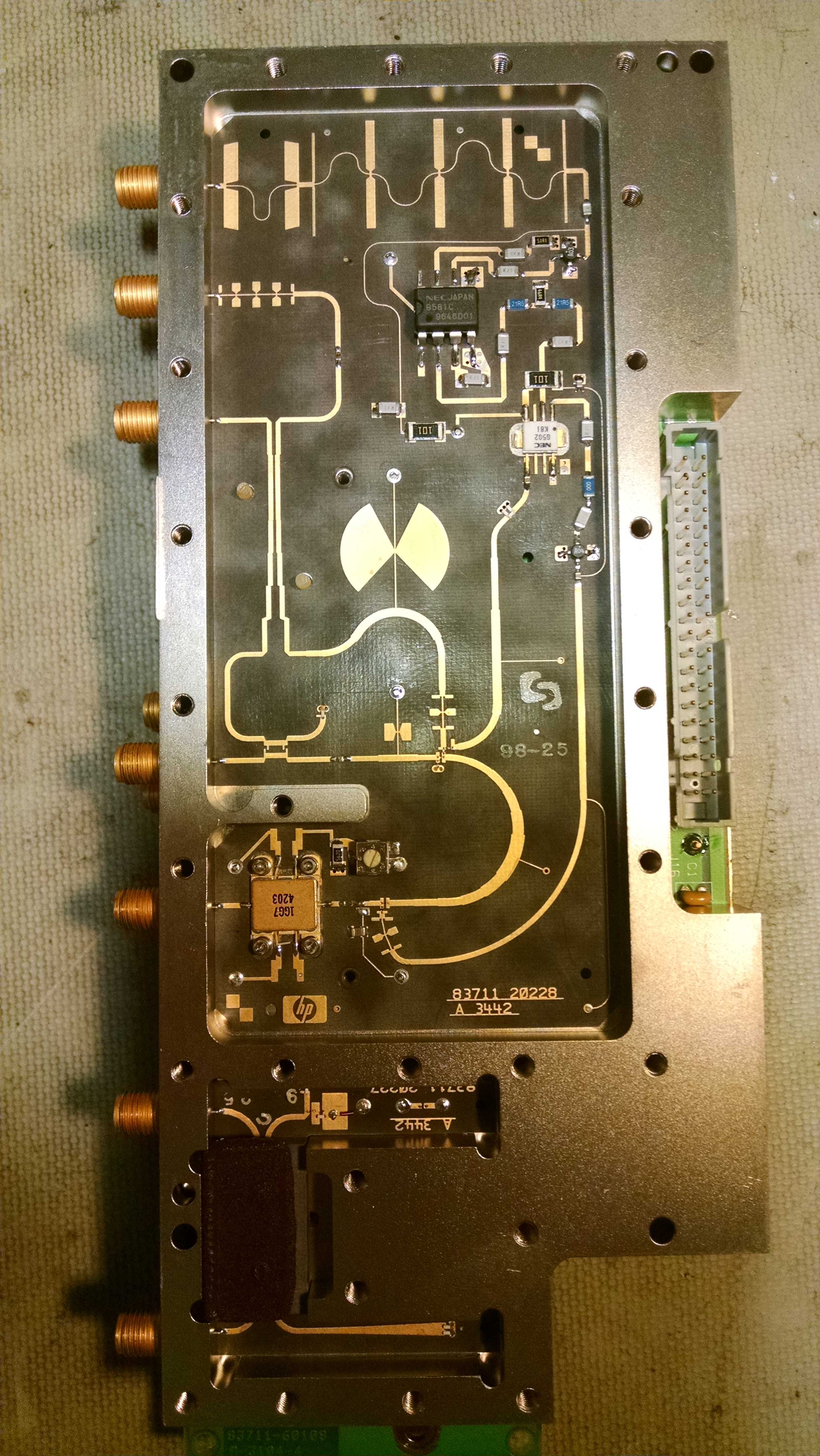

Several years ago, I managed to get hold of a rather special piece, an electromechanical master clock, including an Invar temperature compensated precision pendulum. Such clocks were use to control various remote clocks at a train station, in large factories, or huge governmental offices, etc.

These clocks have long been superseeded by crystal oscillators, nevertheless, they are marvelous pieces of precision engineering, and it has been a long held thought of mine to measure how accurately this time-piece is performing, not only long-term (which can be easily timed by daily checks), but also short time, for each individual tic.

The pendulum has a 1/2 period of 0.75 seconds, which is quite common for such kinds of electromechanical clocks. Only the most wealthy businesses opted for a 1 m (full) pendulum, and the instrument is large enough anyway even with 3/4 lenght.

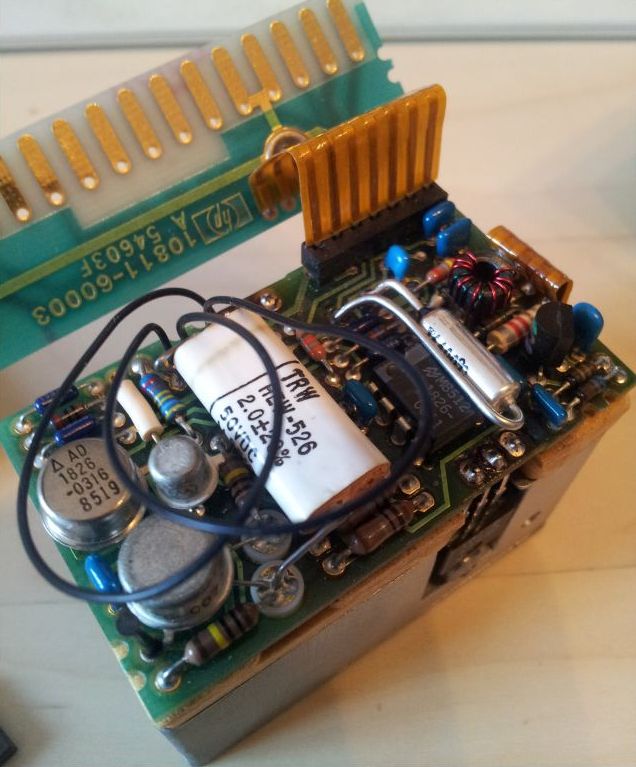

The dial is quite beautiful, and every piece appears to be hand-made. There is no date on the clock, but the age of the capacitor suggests 1920~1930 time-frame. I fully rebuild the mechanics about 3 years ago, all degreased, checked, and freshly lubricated with clock oil. There was no need for any other repair, all parts and bearings are still in good shape.

The clock has a rewind mechanism that is activated once per minute, and also turns a polarity reversal switch, used to steer the remote clocks.

