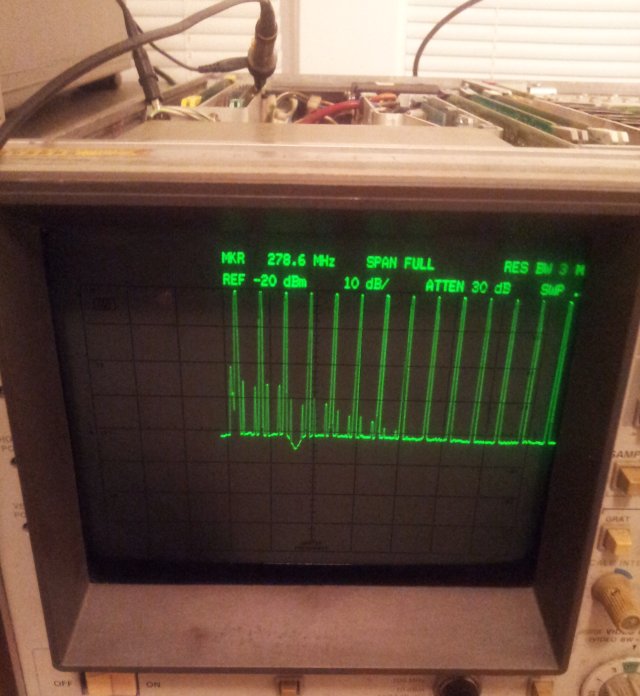

There are a few remaining items that need to be fixed:

(1) The frequency marker doesn’t work

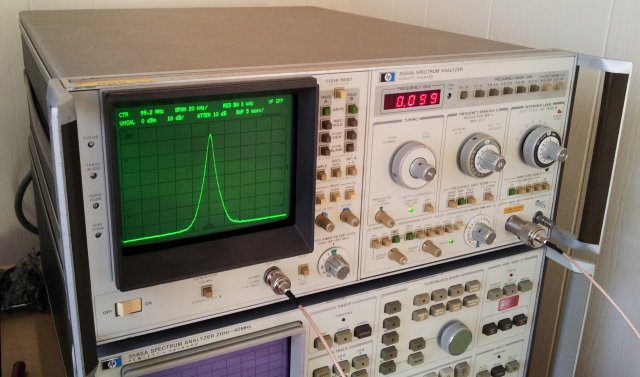

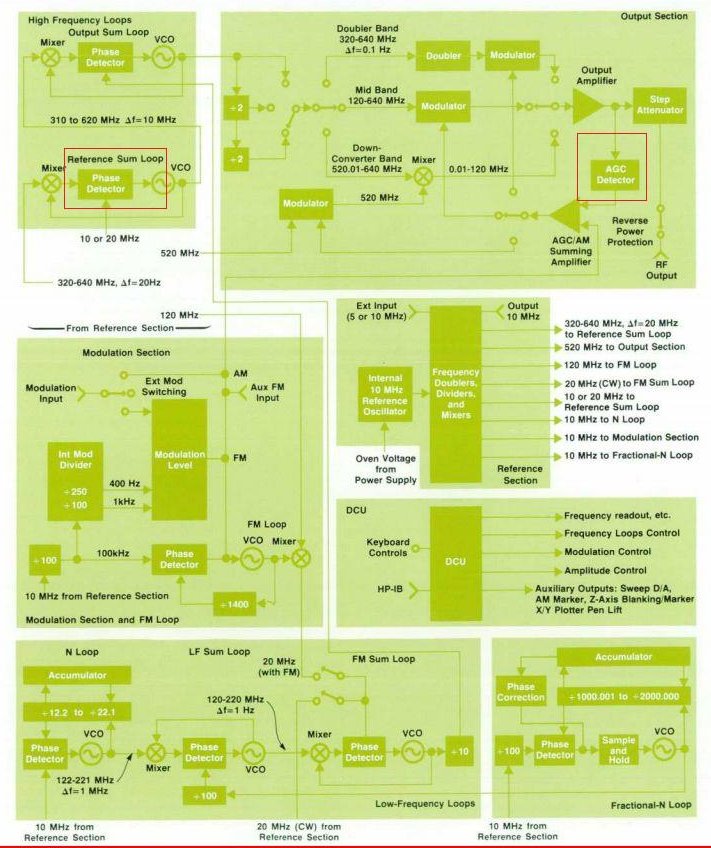

(2) The AGC circuit is acting up a bit

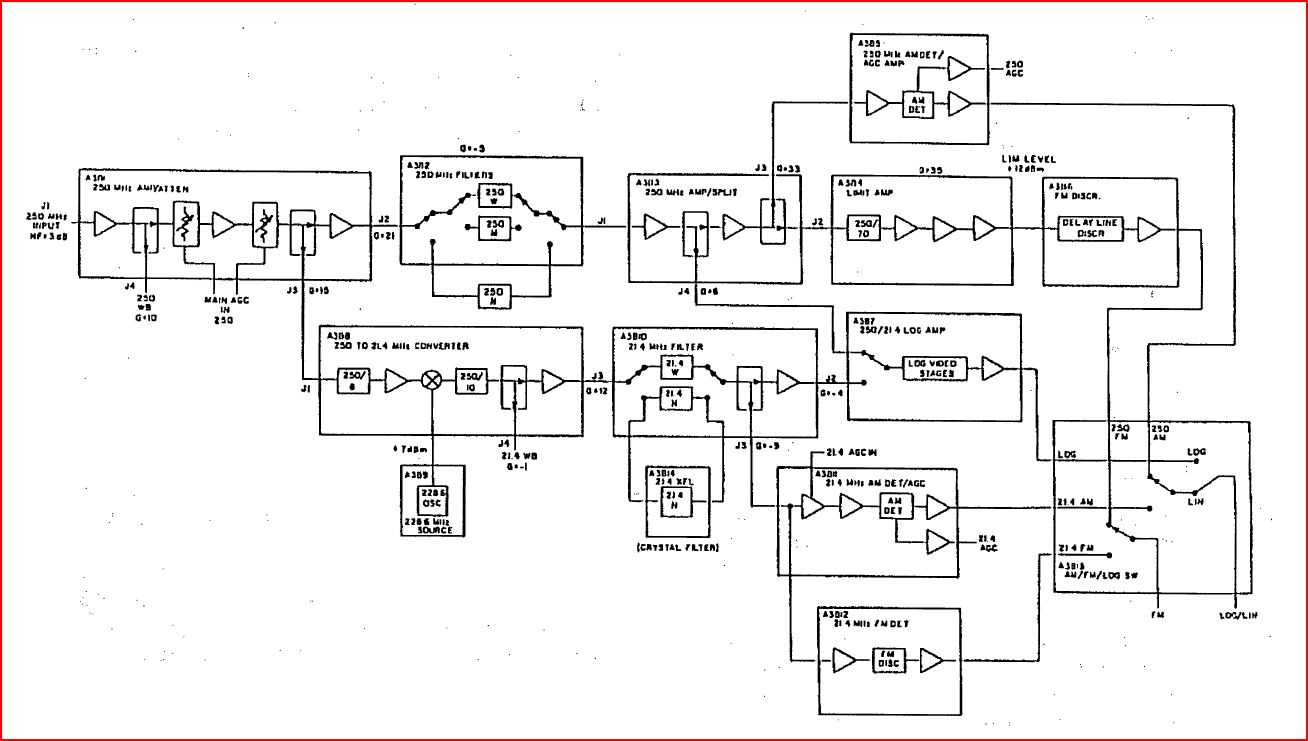

(3) The 21.4 MHz IF chain – it is working but gain seems low

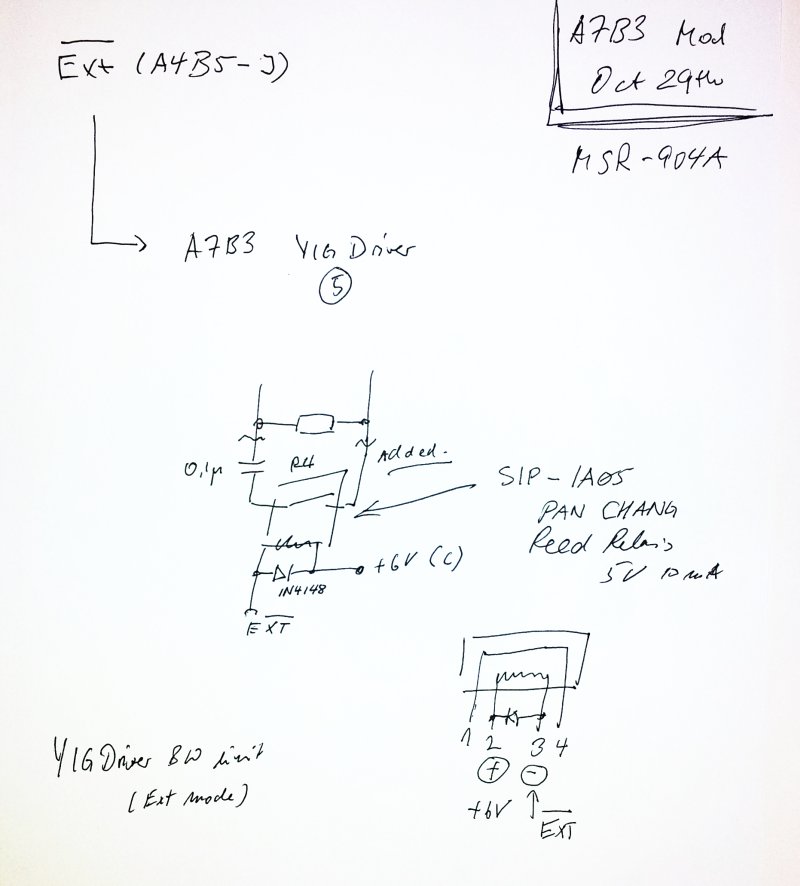

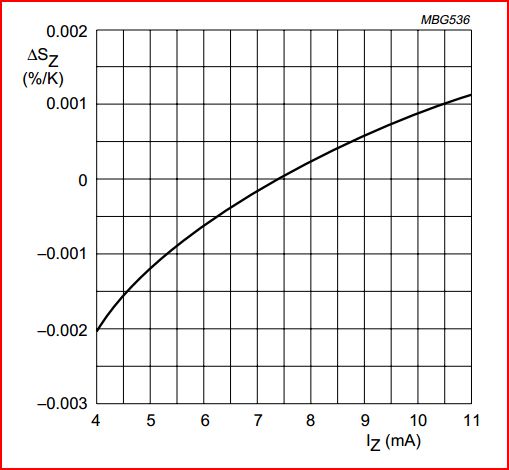

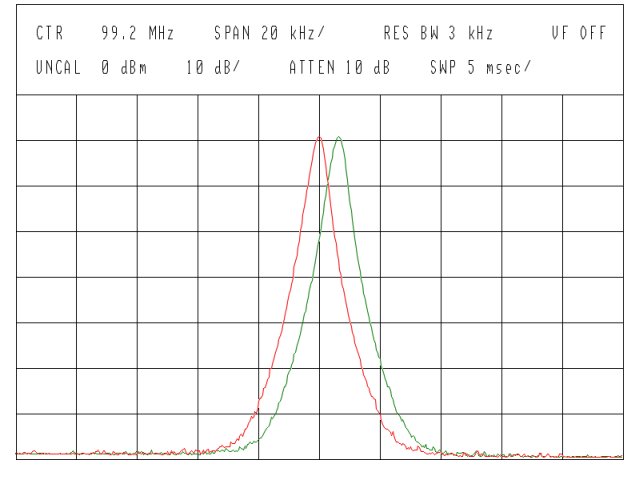

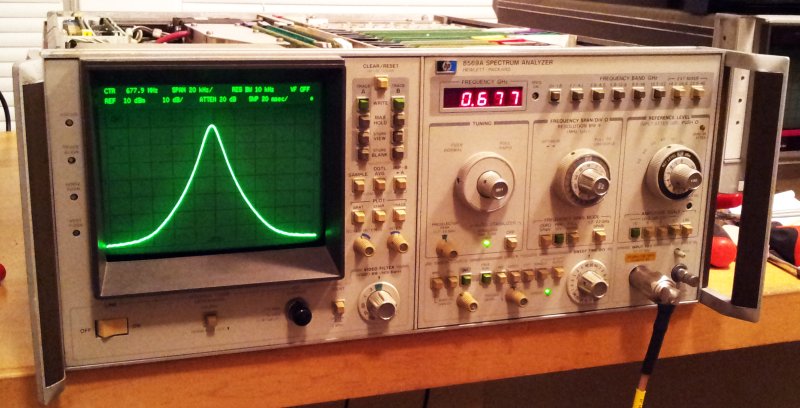

