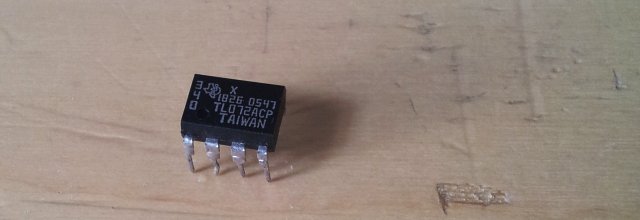

A broken noise figure meter, not really a good situation with so many tasks related to noise figures at hand, not only the noise source projects. So, another look at the A7 assembly. With the suspect TL072 opamp replaced by a less suitable, but known-working subsititute, the fault still comes and goes – well, maybe, in the end, the TL072 is not even at fault? There aren’t so many components around, so I checked for all the likely and unlikely things, and found – a defective integrating capacitor!

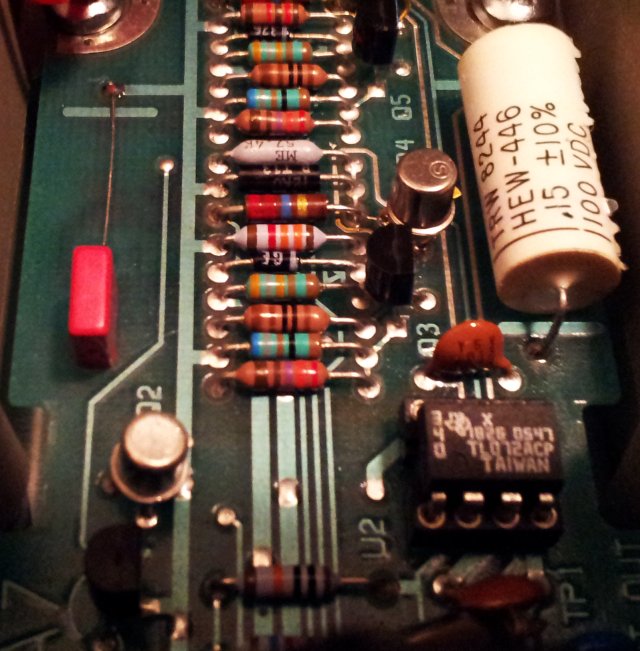

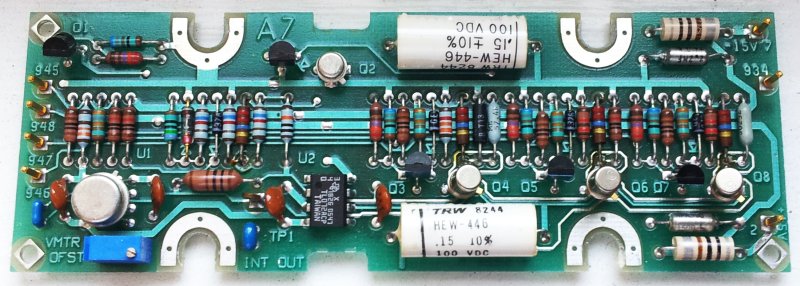

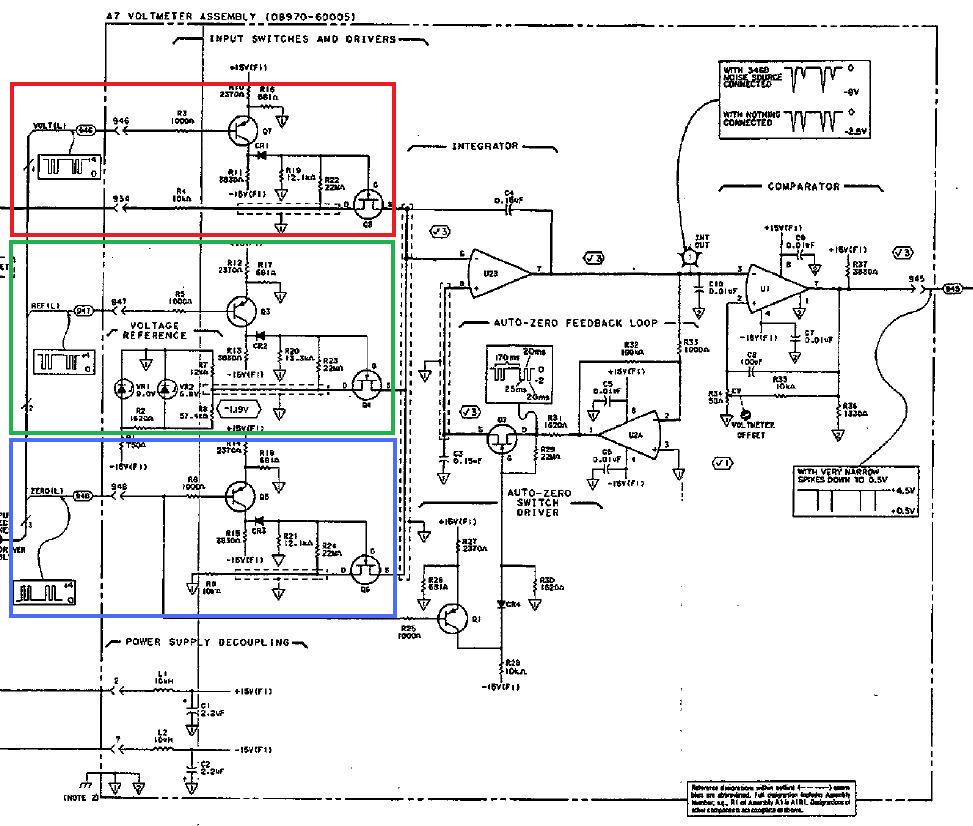