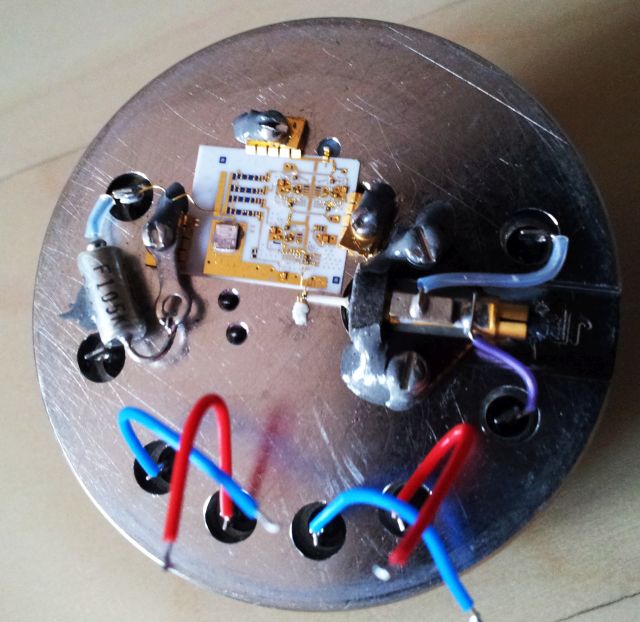

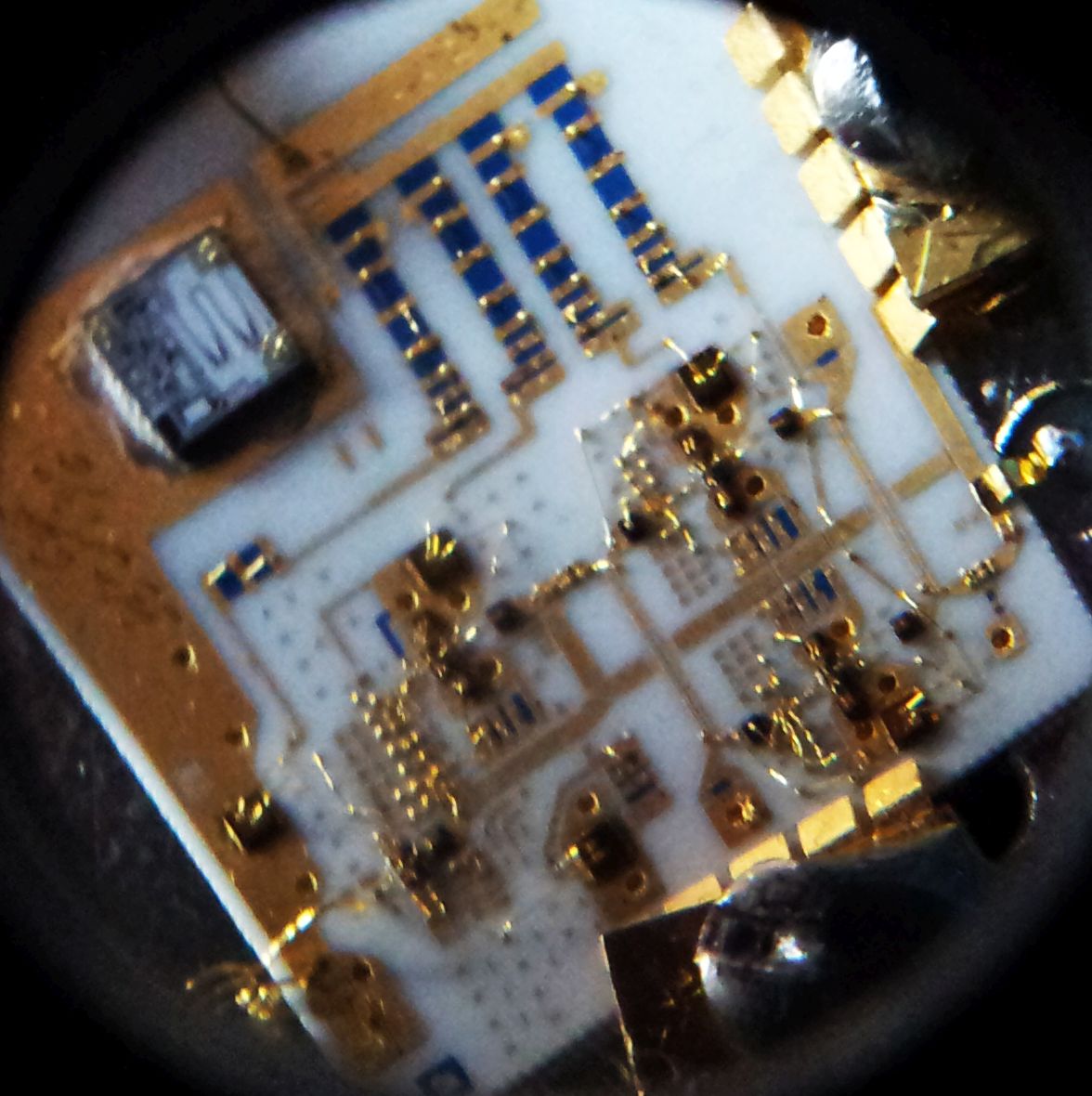

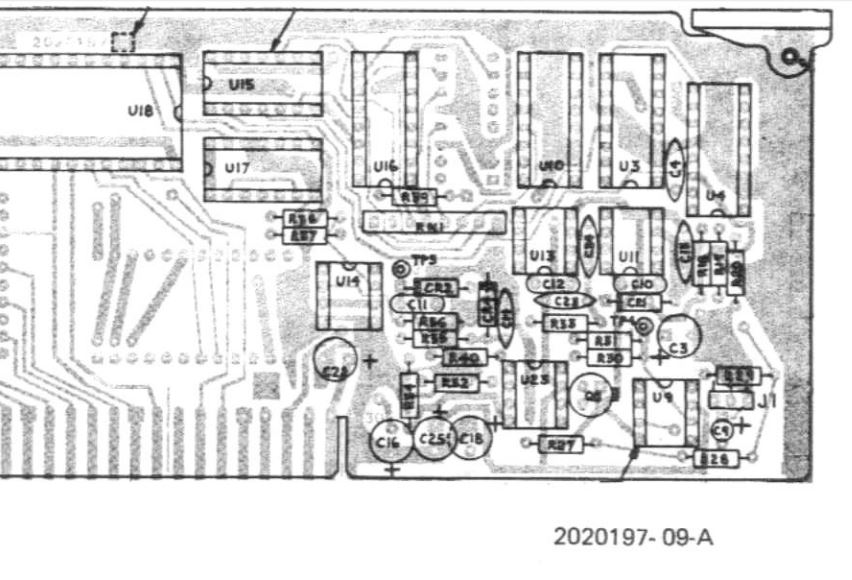

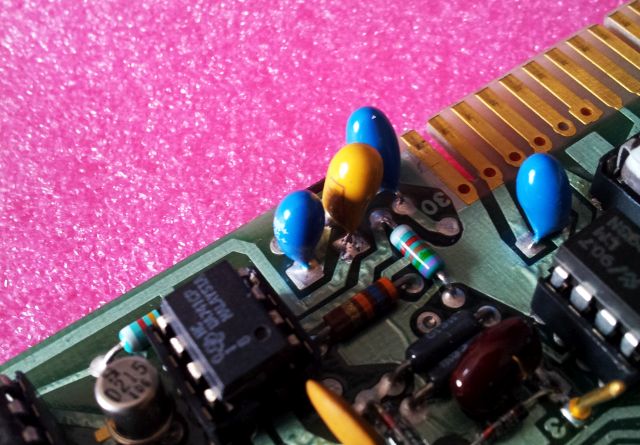

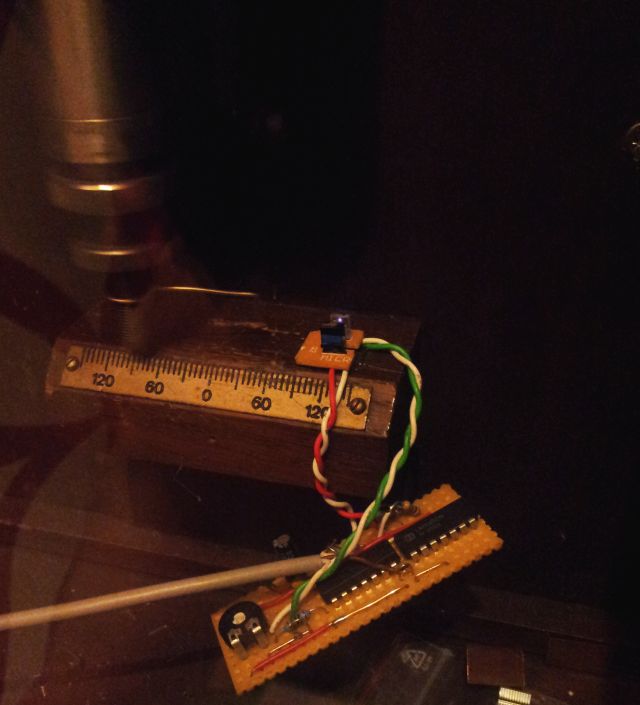

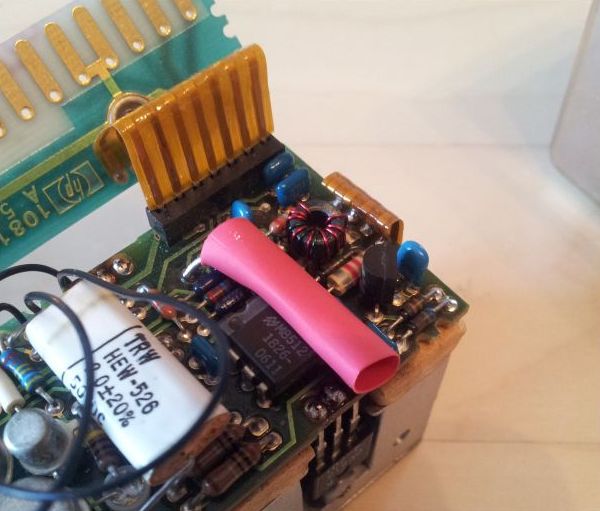

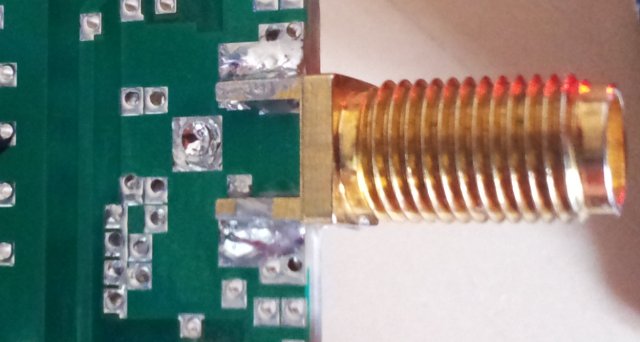

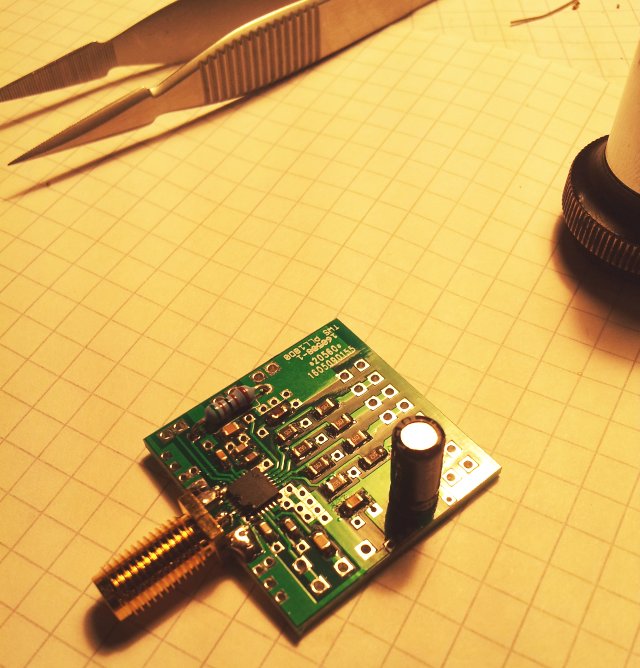

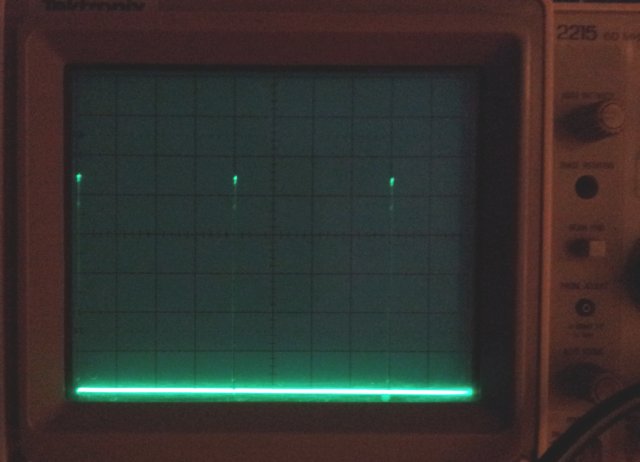

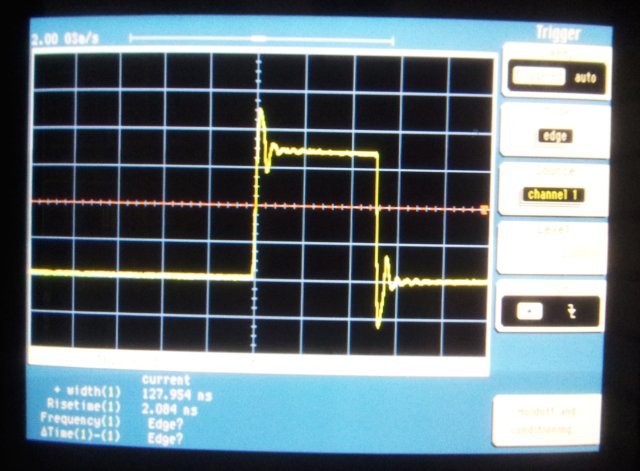

