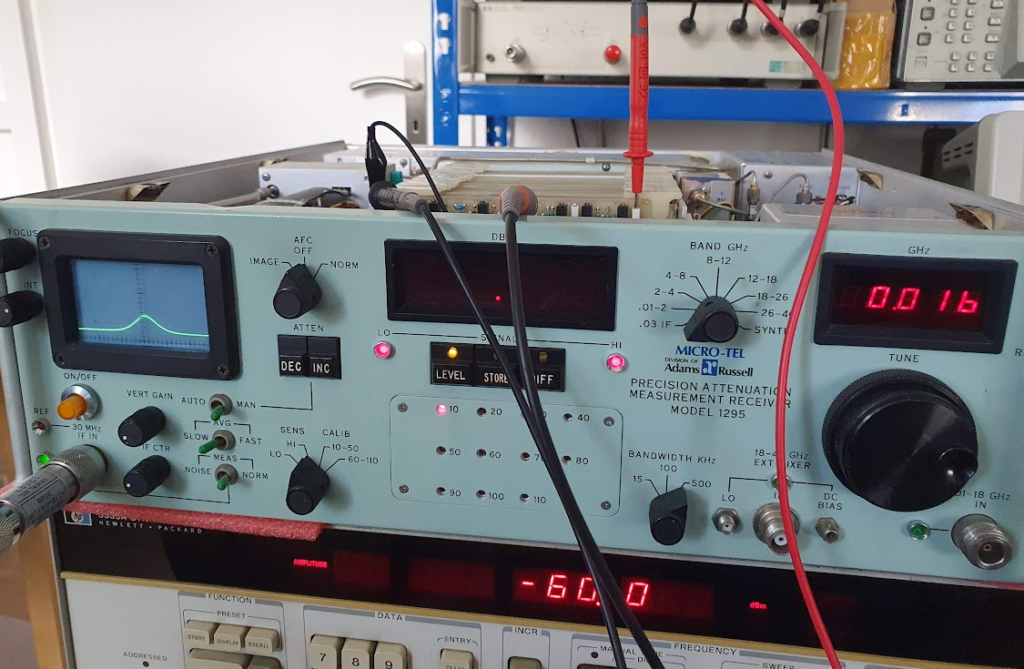

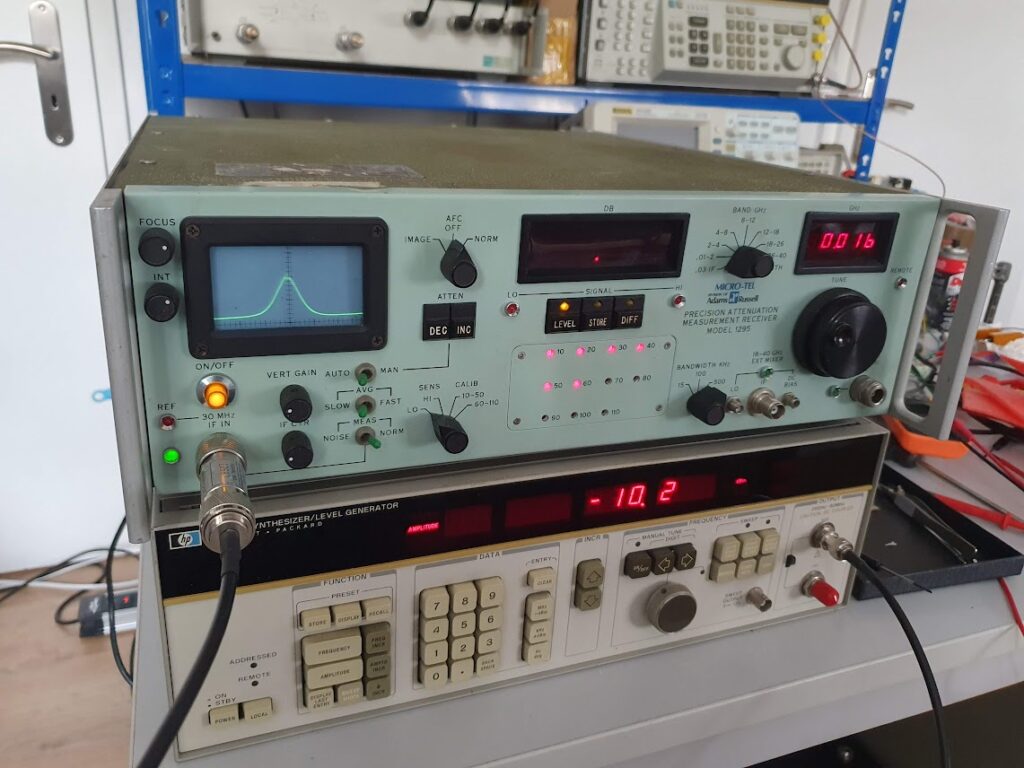

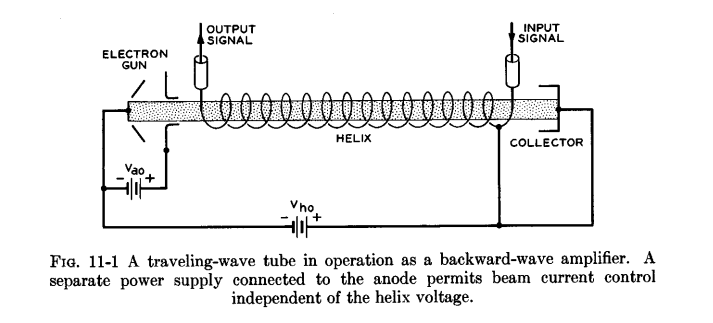

I am trying hard to resist the temptation of buying more test equipment, but the Micro-tel special green color has a hypnotic effect on me, and combined with the right price, I could not resist to buy one more Micro-tel 1295 receiver. These are very capable 0.01~40 GHz fundamental-mixing receiver (fundamental mixer until 18 GHz, above that, harmonic mixer), with very large range, like, 120 dB, and 0.001 dB attenuation resolution. Ideally suited to calibrate attenuators or to check antennas, etc.

The unit – offered as non-working – arrived very well packed. Unfortunately, many people send sensitive equipment in some thin cardboard boxes. This particular equipment cost close to 85 kEUR in 1989, plus mixers. Also, it has long been under export control from the US, because of its unique range and accuracy.

Bubble wrap, other fibre wrap inside.

Finally all in foil.

The defect, it doesn’t show any reading on the display, and both the HI and LO leds are on, which is abnormal. The 1295 has a 12 dB range bolometer detector, any signal below 0.5 dB or above 12.5 dB will light up the LO or HI lamp, and you would need to select another 10 dB step of the IF attenuator (a high precision 30 MHz attenuator), or let the automatic attenuation selector do the job.