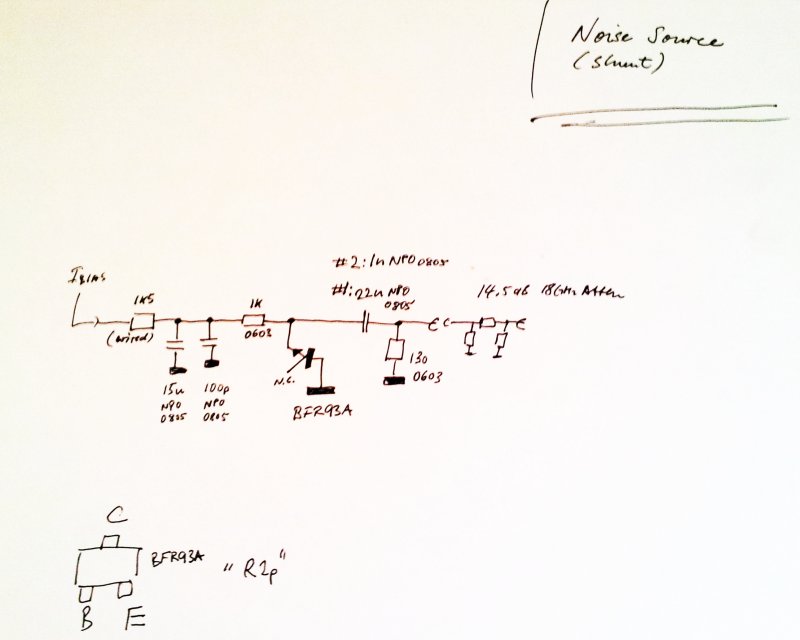

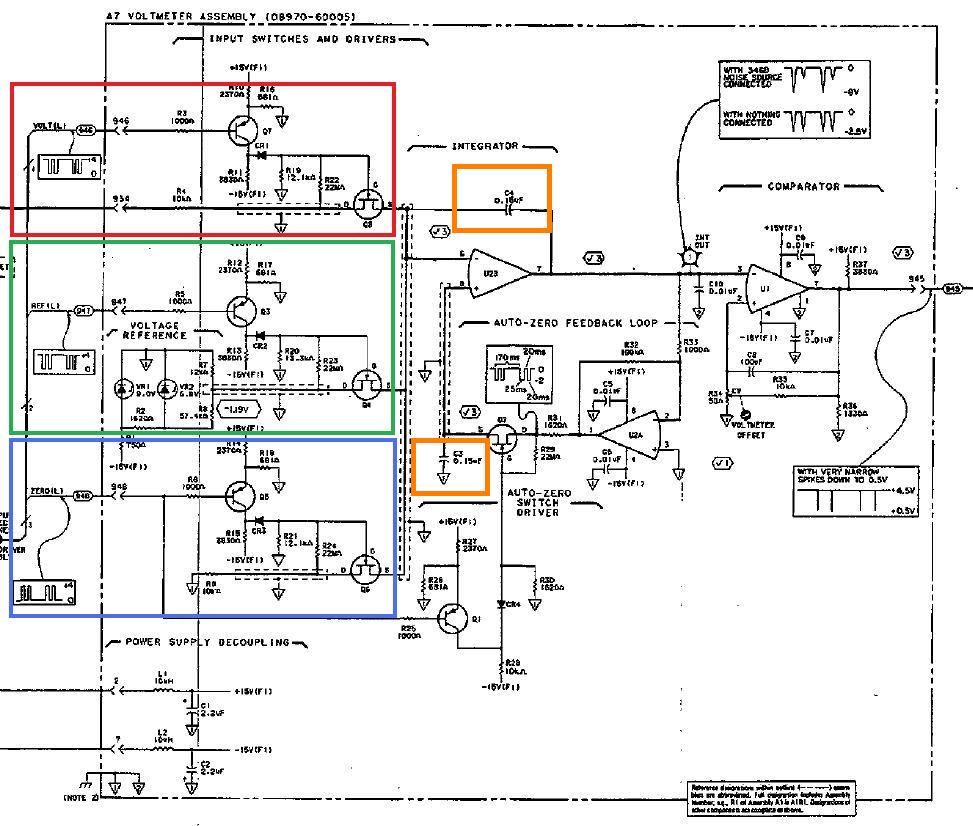

See the schematic – there are two of the same kind – C4 is the bad one (integrator cap; upper orange frame), C3 (auto-zero; lower orange frame) is fine.

0.15 µF, 100 V, Mylar, 1982 vintage, and after all these years, somehow, it has developed an intermittent fault (the first Mylar cap with such fault I have ever seen).

With no spare at hand in my tiny New Jersey workshop, I decided to swap the caps, using C3 as C4, and temporary mounted a 0.1 µF film capacitor (Wima FKM) as C3. For the auto-zero function, the exact value and leakage of the capacitor won’t matter so much, anyway.