(4) The YIG driver – it has too much inherent noise when using the external input (EXT frequency mode). Added a 100 n capacitor (see earlier post) – but this interfers very much with the faster sweep rates, where full YIG driver bandwidth is needed. So I need to add a switch that takes out the 100 n cap, except when in EXT mode (not planning on any super fast sweeps in EXT mode, but definitely need low phase noise)

(5) The ‘signal strength indicator’ is working (a nice LED bargraph), but the offset can’t be adjusted properly, and it moves eratically, at times.

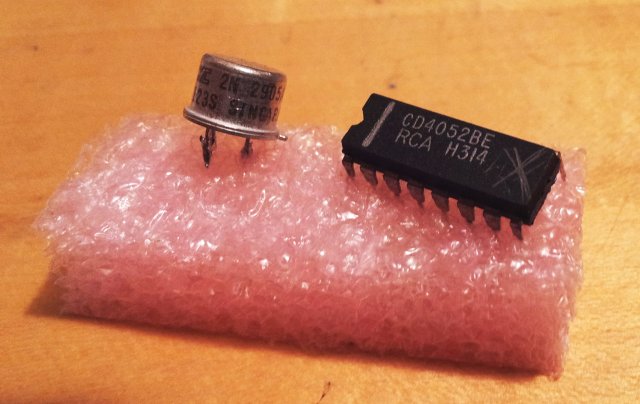

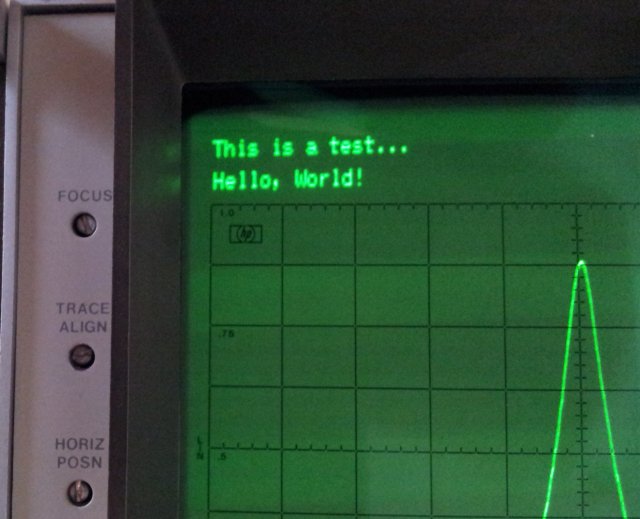

With the manual, the search defect (1) – marker that was so far difficult to track down has an end: the issue is one more of the CMOS switches, a 4052. Well, already the second of these switches which is bad. Maybe, I should just replace all the 4051, 4052 and 4053 switches of the units, as a matter of preventative maintenance. Well, we don’t want to fix things that ain’t broke.