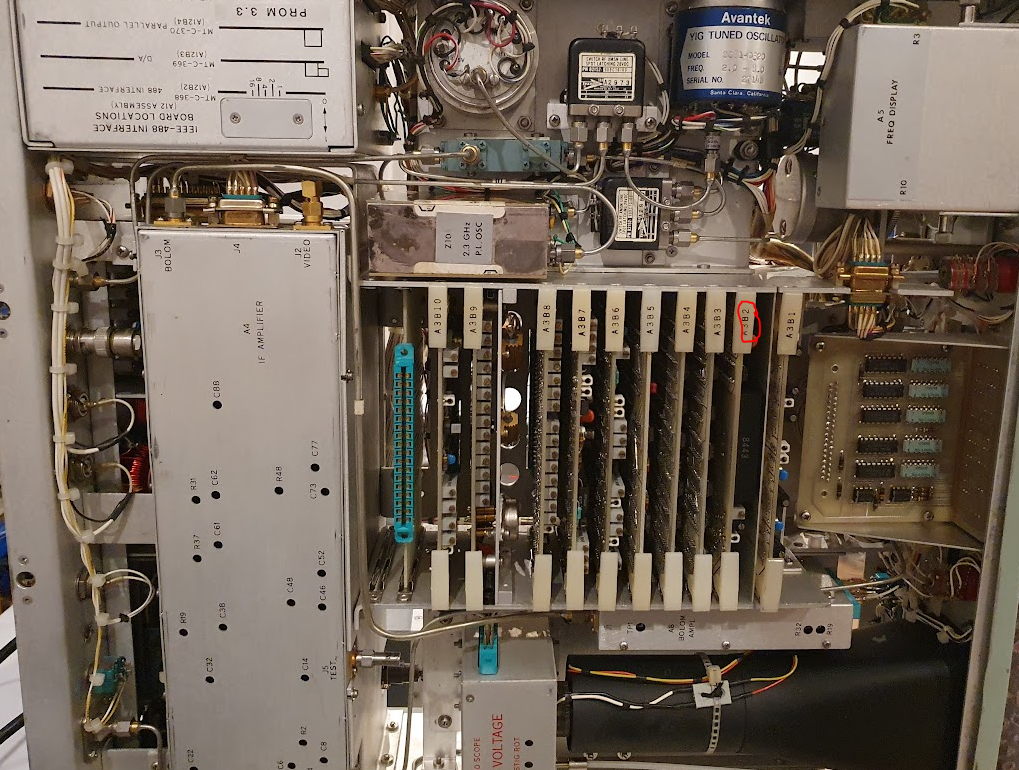

There are many boards inside, but all nicely numbered and with instructions in the manual.