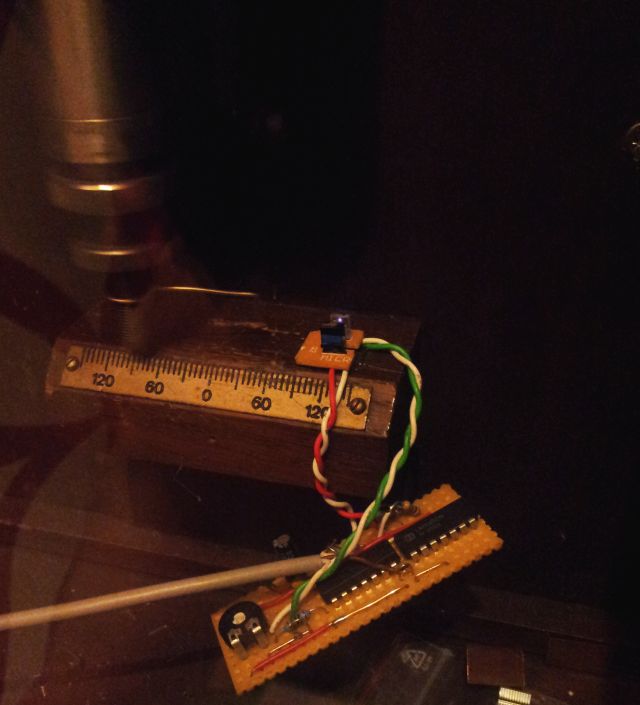

To get the signal out of the clock, a small light gate has been setup inside, and a 1 mm wire connected to the lower end of the pendulum (in a way to ensure virtually no movement of the wire). The wire interrupts the light gate approximate at the lowest point of the pendulum, i.e., when it has its highest speed – this is to ensure sharp edges of the signal.

