Most important for a well is the nature for the water-bearing layer. Already when using the soil drill I noticed coarse sand when hitting the water layer, and it is so liquid that it can be easily washed down and has almost no turbidity. This is basically a good finding, intermediately coarse sand, with little fines.

The top layer had a few larger stone, but in the water bearing layer, the largest were maybe about 8 mm in diameter.

Interestingly enough, the was a solid but -fortunately- thin layer of sand solidified by white matter in about 3 meter depth (just about 1 cm thick layer). Maybe the river running here over my land dried up some 1000s of year ago?

To color of the sand is somewhat red, but this color doesn’t wash out. Diffing further, from about 6 meters down, gray to black sand appeared. This sand was considerably finer and pretty difficult to remove by plunsching, so I used plenty of water and many strokes of a gravel pump to remove it (I modified the plunscher to a gravel pump by adding a piston – will be described in another post).

Finally, at about 7.5 m down, the sand turned more and more black with some brownish clay fragments and plenty of mica (shiny particles).

Given the 0.3 mm slot width of the filter, about 1-2 mm sand would be quite ideal as a water bearing layer, so I was definitely happy to hit solid clay about 7.6 meters down, and sunk the lowest pipe some 10 cm into this clay layer. Note that the clay layer is really heavy pliable clay, it doesn’t seem to swell or dissolve in water easily. So I even decided not to further close the bottom of the well pipe, it seems soundly stuck and closed by the natural clay.

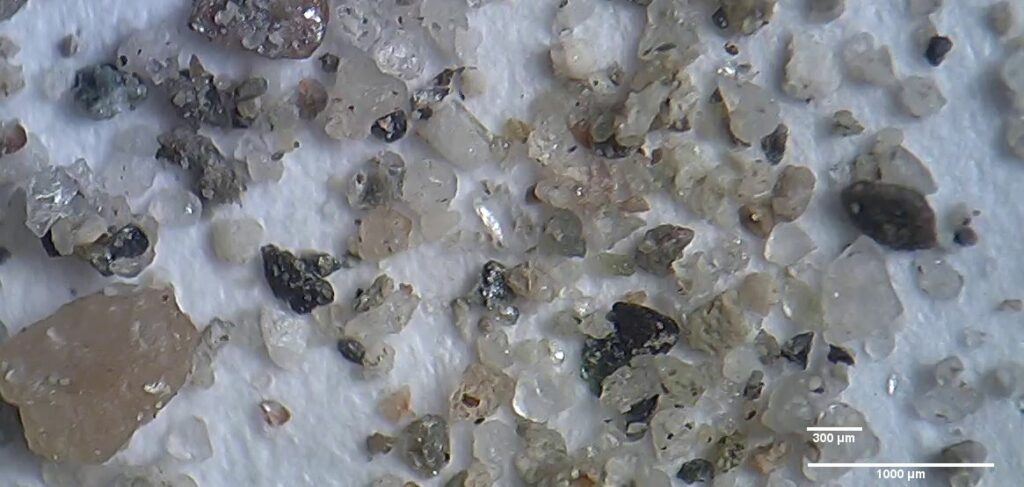

Some study of the sand revealed that the 7 meter sand has quite some sharp and irregular particles that can clog the filter, so better to keep the filter out of this area as much as possible. Maybe the lowest filter section (2 m in total) is now in the black sand layer for about 0.5 meters.

7 meter sand:

Even more important in such case to not overload the filter, to keep sand from getting into the well by keeping the inlet velocity at well below 0.03 m/s, better 0.02 m/s, which is possible by taking about 2000 L/h through the 2 meters of filter section.

The sand in the main water bearing layer is looking much better, it is coarser, and has more rounded shape.

Red marked are some small gravel, and the red lines show millimeter distances.

Main water bearing sand at about 5 meters, microscopic picture:

For thoroughly removing all sand from the well, I used a sand sucker construction from regular PE pipe (32 mm outer diameter), and a 8 mm pneumatic hose inserted such that it is pointing upwards, and extending about 15 cm inside of the pipe. With ample supply of pressurized air (from a compressor) connected, it will pump up a mixture of water and sand even to 8 meters, no problem. Sure it is a mess of water, sand and dirt, but it is an easy way to get rid of all the fine sand and mica that can’t be effectively removed by the gravel pump finally.

I also supplied plenty of water by a flushing tool, finally, also used this to soften the clay and to flush out a few cm of clay, but introducing a fairly high pressure (6 bars) water jet and pumping out the dirty water at the same time.

I continued to pump out water with the air-operated pump for about 1 hour, finally, I connected an old electric pump to the well for about 3 hour, and during all that time there was basically clean water after the first 30 minutes. And so far it doesn’t show any sand residues after one week of use, so maybe we are safe. Let’s check in one year! Surely I will keep all the tools so I can flush out any sand or residues in coming years should need be.

Hello Simon,

again, a barely scientific work now in pedology research. I always admire your broad area of interests and projects you realize and your way of publishing it in your own way. I like to read it very much!

Best regards from Prague,

Vojtech.