With the workshop basic repairs complete, how to set up a cost-effective lighting system?

Some items to consider

-I will be working there mostly after work, late in the evening, and mostly in the dark winter months. So I need daylight and bright light to keep focus.

-Diffuse light along will not be enough. I like the feeling of incandescent lights, so there need to be some work and bright direct lights.

-Some areas, like the stair, will need a separate light, which needs to be “ON” immediately after the switch is pushed. Same applies to the other lights – there should be no dimm start-up, flicker, or start-up delay.

-Light level needs to be high, because the main purpose of this room is the assemble, fix, and test high frequency/microwave assemblies, and fine-mechanical devices.

-Because this is a hobby, we need to keep expenses down, both for the initial cost (light fitting and lamps), and the running cost – electric power cost.

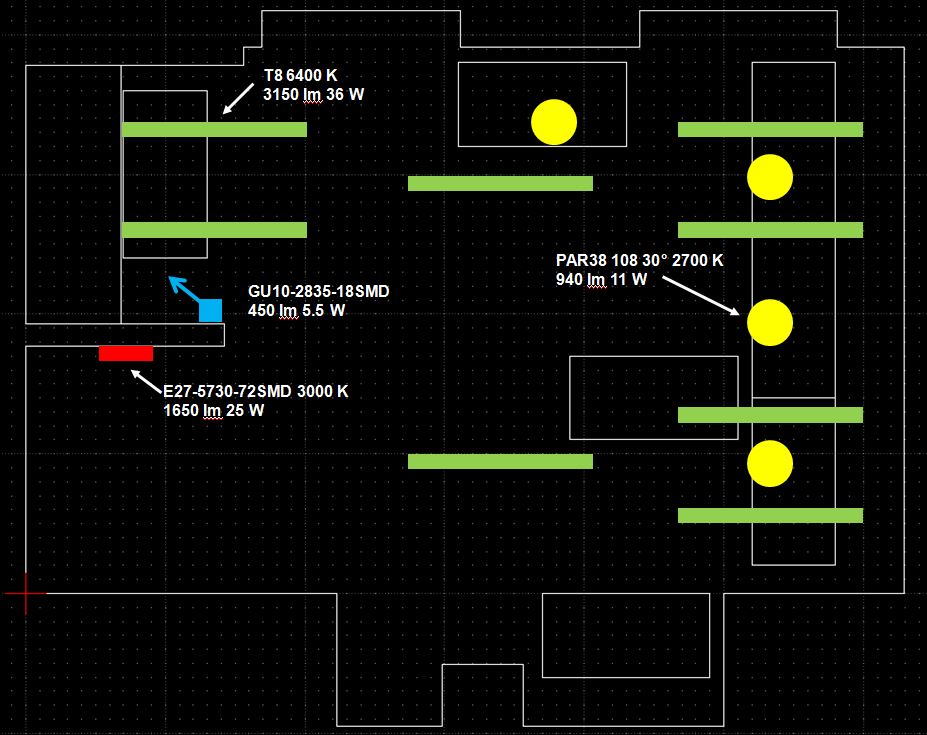

This is a plan of the room layout, rectangles mark the position of tables.

Essentially, two kinds of light sources have been considered – T8 fluorescent, for the background illumination, 8 pcs. 25200 lm total (EUR 5 per piece, including lamp and electronic started – a bargain). And 4 PAR38 30° LED down-spots (these replace the 108 W halogen lights, and have still have a nice glass body).

These are about EUR 13 per piece, and the light fittings are simple screw sockets E27 size, EUR 1.50 per piece.

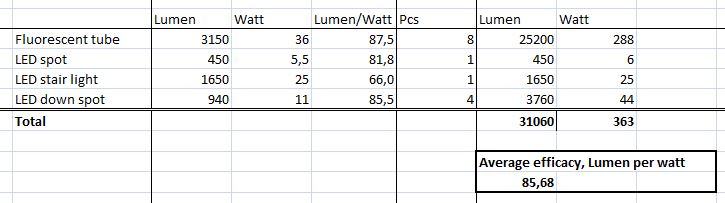

Some calculations done – total of 31 kilo-lm, 363 Watts (which is quite precisely found when checking the total current to the workshop with a wattmeter). ~85 Lumen per Watt, which is a very good value.

We will need to check the actual luminous intensity at the work surfaces later, because the lumens of the fluorescent tubes is not all going downwards (some reflected from the white ceiling and walls, some lost in the light fitting).

Life time these lights are rated for 25000 hours (LED), or 12000 hours (T8 tubes). This means, 3000~6000 hobby days (counted at 4 hours), so there should be no need to change these light bulbs and tubes any time soon.