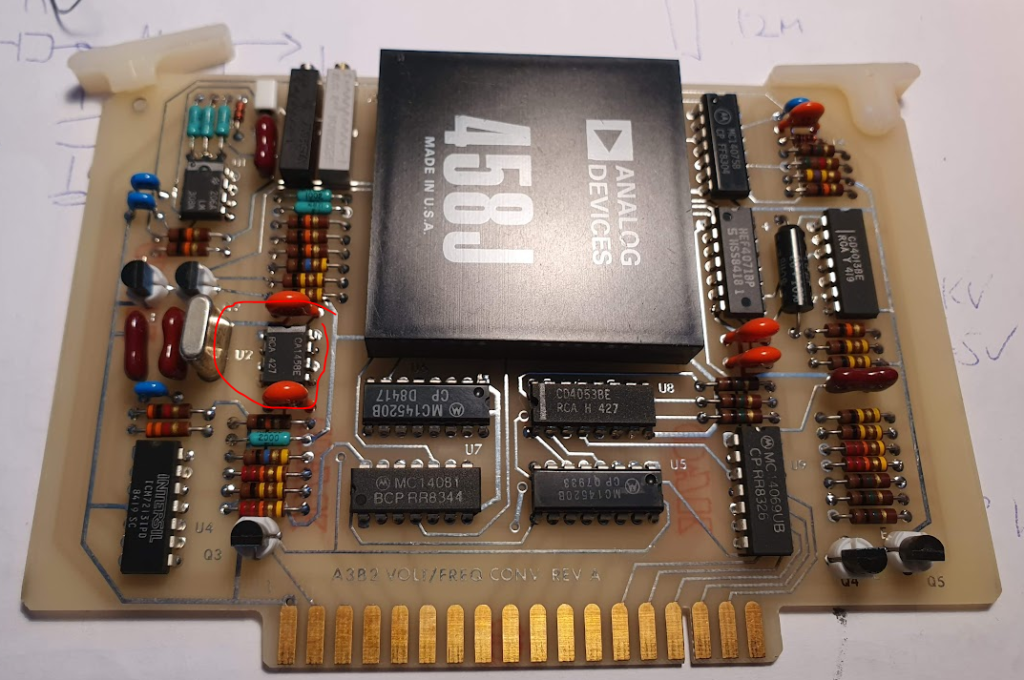

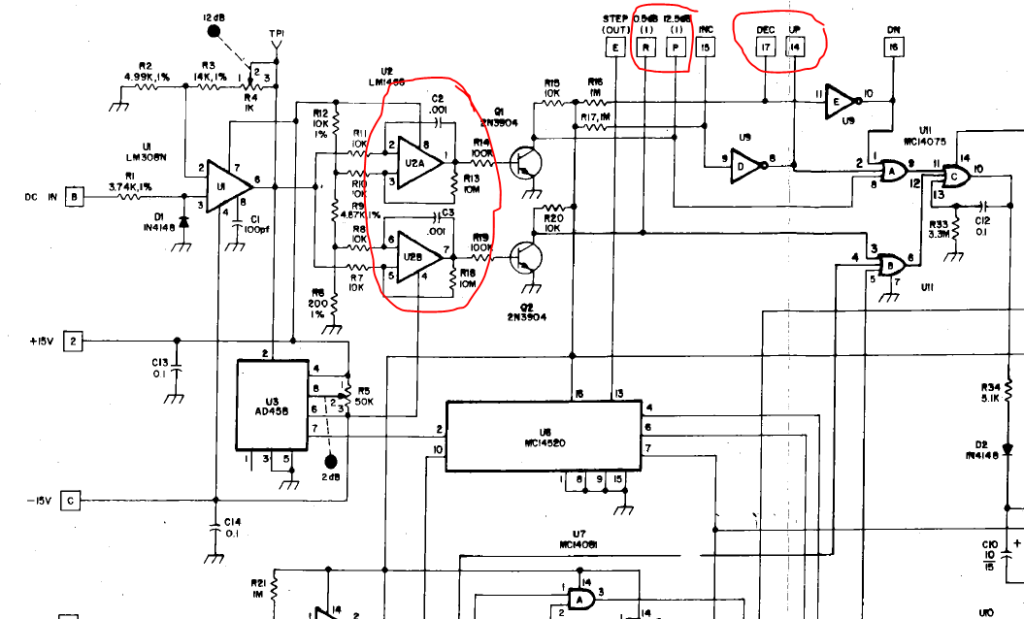

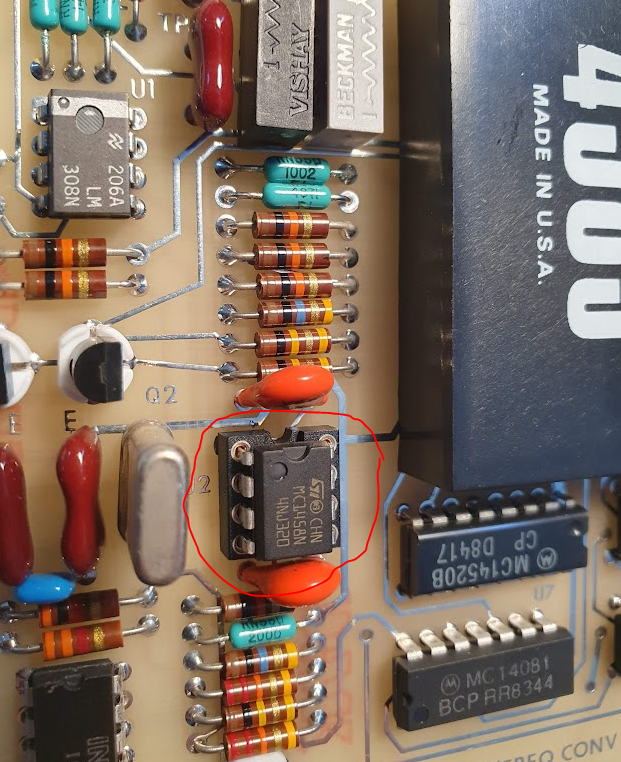

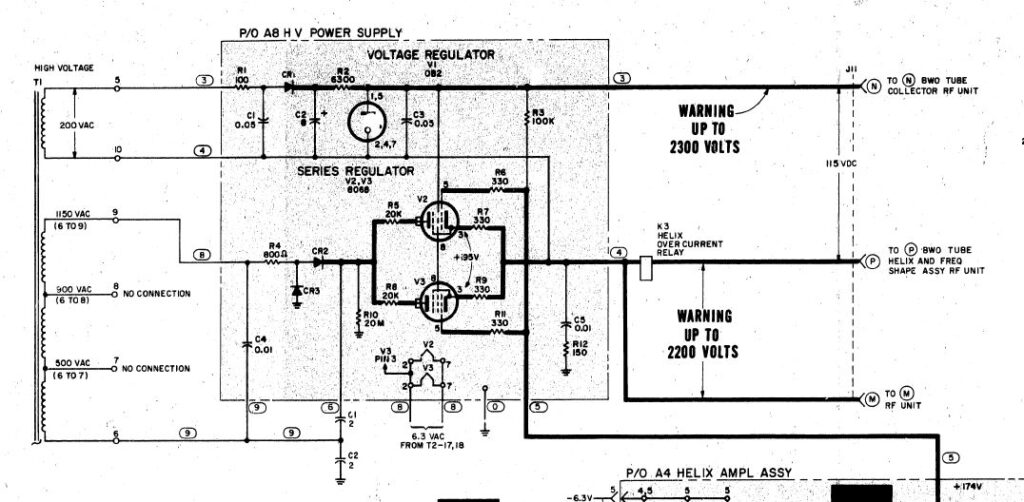

The HI and LO level detection is done on the A3B2 assy.

According the the schematic, U2, a MC1458 generic dual opamp is switching the LEDs and providing signals to drive the automatic attenuation selector.