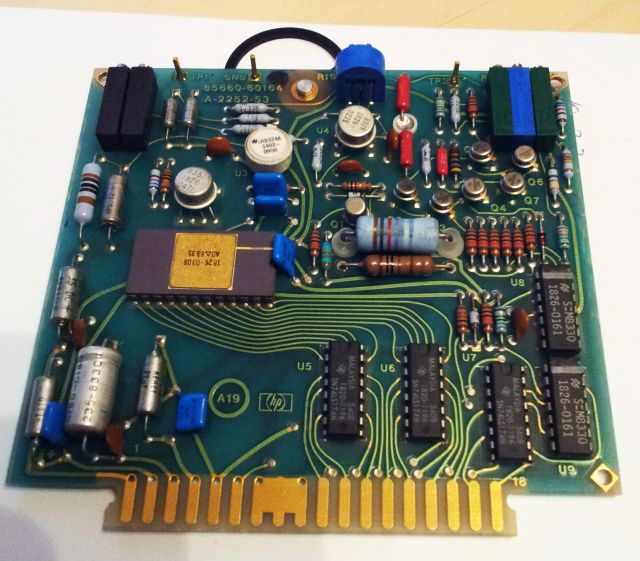

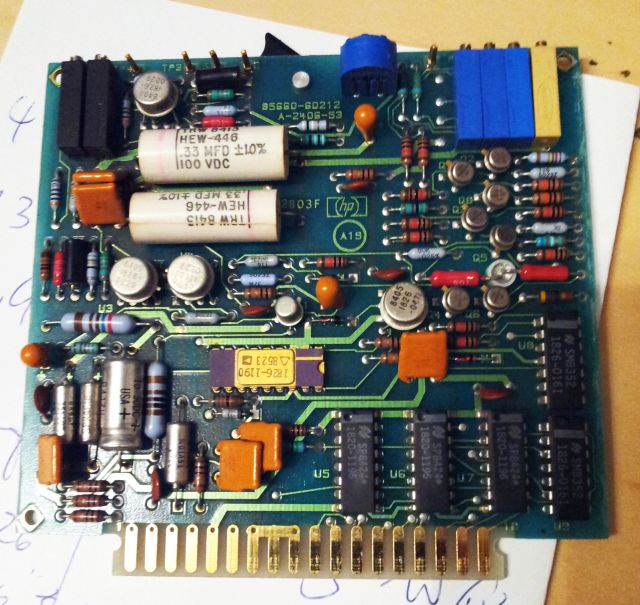

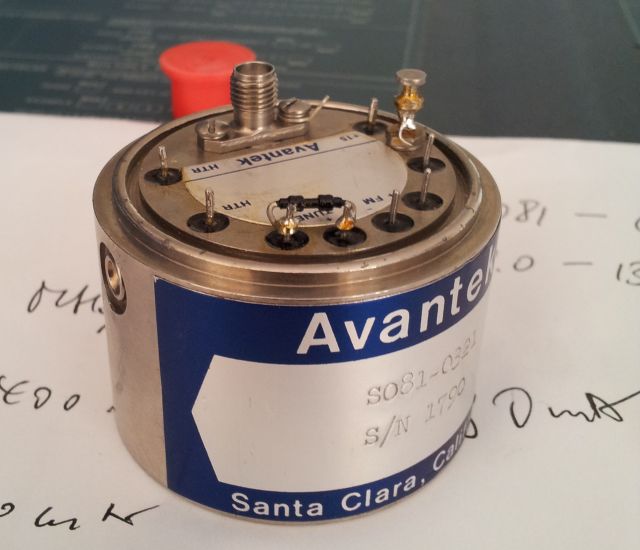

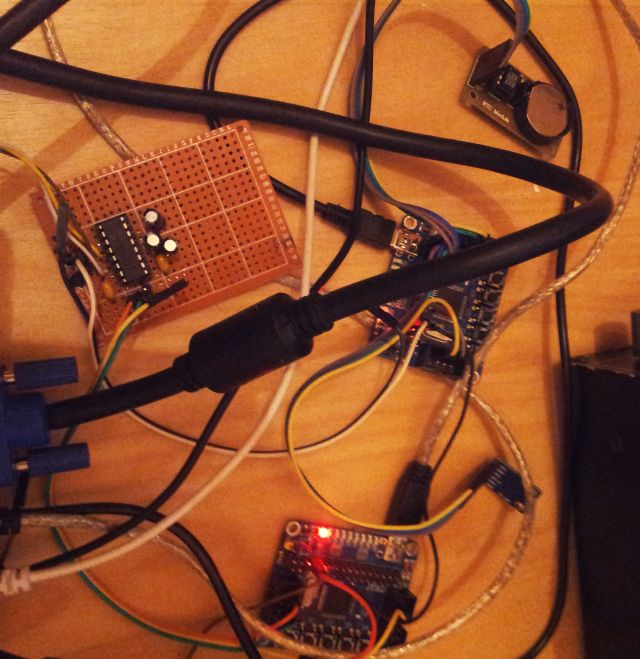

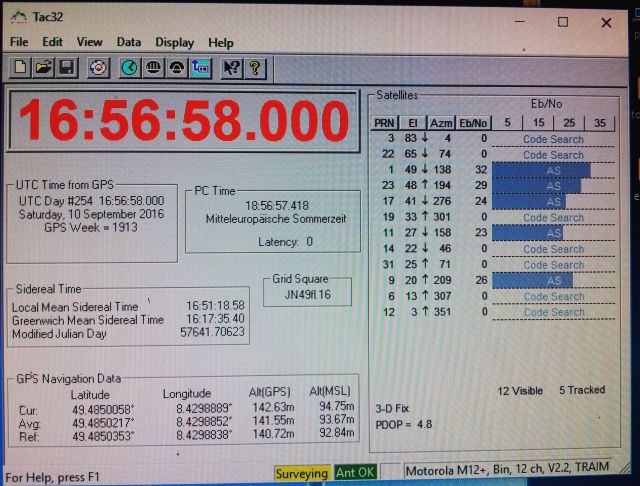

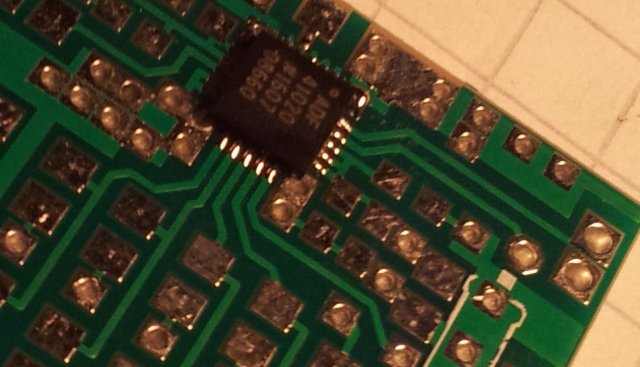

The setup, currently it is just a set of boards running the TIC4 and LOGGER5 software discussed earlier. A Dell OptiPlex FX160 is used to collect the data, but you can use any kind of computer that can handle RS232 input.