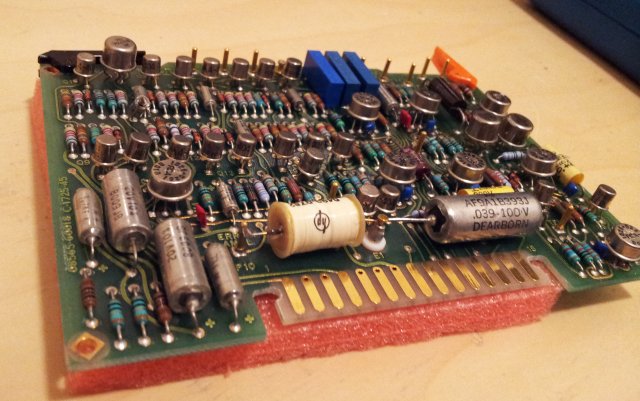

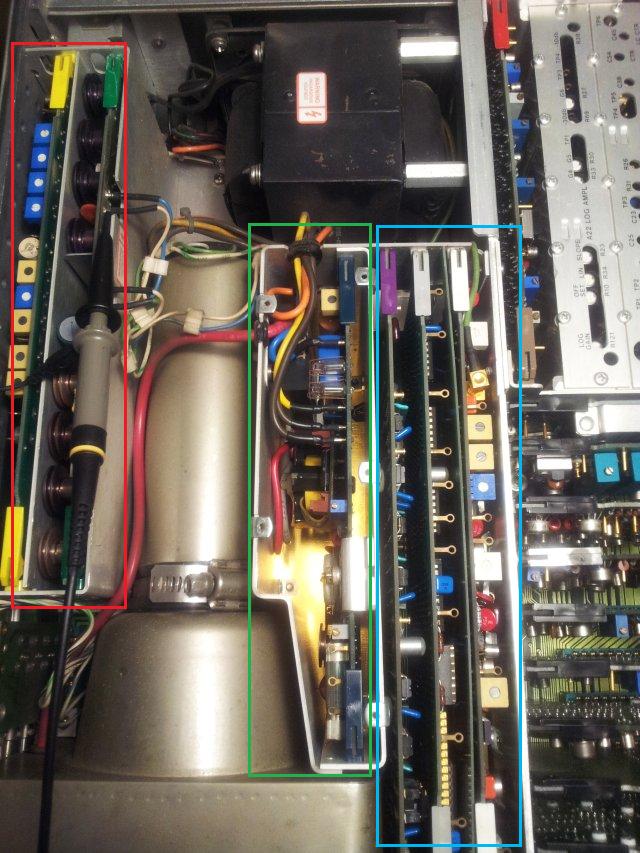

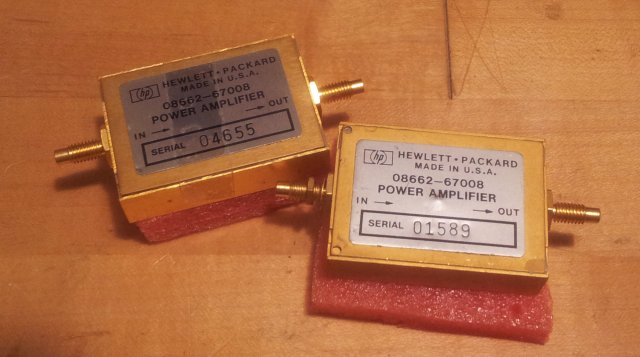

Item (3) – nothing worse that disassembling the IF chain – by all admiration for this unit, the 2nd IF chain is not build for troubleshooting. But, following the instructions, first a check of the control assembly. And, quite to my surprise – a defective transistor switch, using a 2N2905 PNP transistor that provides +15 V power to one of the 24.1 MHz amplifiers – this is switched on and off depending on the BAND setting. The transistor – only had a 2N2904 around, same kind, but a bit lower gain. Well, it works – need to check stock back home in Germany when I get a chance.

