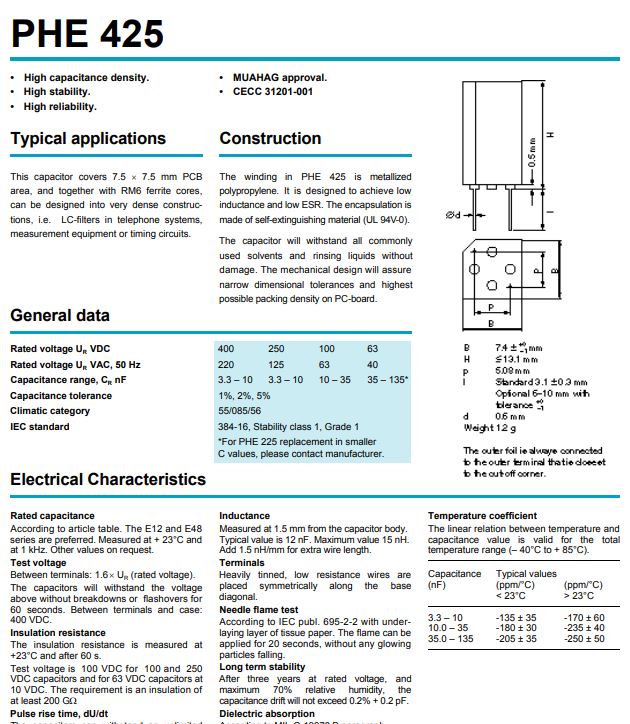

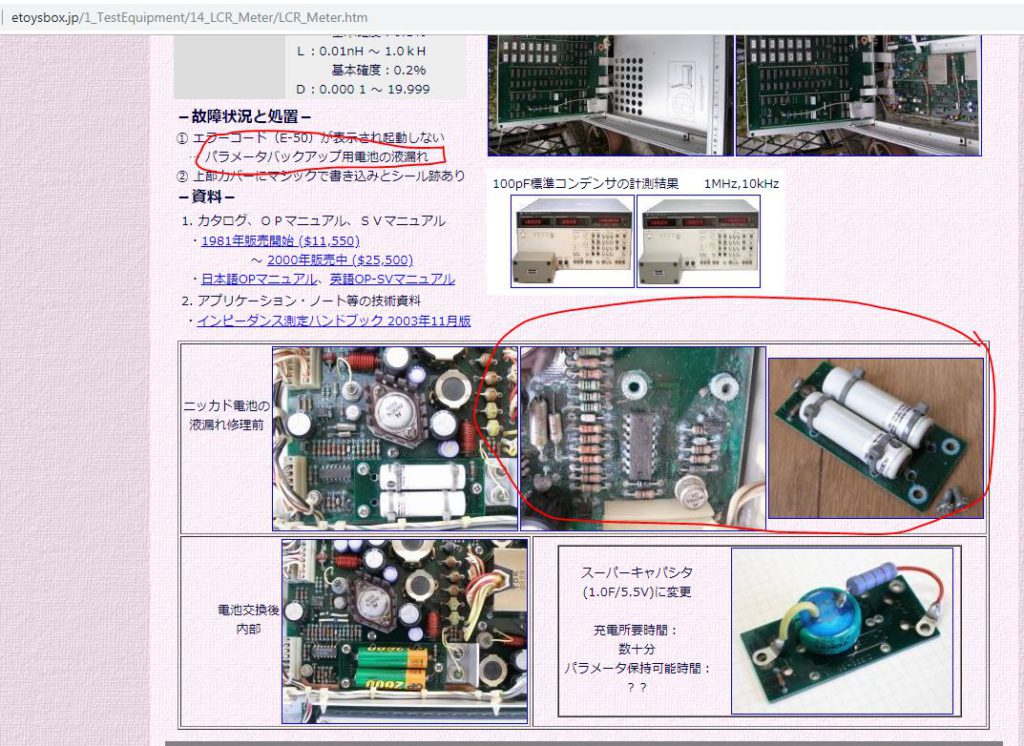

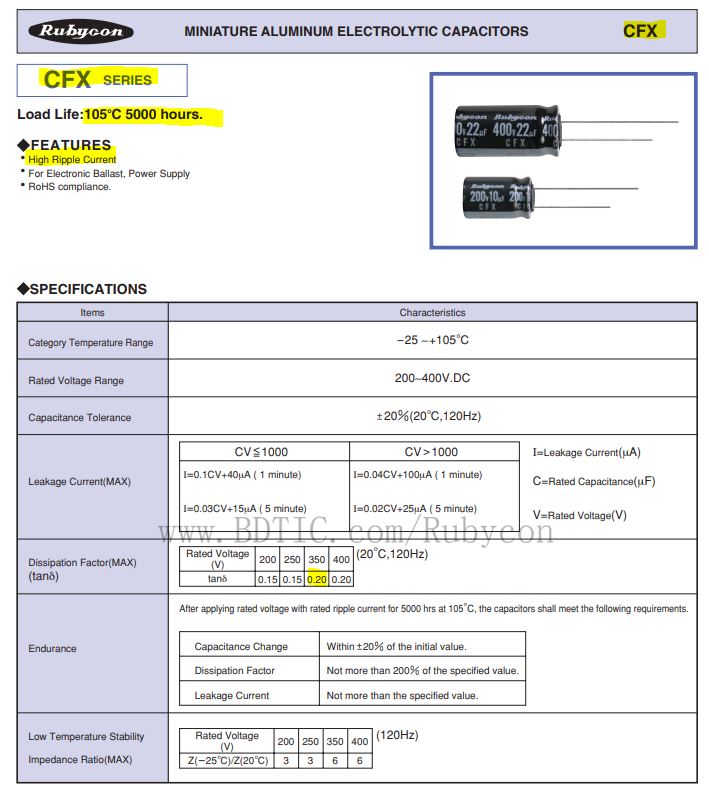

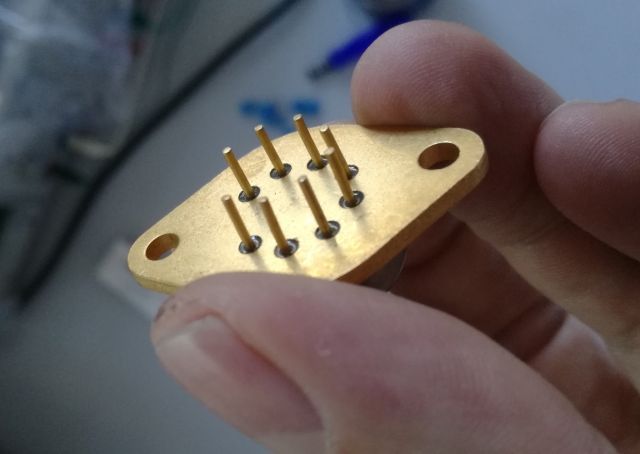

Along the way, an interesting part, a RIFA precision PHE425 cap.

The “F” in 22nF is not actually Farad, but the tolerance denominator of Rifa, meaning, 1 % tolerance. The caps have very good data, very low drift over time, and a very low voltage and temperature coefficient. Maybe I will consider these for own designs, filters, and so on.