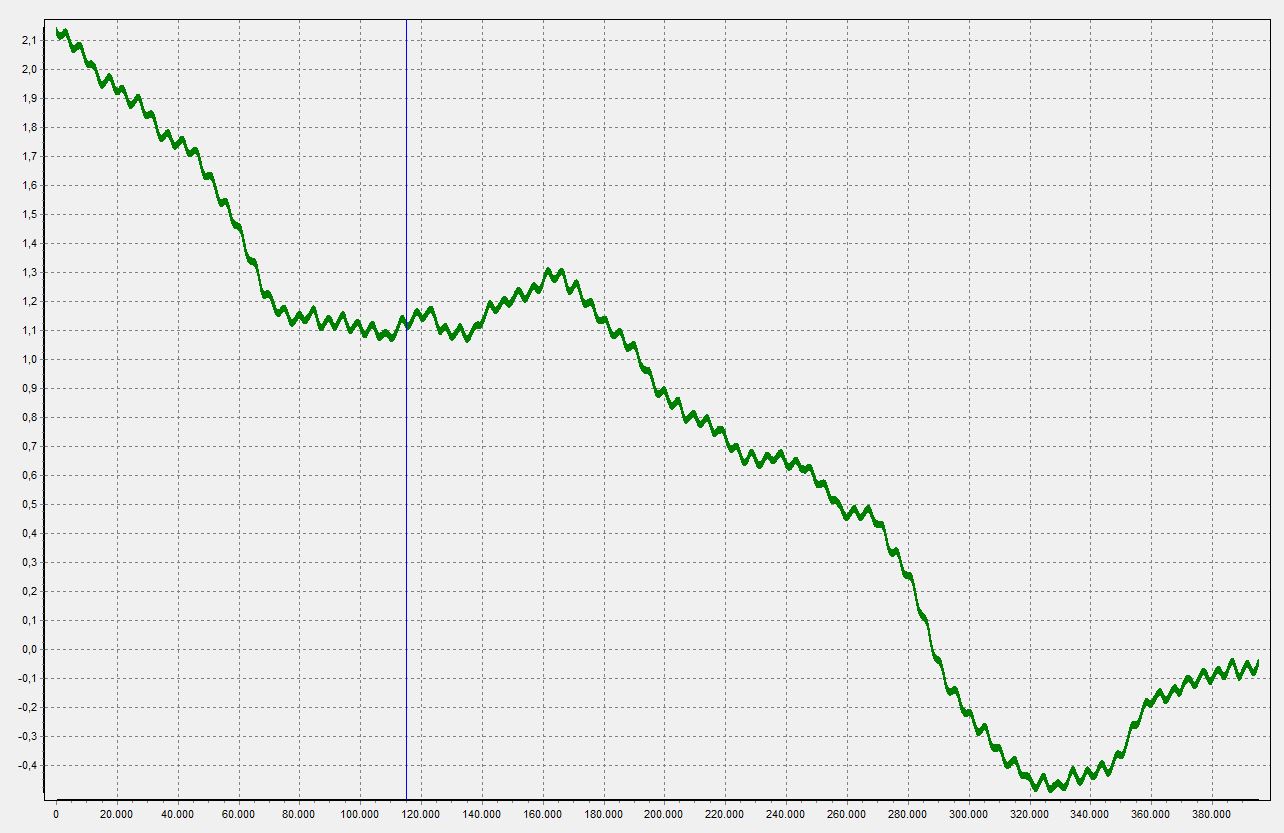

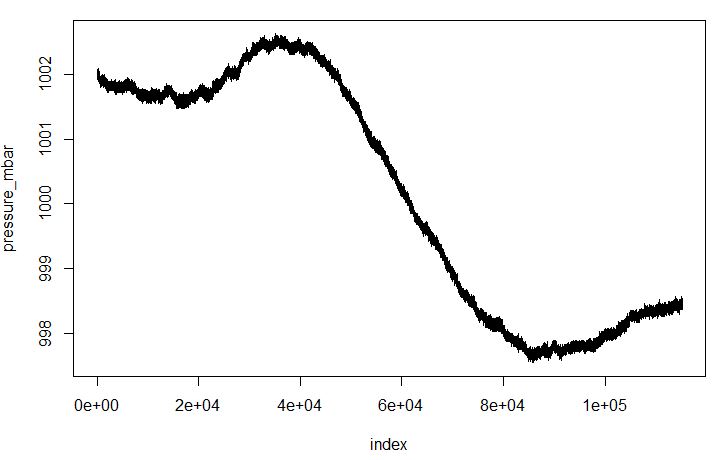

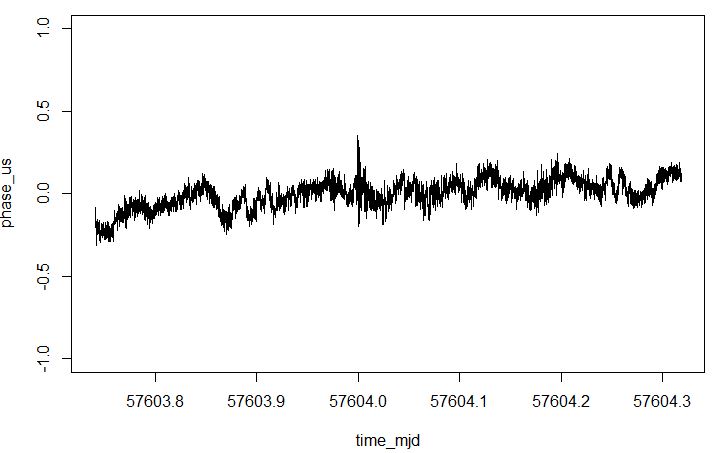

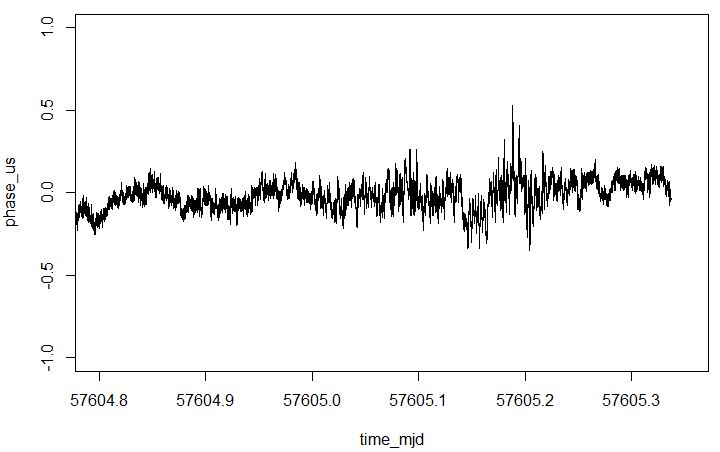

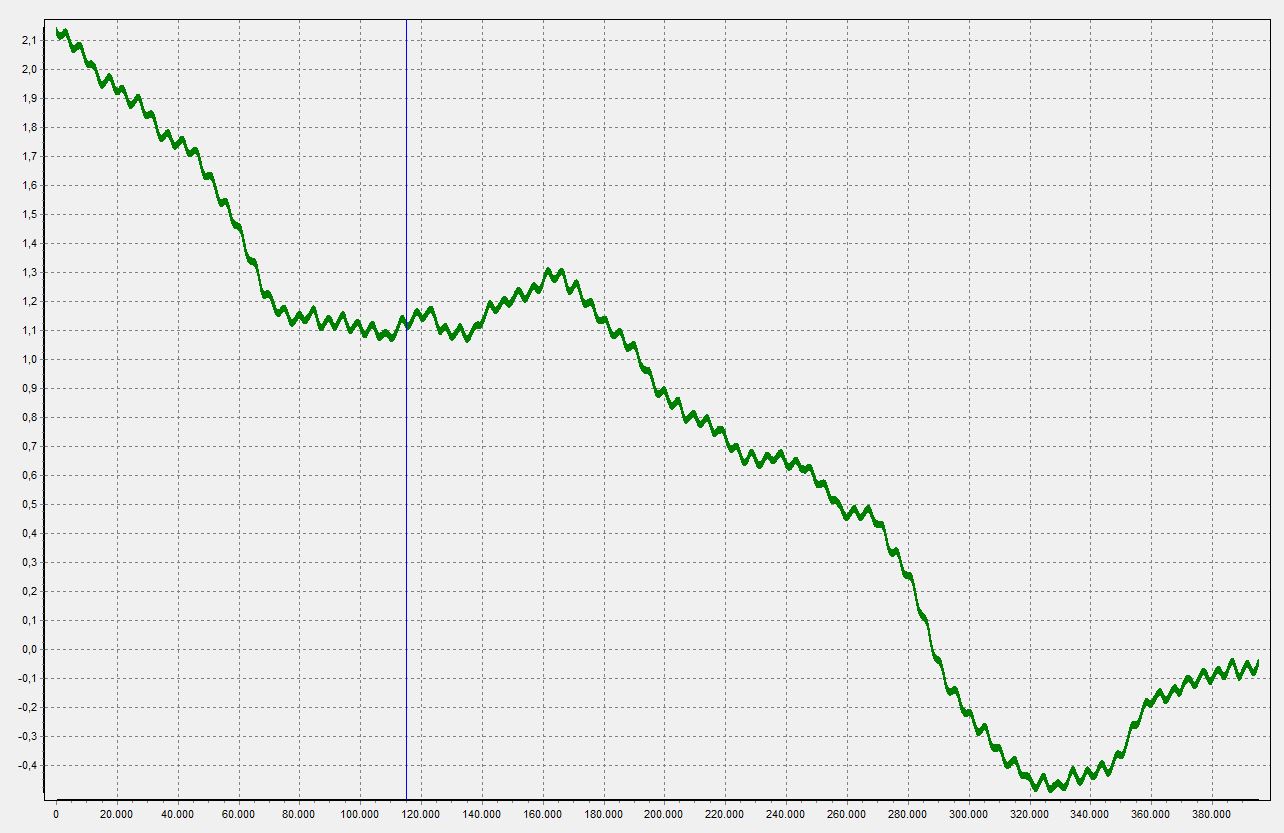

Here, some first results – more to come. Phase is given in seconds, and horizontal axis shows the tick counts – about 115k ticks per day. The software uses narrow time gating to sort out any incorrect ticks, caused by electrical interference, or other random disturbances. There are no more than 1-2 of such events every day. The phase reconstruction algorithm also handles any missing ticks, and the measurement accuracy is not compromised if one or more tick events are not registered for any random reason.

