The 8645A – see earlier post, reached my workshop in a really bad shape, electronically dead, and severely damaged. For any reasonable effort, damaged beyond repair.

However, I do this for a hobby and there is no rush, and I just can’t take this thing apart for scrap metal – the case suffered damage, but the inner parts, no major mechanical issue.

For most of their 1980-1995 equipment, HP used a so-called “System 2” modular case, mainly, die-cast aluminum alloy. The 8645A is not much different – the bottom and top lid are different (to provide better shielding than the regular System 2), but the front frame, it is the same.

Looking around at xbay – found a complete front system 2 front assembly, System 2, from a 8782B Vector Signal Generator. The Chinese vendor, he seems to make a cut by taking apart equipment, and selling it for parts – it wasn’t quite cheap, but still, for a 8645A, to get it back into service, it seems pretty much worthwhile.

It arrived already after about one week.

Not in best shape, but usable.

This assembly also has quite a few BNC connectors, and a precision N connector, all very handy to fix the replace the snapped-off parts.

As it turns out, the N connector is of a different length, but never mind, I have some more spares around.

The front panel assembly, it is apparently one of the weak points of the 864x series.

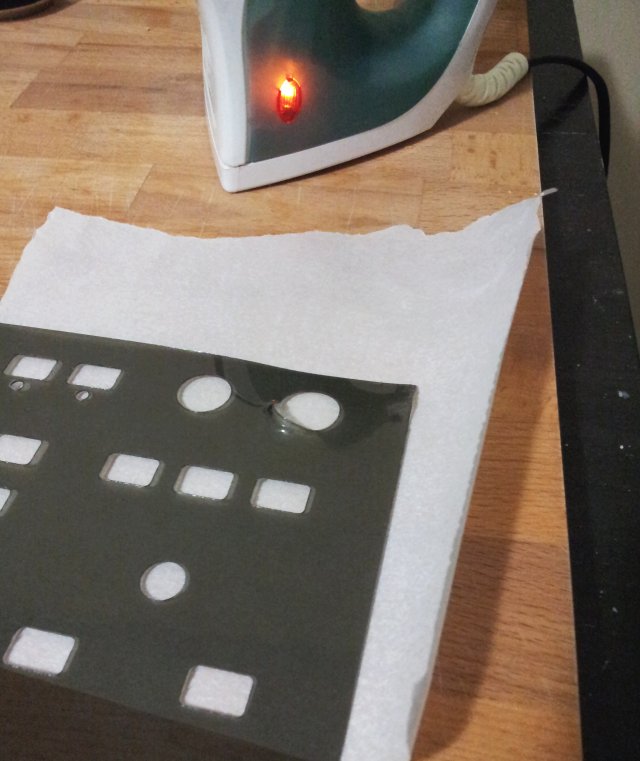

Two layers of rather soft aluminum, a ~0.8 m plastic sheet that also acts as filters for the fluorescent displays, and a thin outer layer with the labels.

This is quite easily pushed in, if force is put on the BNC connectors – it is always best to safely secure the instrument at the corners during transport, and to attach handles.

The layers are held together by glue, and it seems, HP has used a very sticky, but not permanent type – with great care, it can be separated. Key thing is to keep the sticky surfaces clean, and they are best protected by a polyethylene foil.

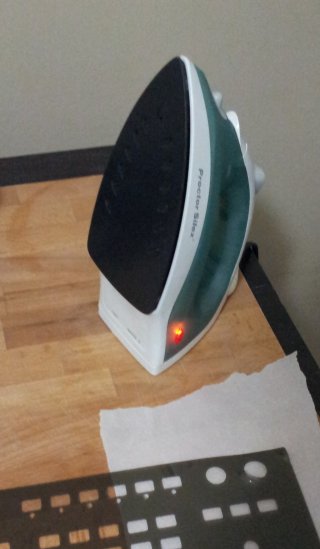

To flatten things out, a carefully adjust iron is a handy tool – with the plastic sheets put in between two layers of non-stick paper.

The more laborious part – the flattening of the aluminum panels, with a hammer, and a piece of wood, and about 2 hours of work.

The result – all things glued back together, pretty happy with the result.

Sure, there are some little blemishes, well, fair enough!

Now we just need to get the inner workings going…..