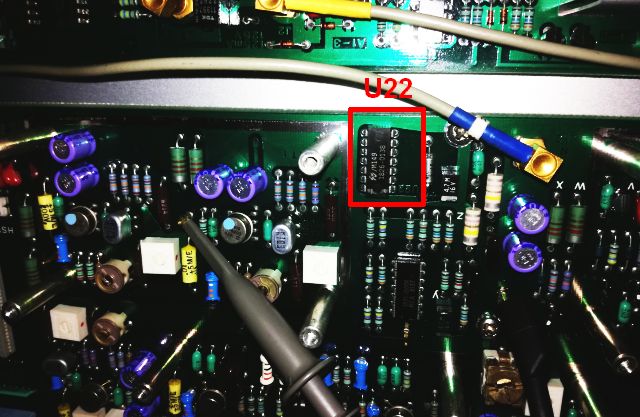

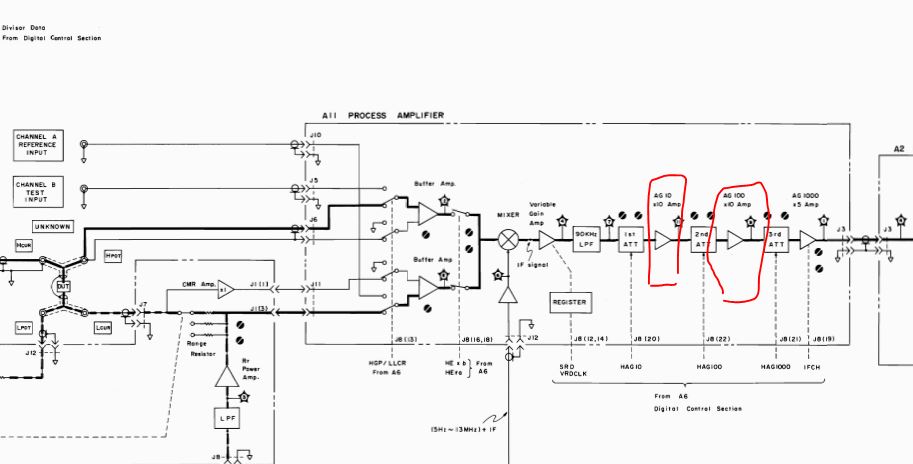

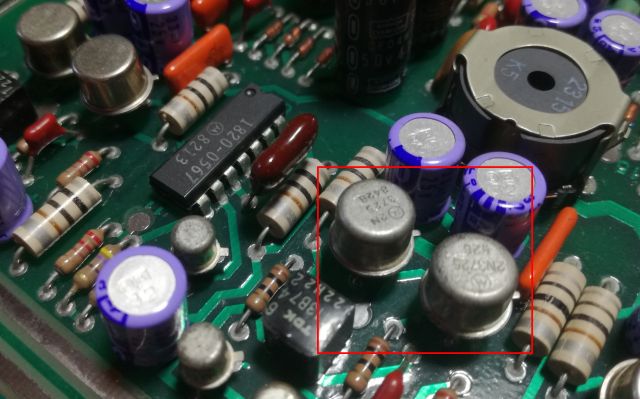

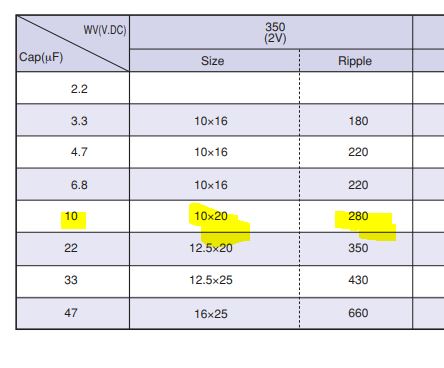

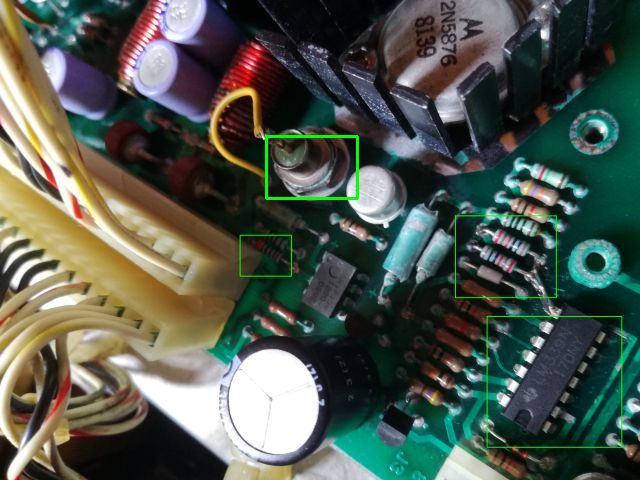

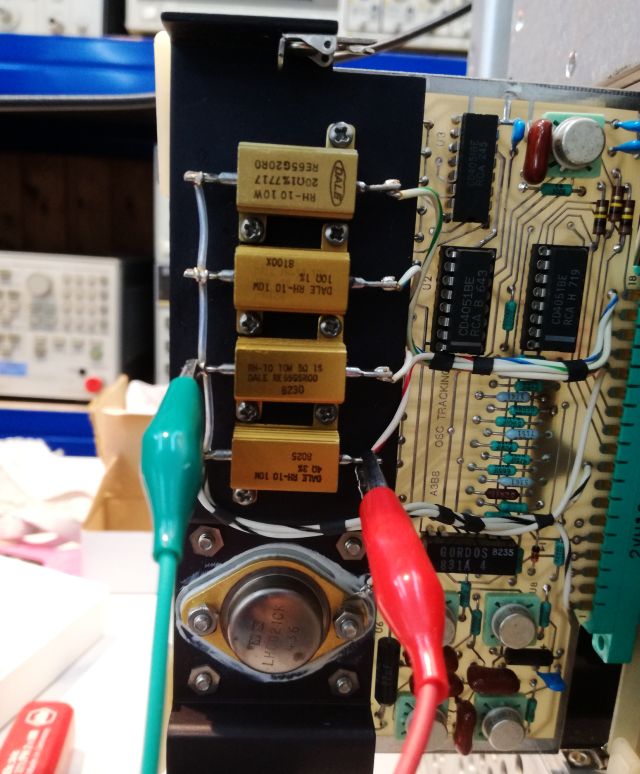

Testing, and testing again: found an issue with the IF amplifier – it is not switching the amplification properly, it is overly amplifying the signal (locked in x10 mode). No wonder it doesn’t work at high frequencies as it will saturate the following circuits.