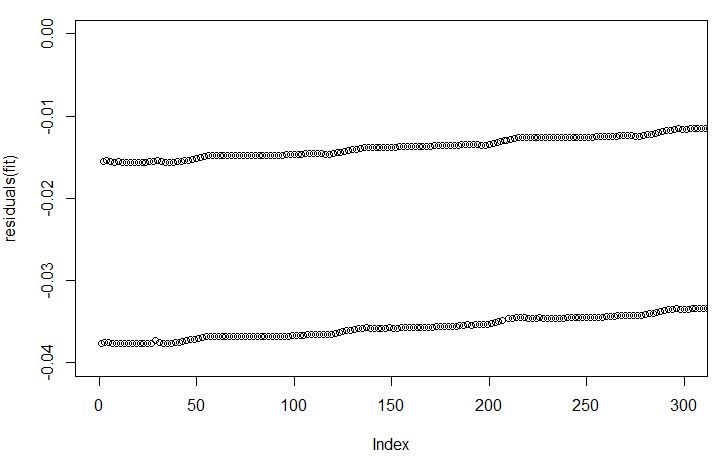

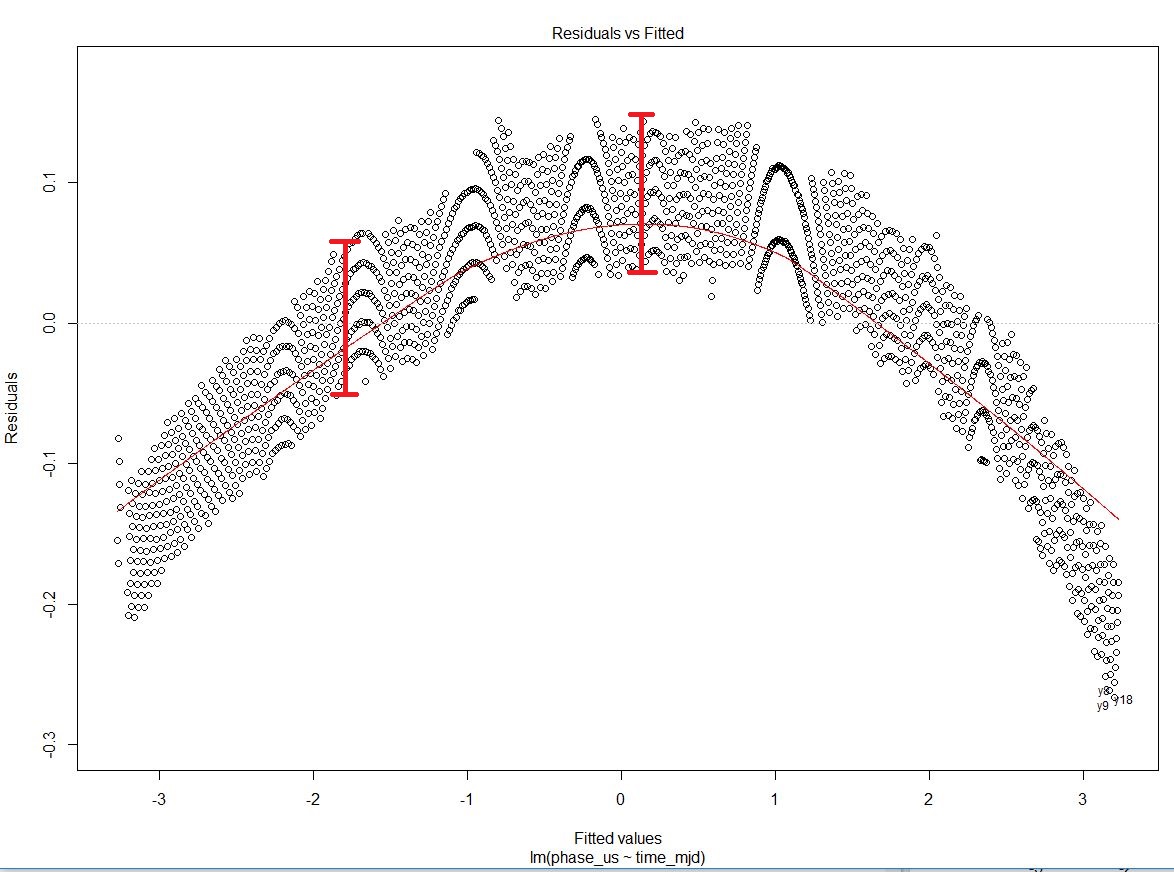

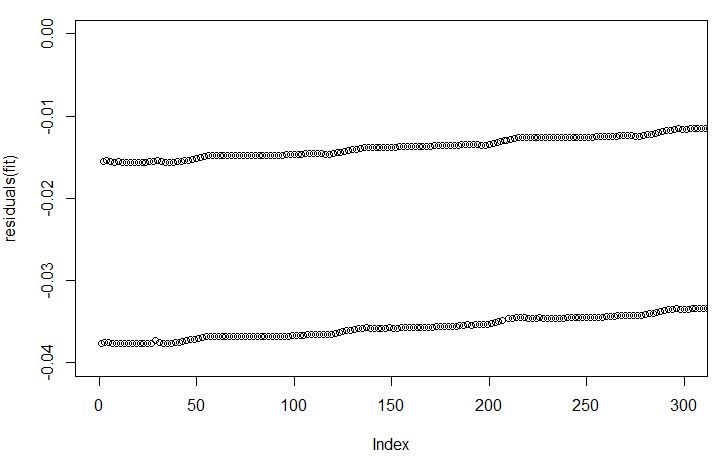

Removing the linear part – not a lot of residual phase error left. Plus minus a fraction of a second a day. Now I have slightly slowed down the clock by removing a tuning weight from the pendulum.

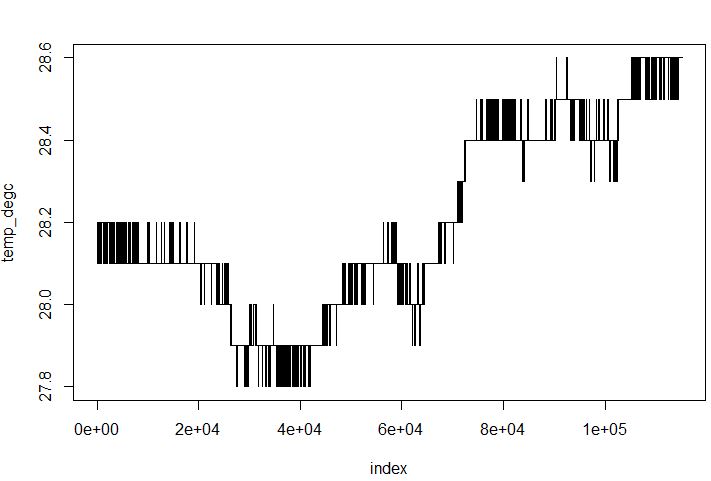

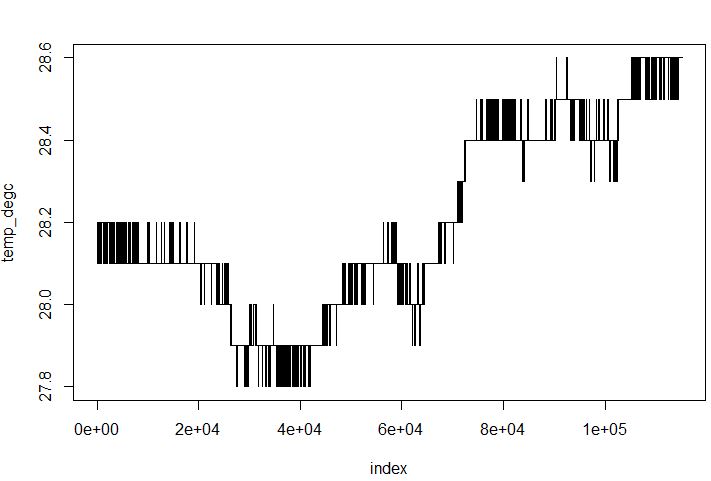

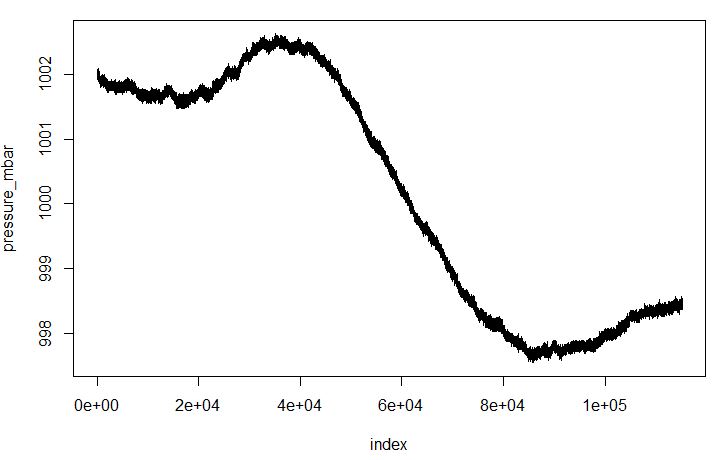

As described earlier, the LOGGER5 setup also records real-time (not to a high degree of precision, just to keep track of time and day), and temperature/pressure. See earler post, LOGGER5, and TIC4.