A quick check revealed that U2 is defective, so I replaced it quickly, and this already solved the issue and brought back the display.

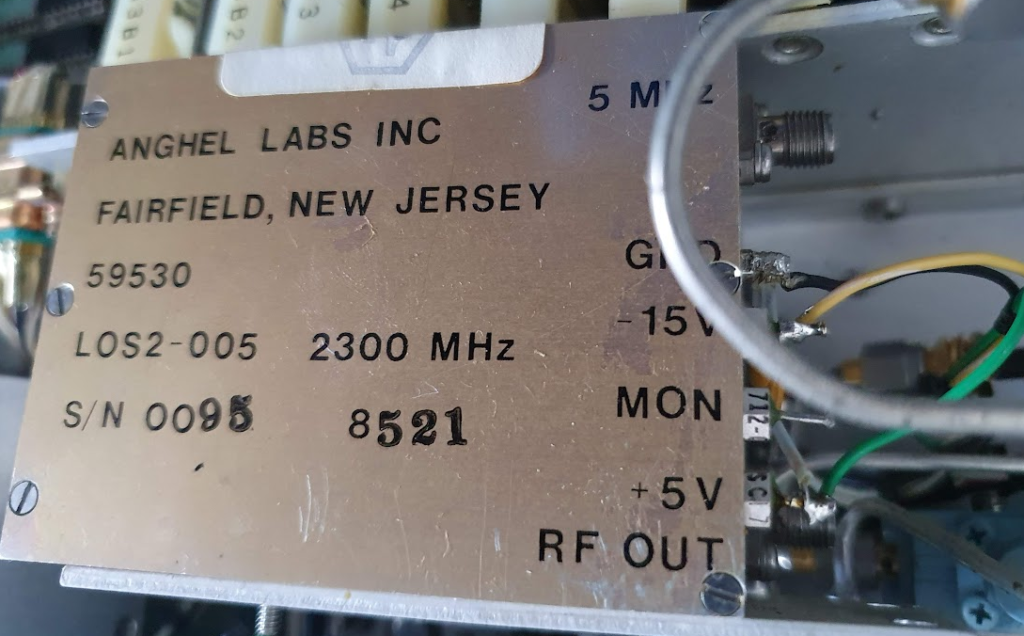

Another trouble related to unstable lock of the 2.3 GHZ auxiliary LO that is used for the 0.01-2 GHz range (which uses a two-stage down mixing).