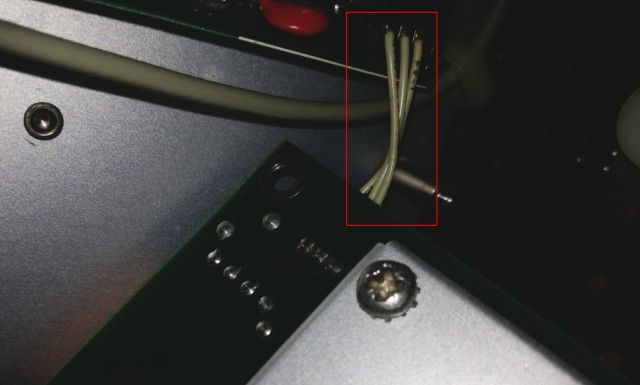

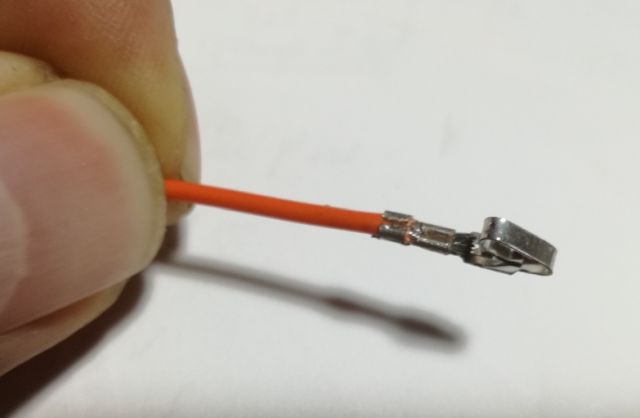

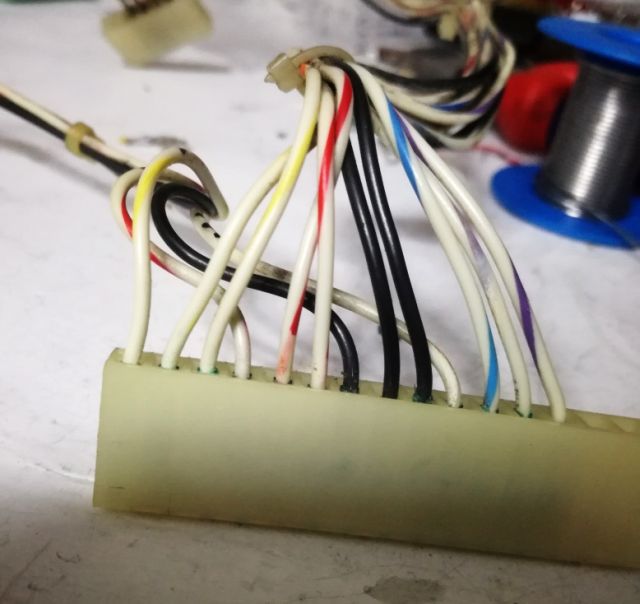

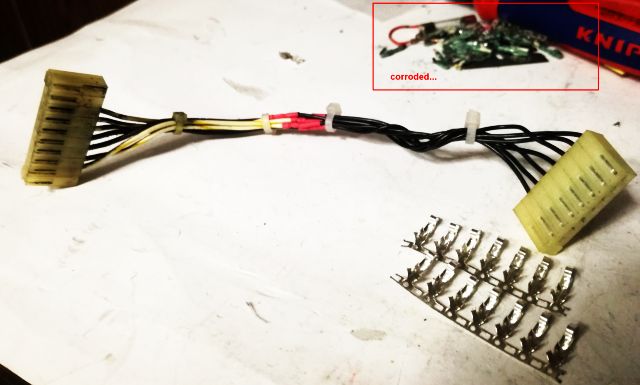

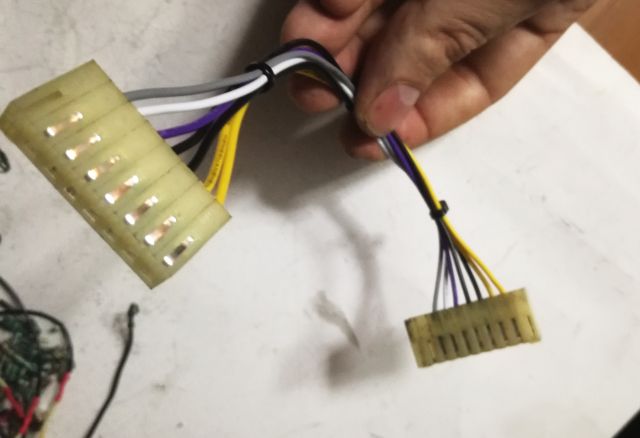

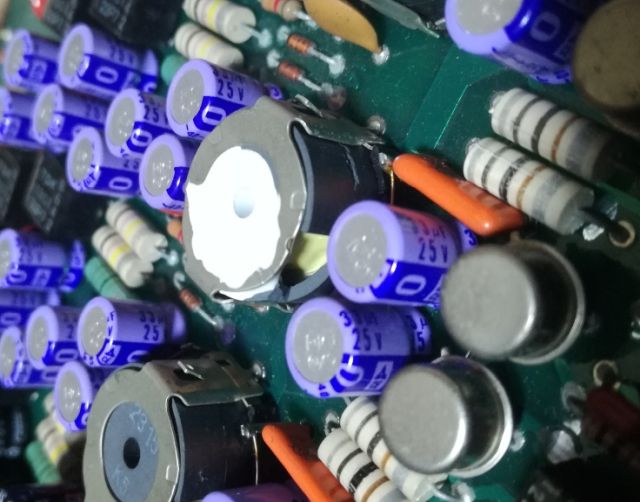

The A11 board, it is not as service-friendly as usual, because it is connected to the A1 board by 3 wires that are soldered to the board, in a narrow space (no plug!).