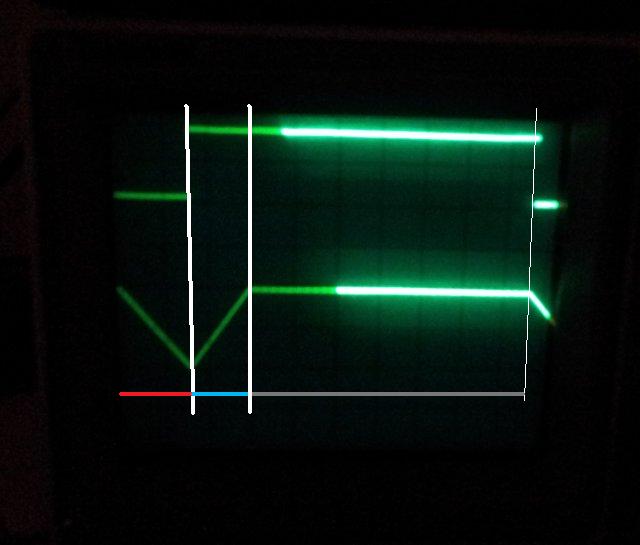

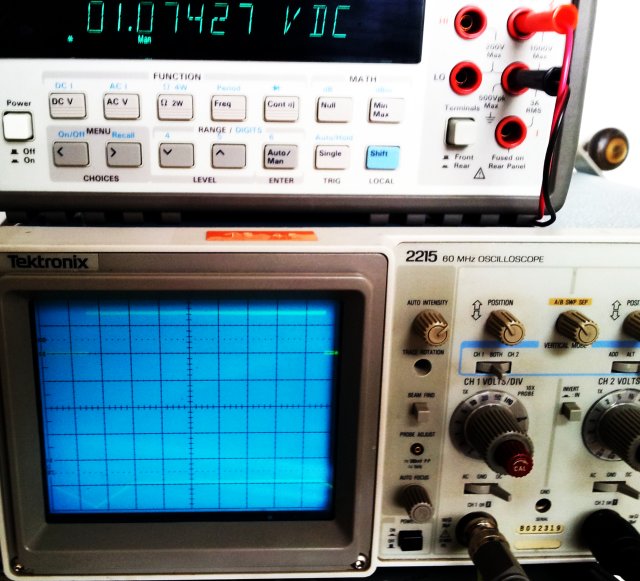

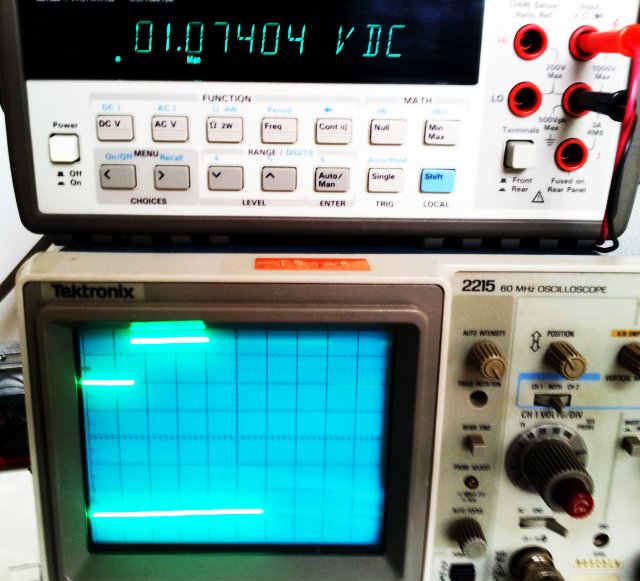

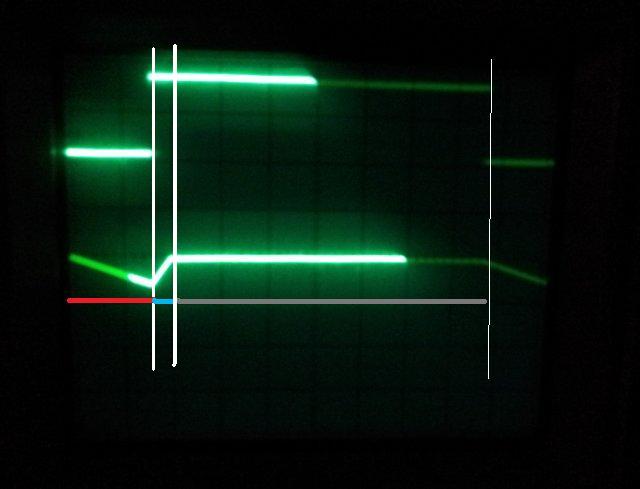

See, how nicely it works: red – integrator charged from input voltage; blue – integrator discharged by reference voltage; grey – auto-zero; this sequence repeats over and and over again, and the duration of the reference segment is determined, after applying the input voltage for a fixed time (all controlled by LS TTL logic on another board).

0.25 V input, 1.2 V reference.

Some quick thoughts about the capacitor; typically, Mylar/PET/polyester caps aren’t the best for integrators, because of higher leakage current, and dielectric absorption, compared to, say, polypropylene caps. Maybe, at the time, HP engineers determined that the TL072 