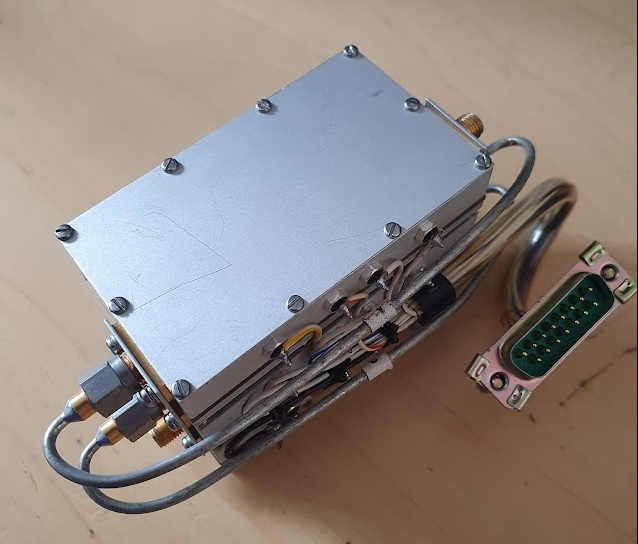

Fortunately, I had a spare 2.3 GHz from my parts unit (which I bought years ago – a partial unit – while I was living in the US). That part was missing one of its covers, and had also some issues earlier, but I had fixed it a while back just for curiosity. Now I can fix the unstable 2.3 GHz removed from the unit during next winter. It has a 2.3 GHz VCO, a 100 MHz local oscillator and a PLL inside.