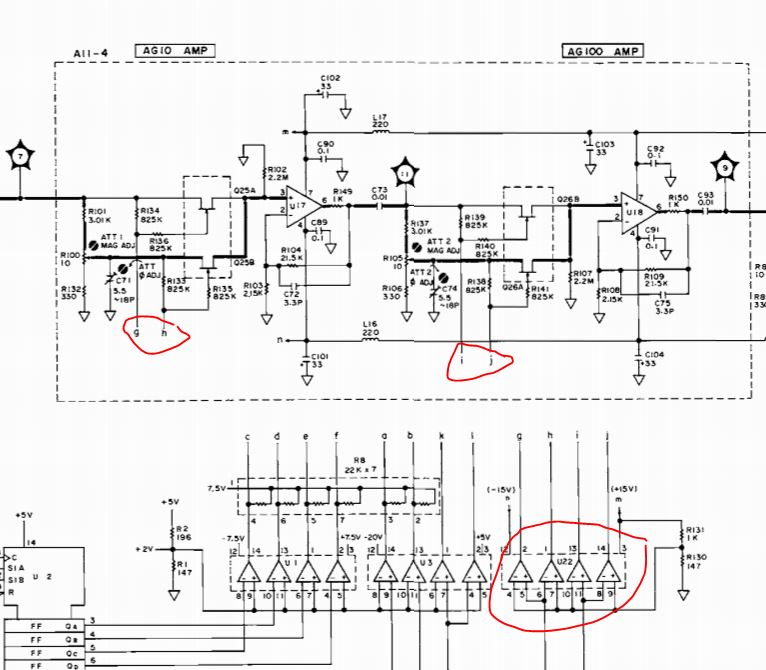

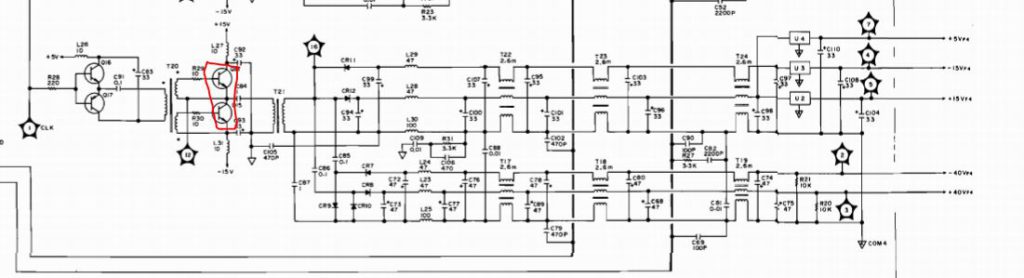

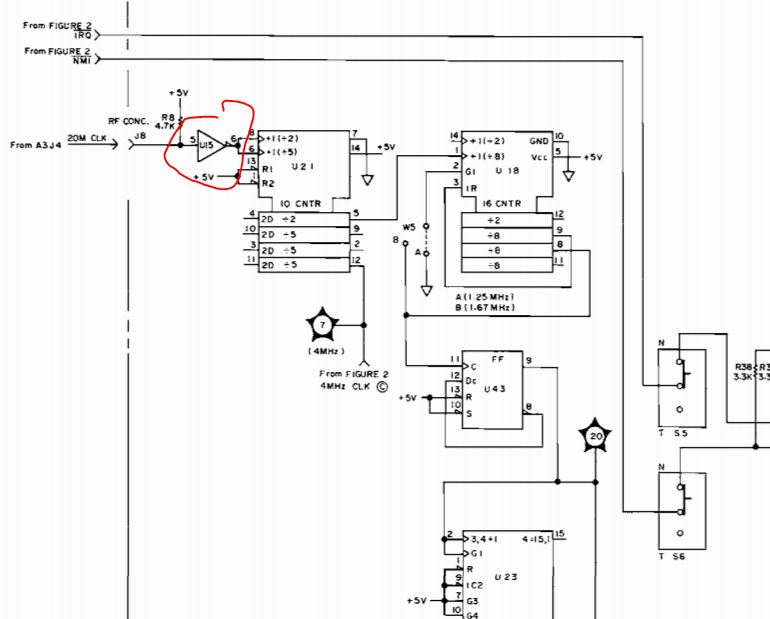