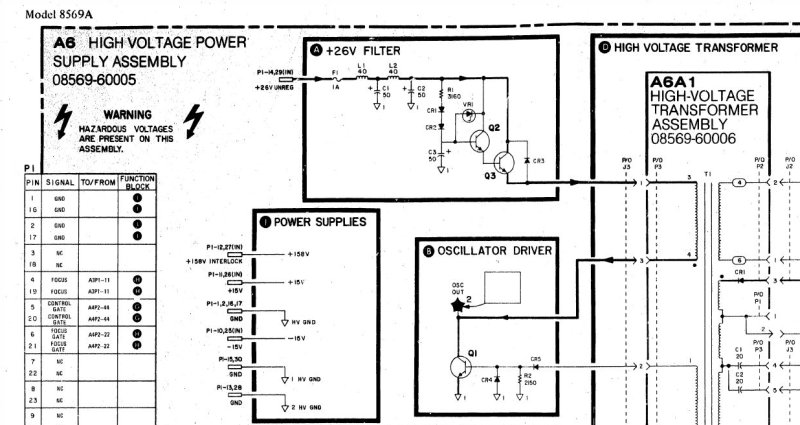

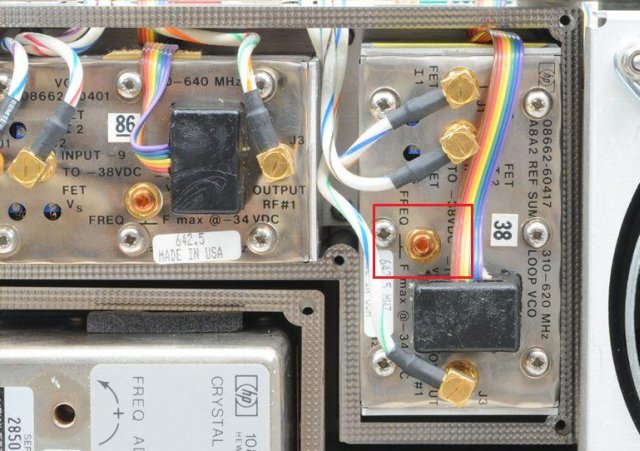

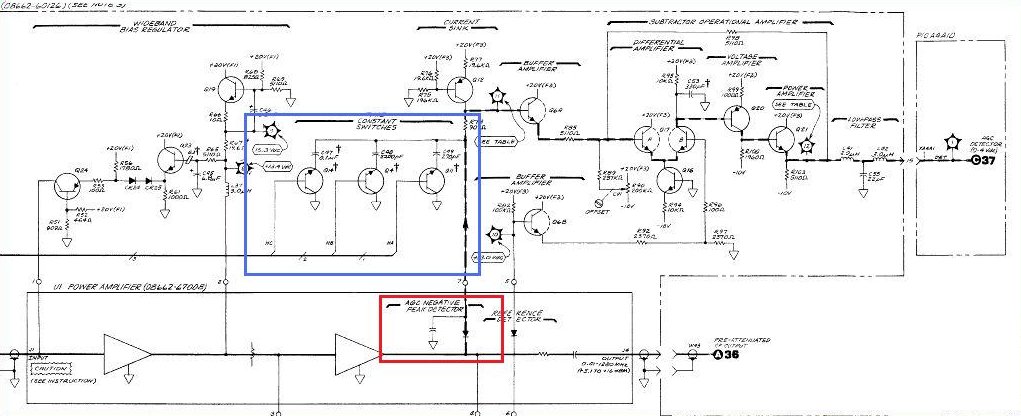

Item (2) – this was “just” a matter of adjustment. Adjustment isn’t all that straightforward – and the manual doesn’t cover everything. Needed to peak the 250 MHz amp/AM detector circuit – there is a tuned amplifier inside, which has and adjustment capacitor not described in the adjustment instructions – fortunately, pretty clear from the schematic.

Item (5) – turned out to be a 1458 opamp not working properly, replaced. Pretty easy – most of the integrated circuits are in sockets. Sorry, no picture of the defective 1458 😉