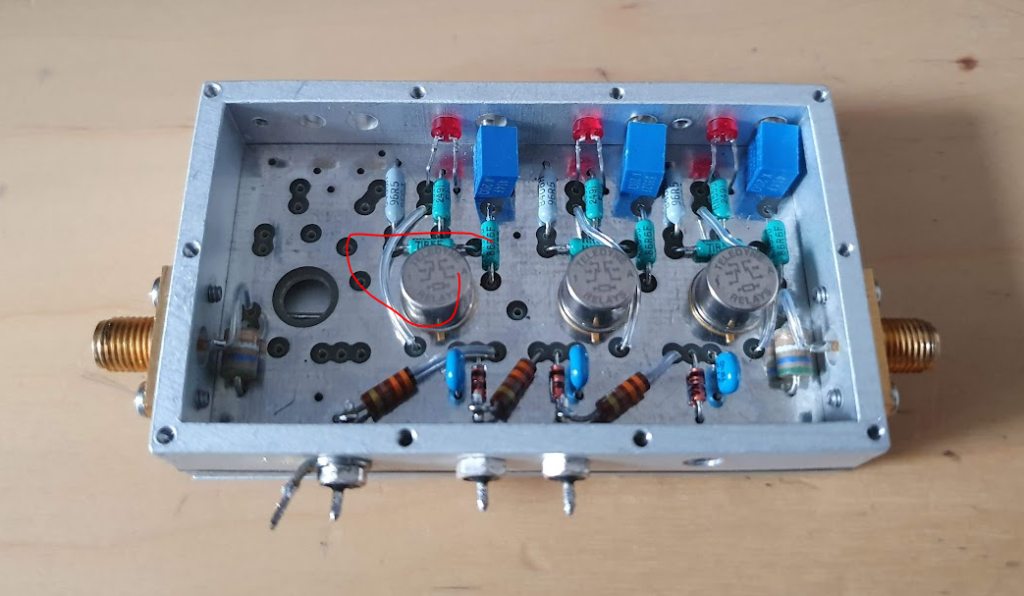

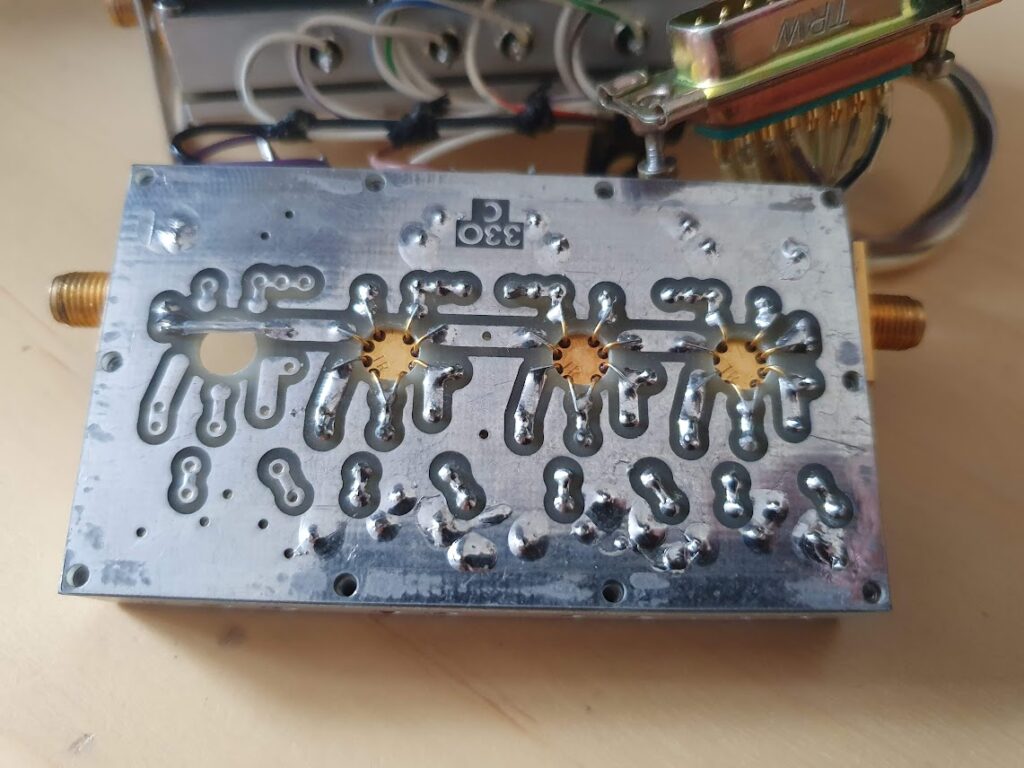

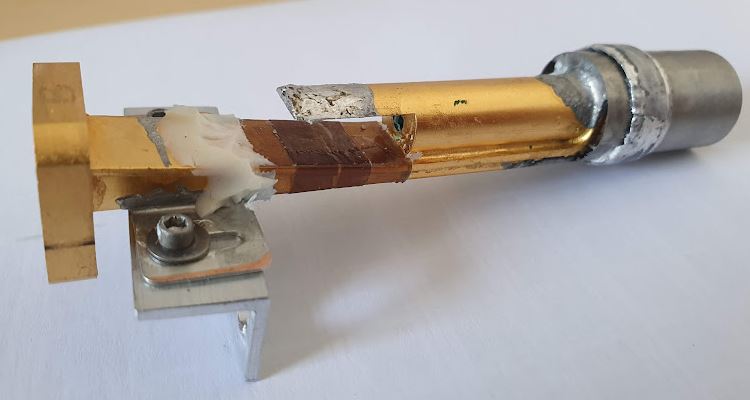

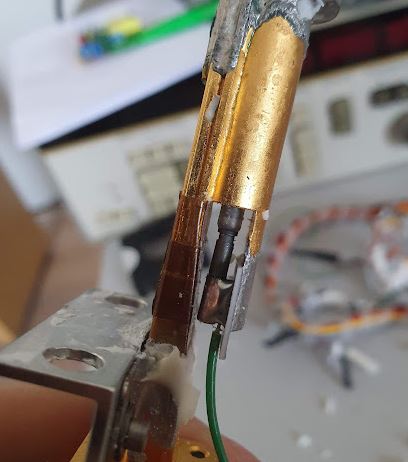

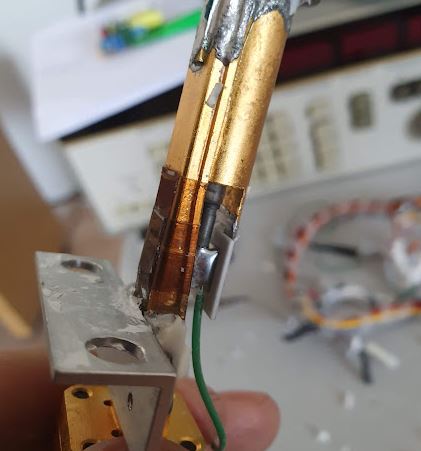

After calibrating all the oscillator frequencies, which went without trouble, I noticed that the top 120 dB attenuator was 0.04 dB off, well, not a big deviation, but I would rather have the unit working perfectly. So I removed the attenuator for further study.