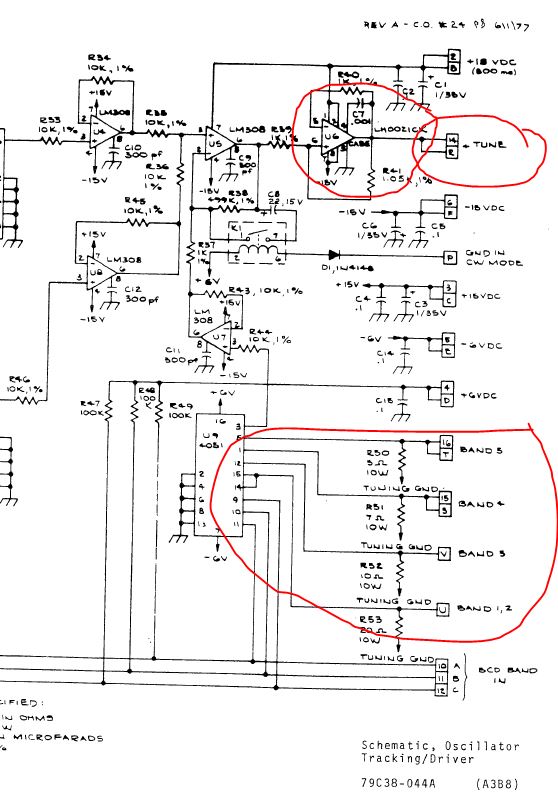

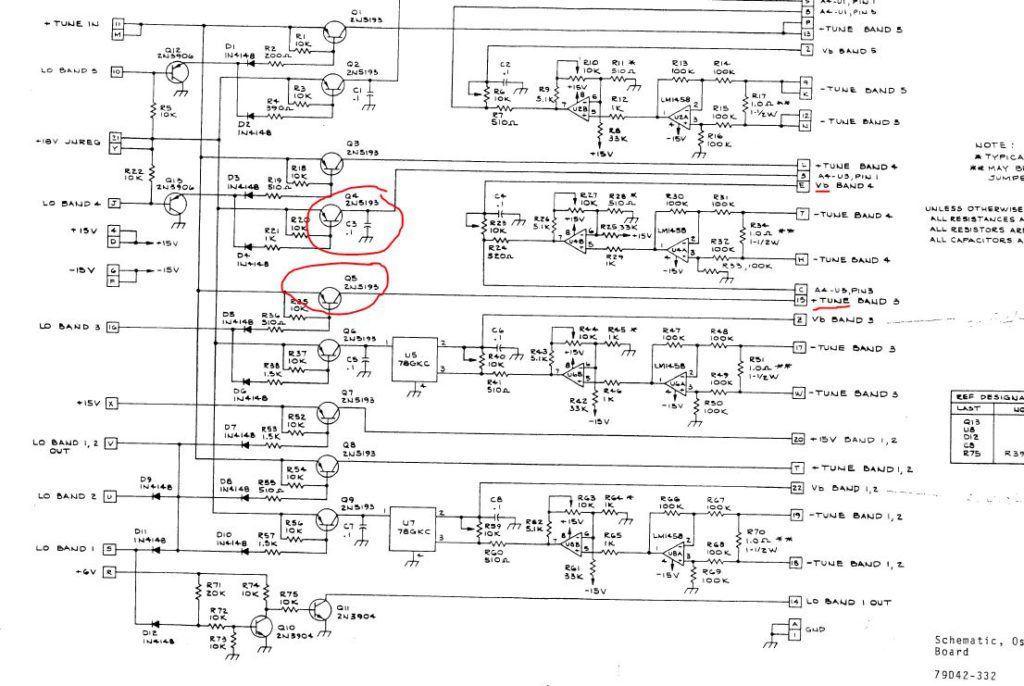

In the block diagram, you can clearly see the x10 and x100 amplifiers.