leakage current, and other leakage currents on the board would be much larger than any capacitor leakage current; or, they didn’t want to introduce specialized parts – these axial Mylar capacitors of TRW brand were quite common in 1970- early 1990 era HP gear. These are actually not metallized Mylar/PET, but film-foil capacitors (using discrete plastic and metal foil, similar to Wima FKS-3).

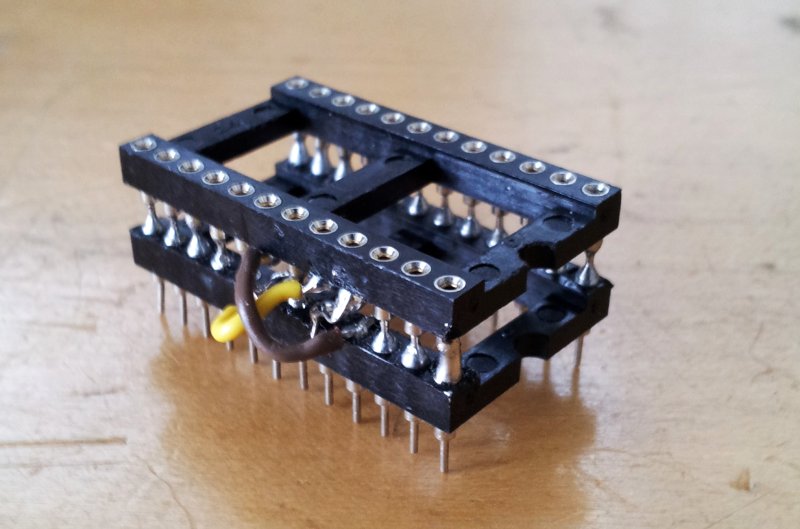

Look inside the dead cap – there actually are the plastic and metal foils.

For the next few weeks, this configuration will be sufficient; then I will check capacitor stock back at the main workshop; most likely there are some Wima/Epcos/TDK FPK or MKP (PP dielectric foil-foil or metallized PP foil) capacitors around; if not, then I will just fit a pair of good Mylar caps.