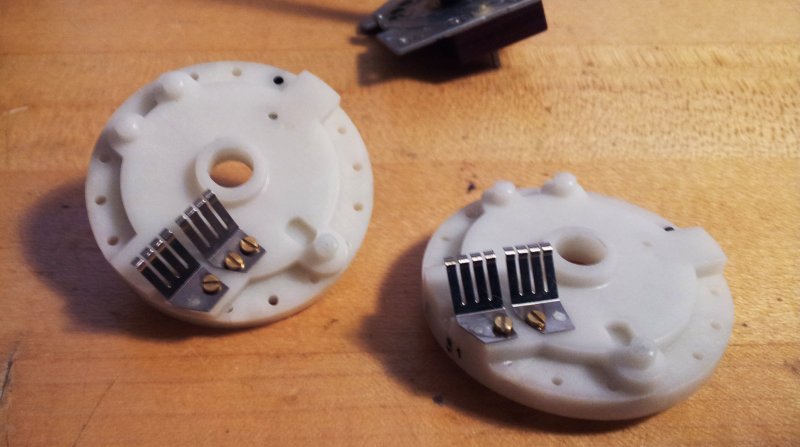

Another 8569B repair, dealing with the aging plastic of the front panel assy rotary switches. Having the variable ref level encoder fixed earlier (ref level encoder repair), the level rotary switches were fixed, by using some small (metric) M1.2×0.25 brass screws.

Most important – the holes to be tapped for the screws need to be drilled quite accurately, using a 0.8 mm drill. This is best done on a milling machine or precise drill press, or with a very steady hand. If you don’t have a drill press, make sure all is as straight and perpendicular as possible.

A M1.2×0.25 tap is then used to thread the parts, make sure to start the tap perpendicular to the surface (a single tap, or machine tap will be fine – no need to use tap sets).

M1.2 screws will fit pretty snug through the contacts, so you might need to use a small screwdriver or similar tool to slightly enlarge the holes of the contacts.

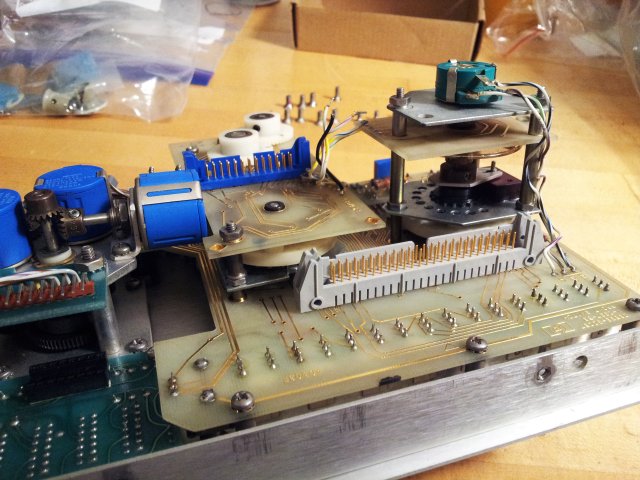

Final stage of assembly, still with some of the wires unsoldered…

Excellent job!

I had the same problem couple of years ago and sorted it in the same way (with small screws from broken reading glasses).

I have missing flexible spring fingers on the FREQ SPAN/Div switch of my hp 8558b Analyzer.

Do you know where I can get usable replacement finger stock for this rotary switch?

Hi, I would suggest to use a piece of thin stainless spring steel, salvaged from some old printer, or other device. It is important that the surfaces are polished, otherwise, the contact will damage the board. Also make sure to remove all the panels of the analyzer, including the side panels, and to turn it upside down and with some force and knocking applied, in most cases, the contacts are still somewhere in the case, at least I found some contacts this way.

Simon

Hi Simon,

I have the same problem with the contacts.. but the real issue is the metal contacts are not there!.. do you know where I can find them ? I need two pcs..

Thank you

kind regards.

Sometimes I found them between the panels and boards so maybe a good idea to remove all panels and have a look. And shake and knock the unit. You can try to make new contacts from sheet metal but hard to do without a spark erosion machine or similar special tool. In August I will be in Germany and can check if I have any spares left. One of the wheels sometimes has two contacts but only one is needed eletrically so you may be able to get at least one by transplantation.