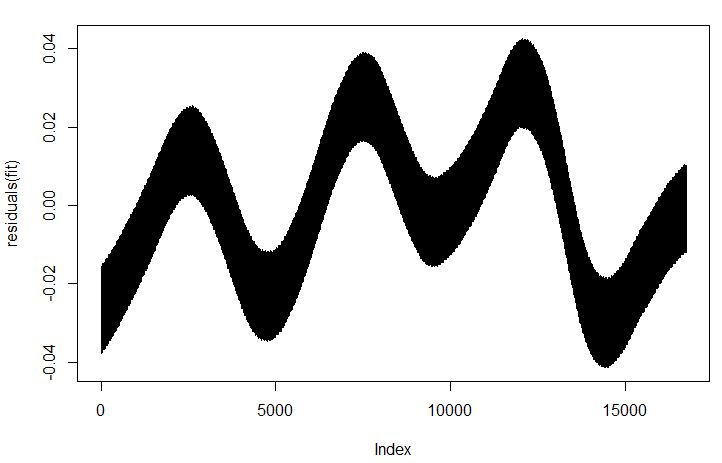

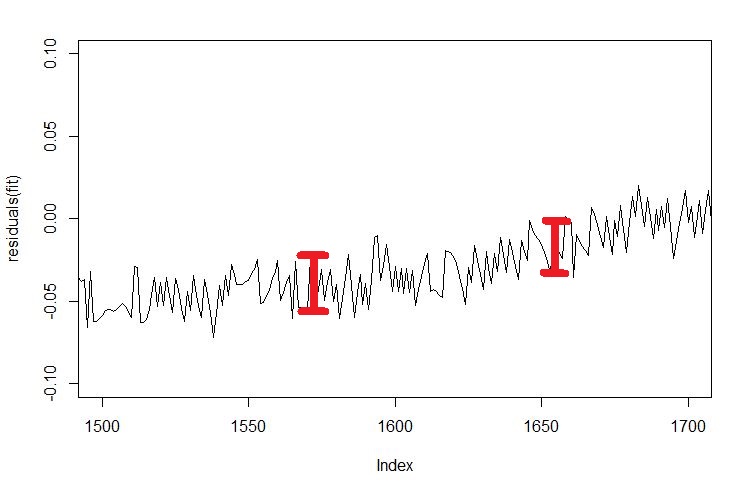

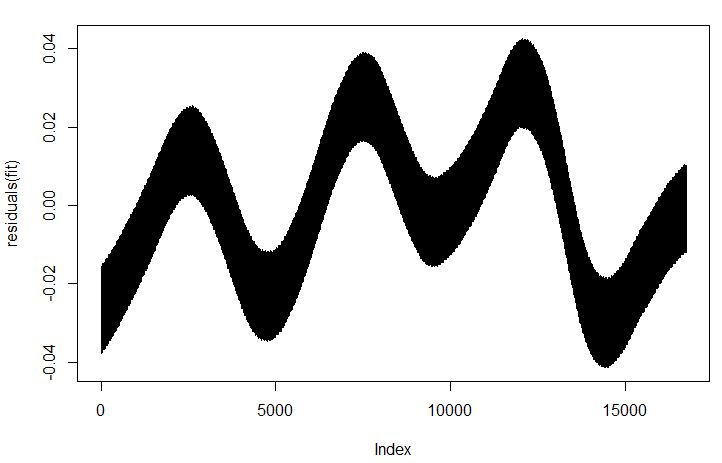

Below, and interesting feature of the data – with the re-loading of the clock every minute, there is some slight variation of the frequency. It is really not much considerable the notable “CLICK” with every re-wind, done by a large magnetic coil, actuating a lever mechanism.

The hourly variation, most likely, related to the travel of the minute hand – will check this later, simply by removing the hands!

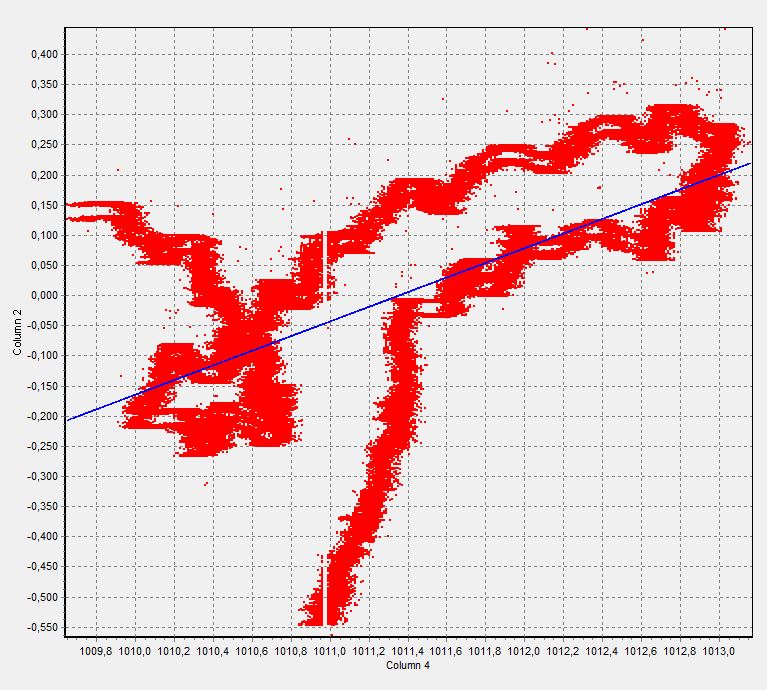

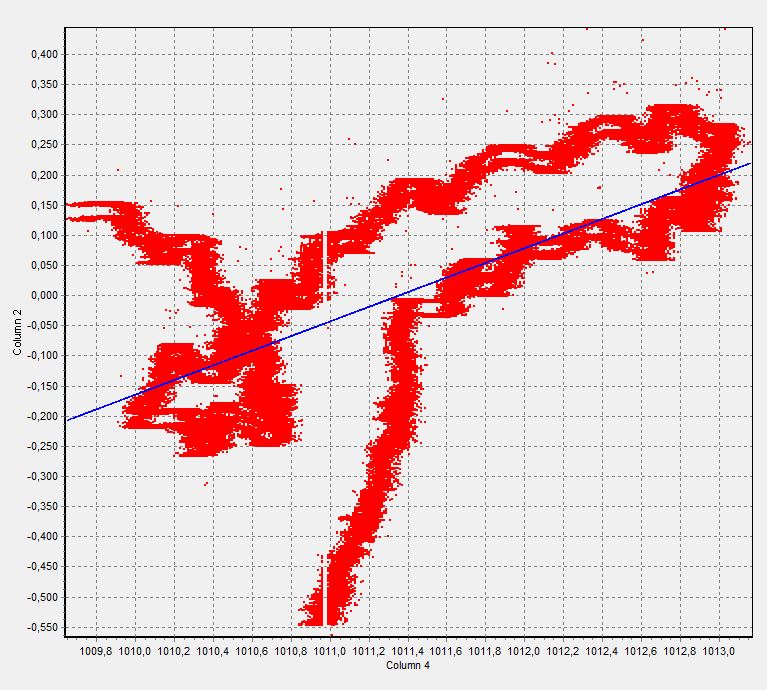

Some first correlation of frequency vs. pressure, but will need to collect much more data, and then correlate with pressure and temperature.

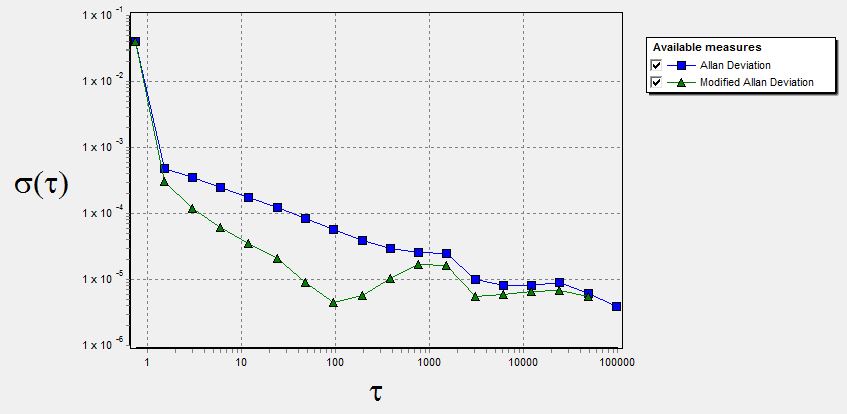

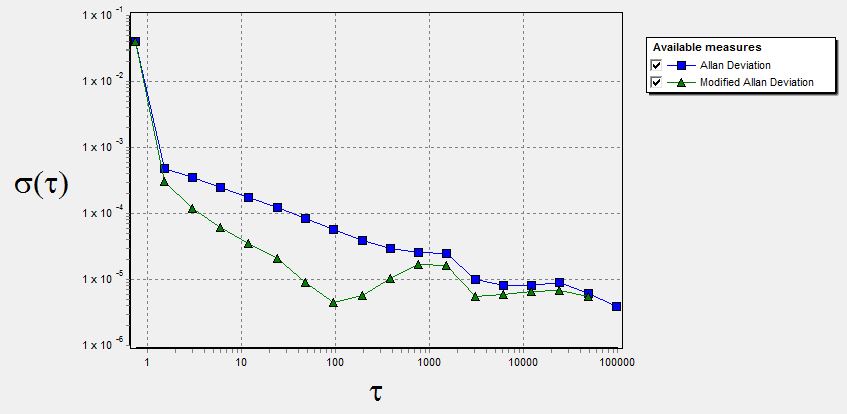

Finally, the Allan variation of the clock, determined from a few days worth of data. Short term stability is compromised by the bi-directional pick-up of the pendulum (detection is at the rising edge of the pulse, which corresponds to two different positions of the pendulum relative to the light gate – because of the discrete thickness of the wire).