It is build with really high quality relais, more than USD 50 (each!!), and some precision resistors.

Nothing could be found wrong with the unit by visual inspection.

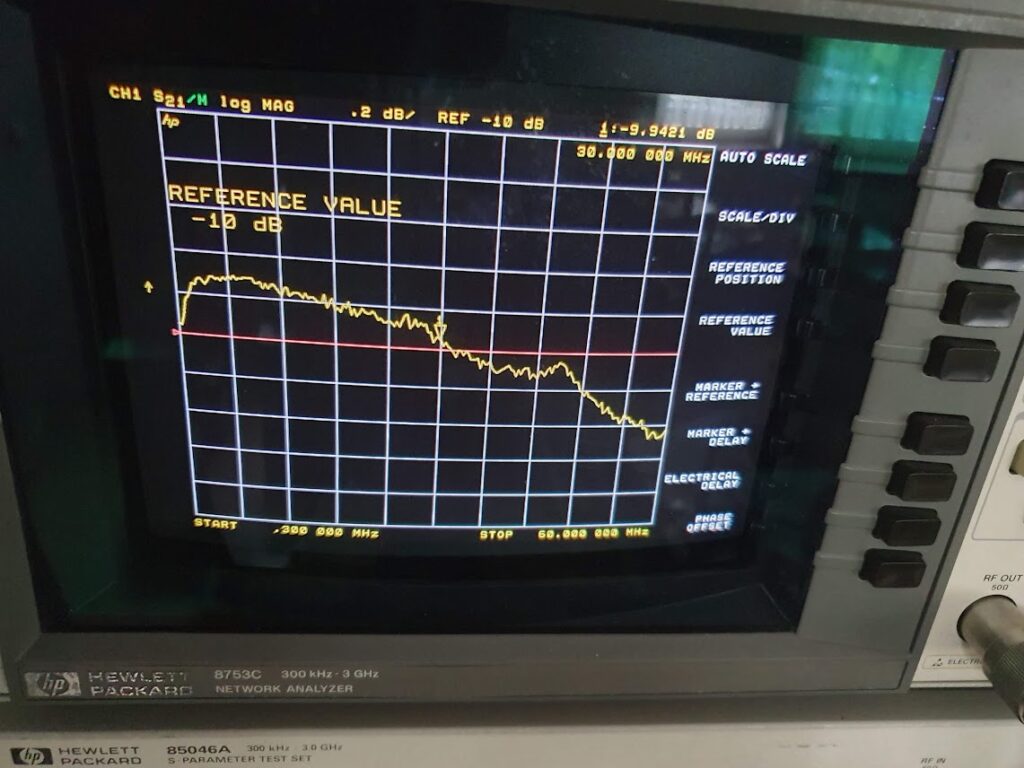

Also I used the VNA to check the attenuator, and all seems well working.

All the 3 segments, virtually equal at 10 dB each.

Finally, I put everything back together, a little clueless, but, now, for some reason, all is working and stable. Maybe it was some lose connector, or other strange effect that is now gone. All attenuators calibrated perfectly, using by HP 3335A level generator (which has a top-accuracy attenuator).

Finally the 1295, working just perfectly fine. Maybe better than ever before.

Interestingly, as with all of these Micro-tel devices, the side and top/bottom panels were painted with various kinds of special military paint – some with a rubberized paint that will dissolve into some gluey substance over time, some with a type of “abrasive” paint, other already re-painted in forest green.

The paint has very large and hard grit, almost like sandpaper. But I will leave it untouched, it seems the original looks for this serial number range (the 1295 seems to have been in production for 10+ years).

Now, a little gallery of all my Micro-tel 1295 receivers: the first two, part of my frequency-locked attenuator calibrator (can measure reflection and transmission at the same time).

One as part of an E-band (60-90 GHz down-converter).

Any now, already two spare units in perfect calibration.

Still, in the basement, a box of spares… likely I won’t run short of receivers soon. Maybe even buy another one should it come around.