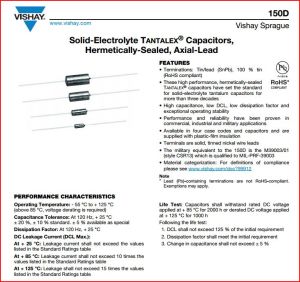

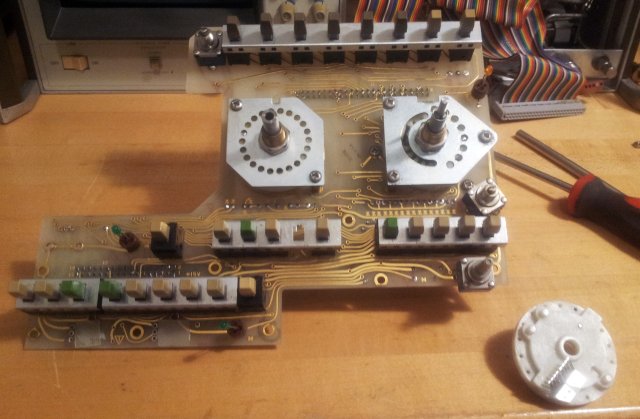

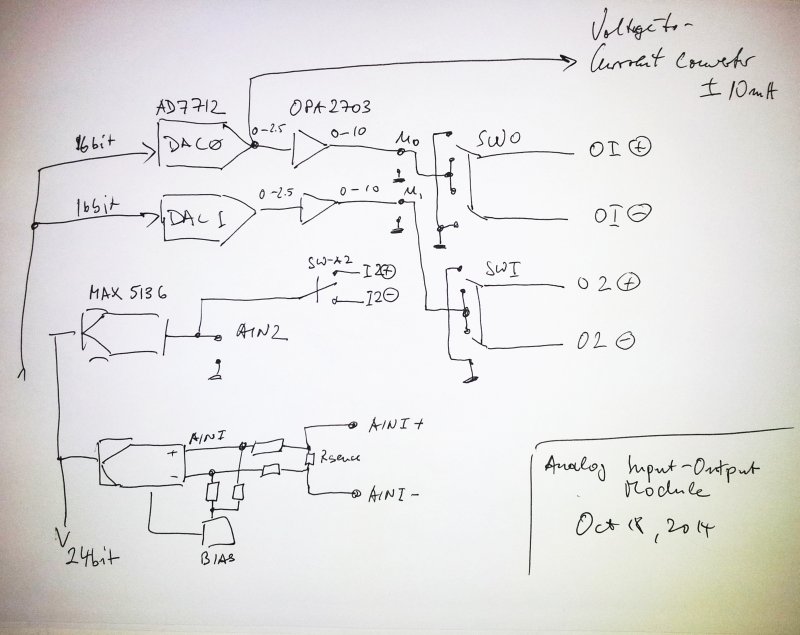

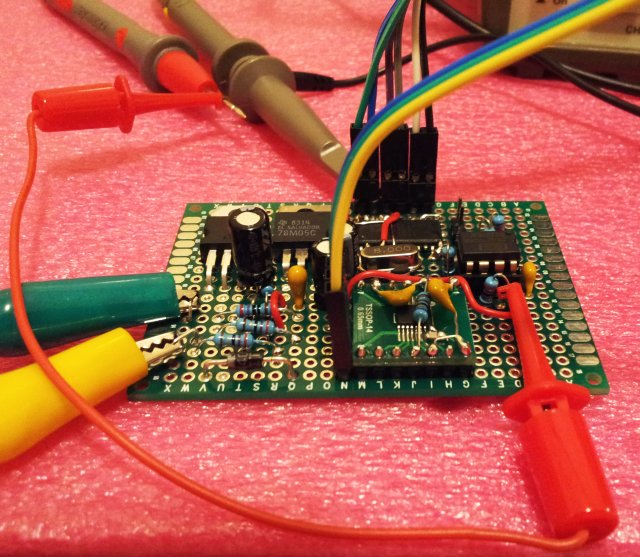

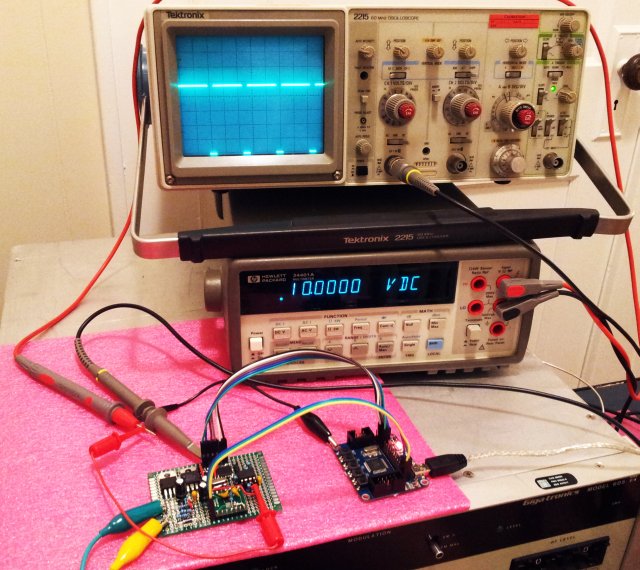

Item (4) – added a good Chinese brand SIP reed relay, PAN CHANG SIP-1A05:

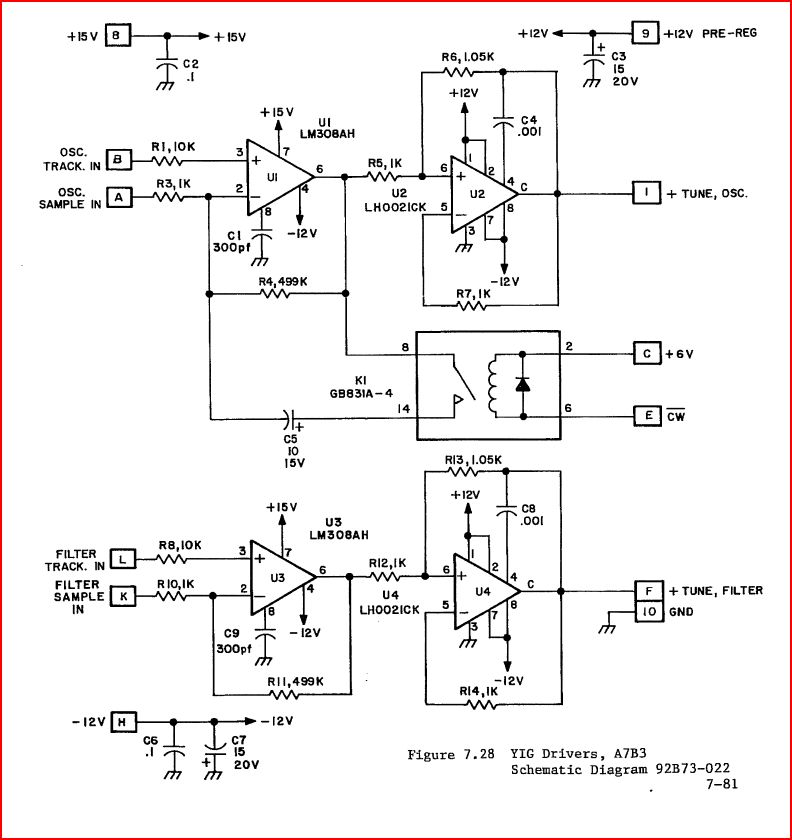

Routed a wire with the EXT signal (low when activated) to the YIG driver board. This is now taking the 100 n cap out of the circuit, unless the EXT mode is active. Added a protection diode, to avoid voltage spikes damaging the TTL circuit driving the reed relay.

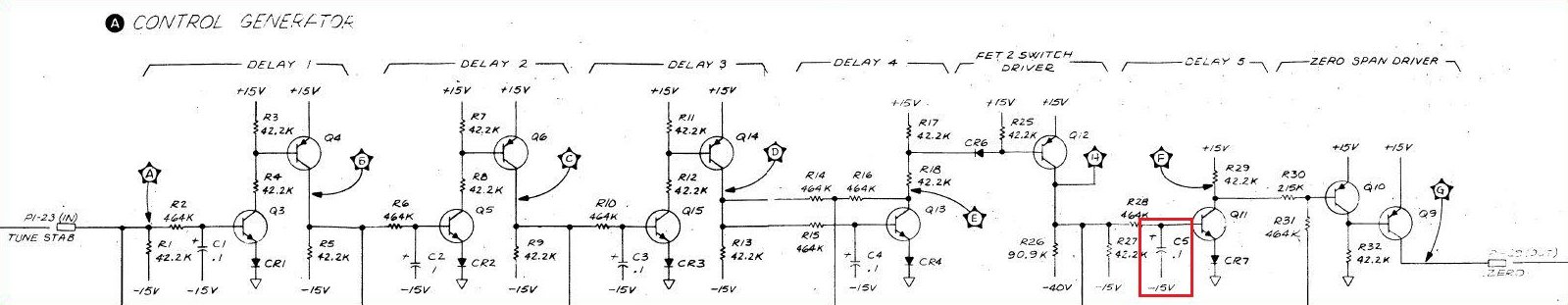

The 100 n cap and reed relay is installed parallel to the R4 resistor – same as for the C5 capacitor, which is activated in CW mode.