These are controlled by a quad comparator that is set by the controller assy.

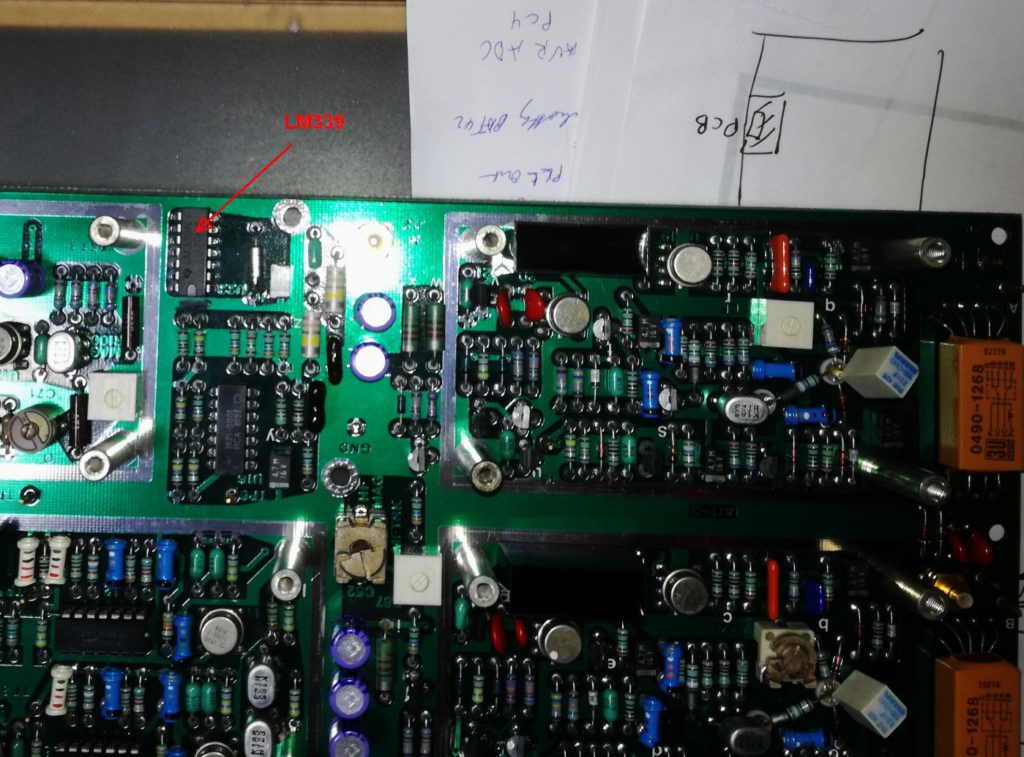

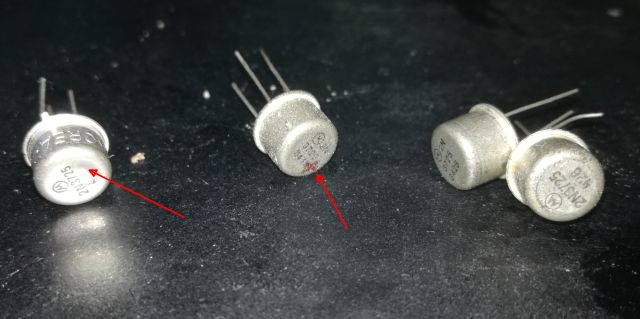

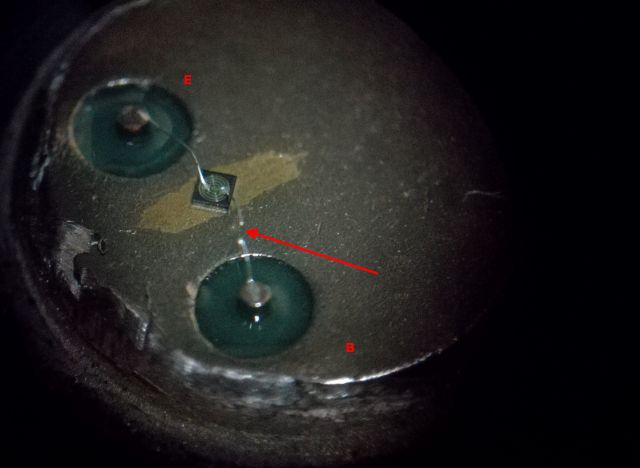

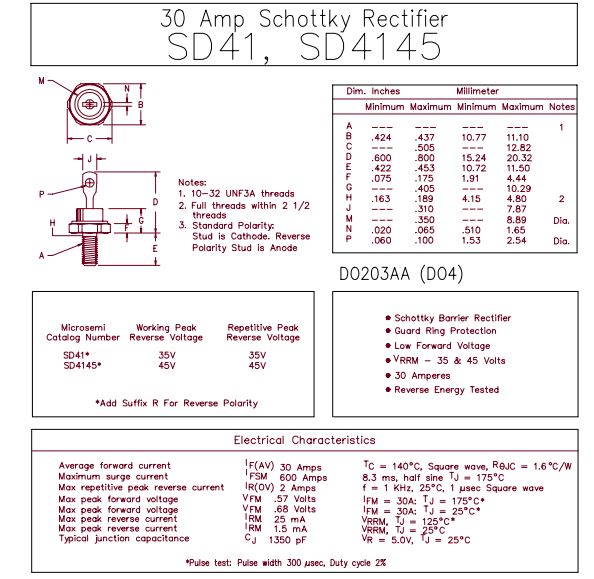

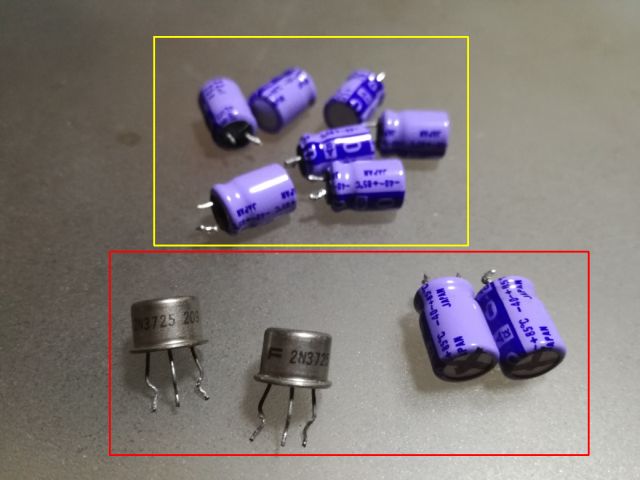

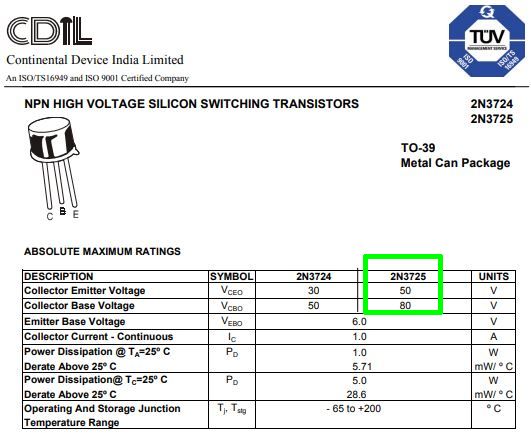

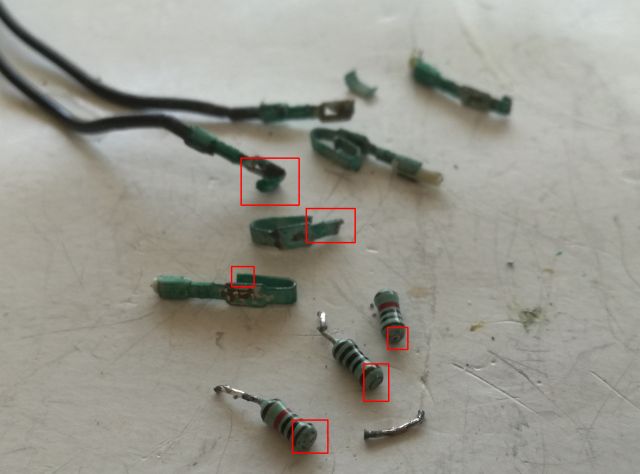

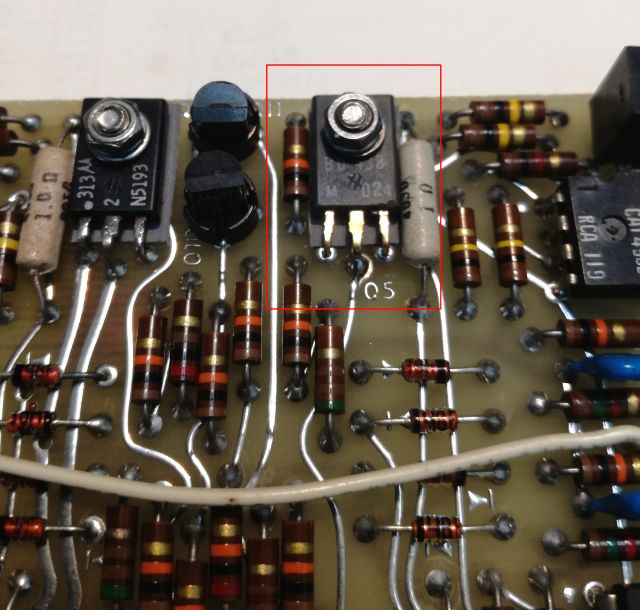

Some LM339’s are in stock here, it is one of the most essential parts to have in any electronics workshop. The LM339 is the equivalent to the HP 1826-0138. It is run at over 30 volts supply (-16 to +16 V), maybe it got damaged during the power supply failure and some related surges. But the 1826-0138 HP parts are also known for some age-related failure, at least I have already replaced a few others in HP instruments.

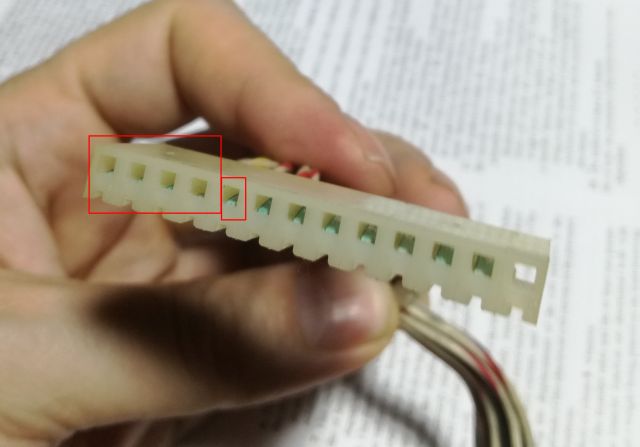

The bad part – causing all the trouble.

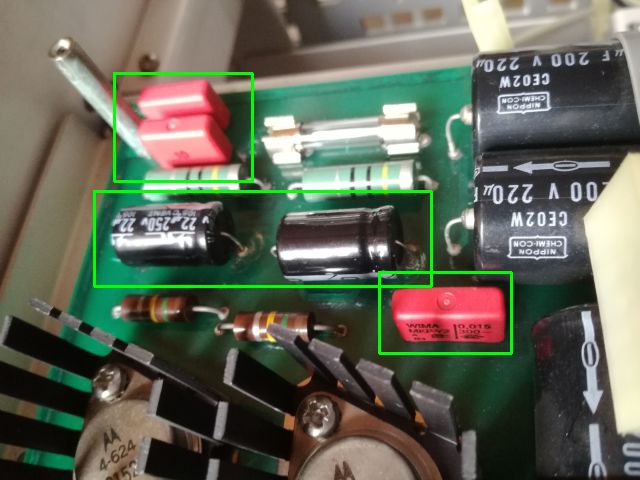

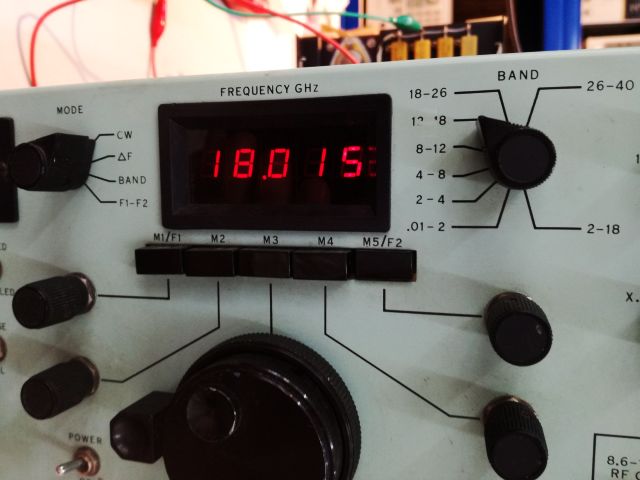

Quite some extensive tests later, I decided to put the instrument back together (many of the shields still removed), and had it run for a day with no problem. Self test and calibration is working at all frequencies. Adjusted the phase balance, the amplifiers and attenuators according to the manual’s instructions. Adjusted the power supply after due warm up. Not much adjustment needed. The bias supply, it is as good as the test equipment I have here, will need to do some tests later in Germany with some better voltmeters.

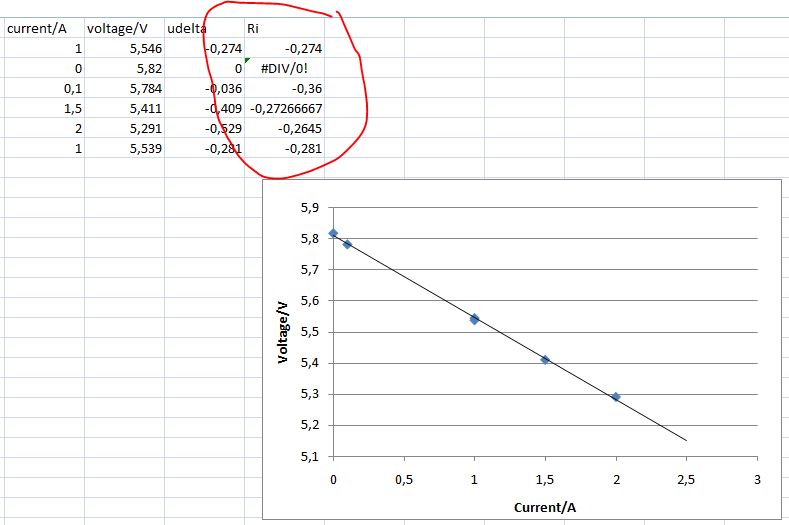

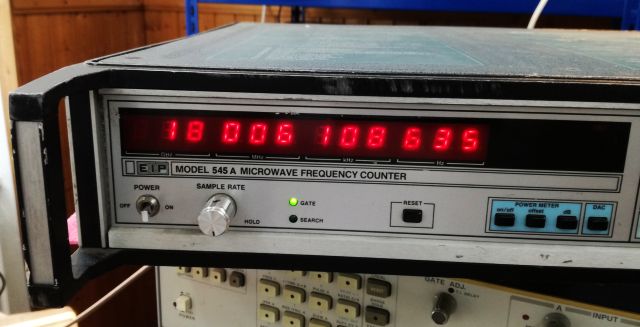

Some test measurements – using a 1 kOhm, and a 22 nF capacitor.

Also, still needed from the stockpile of HP spares back in Germany – a push button cover (the switch itself is working).