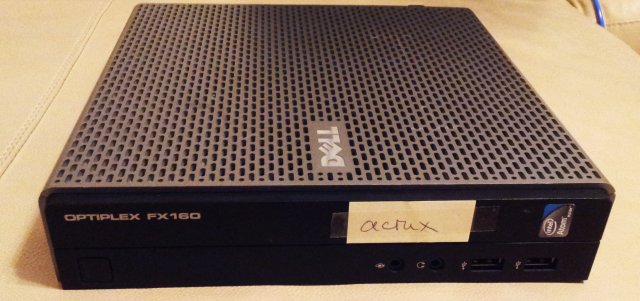

A heavy guest on my bench, a 8663A signal generator. These generators are exceptionally clean, perfect for close-in noise measurement and receiver checks. Still today, hard to find a cleaner source, especially not, if you are on a less than USD 30k budget.

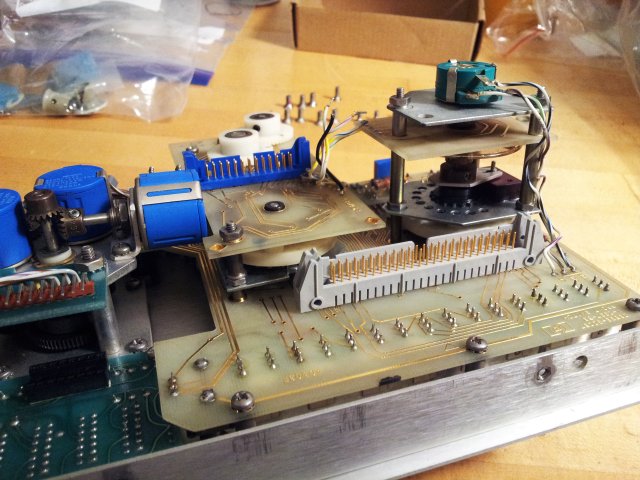

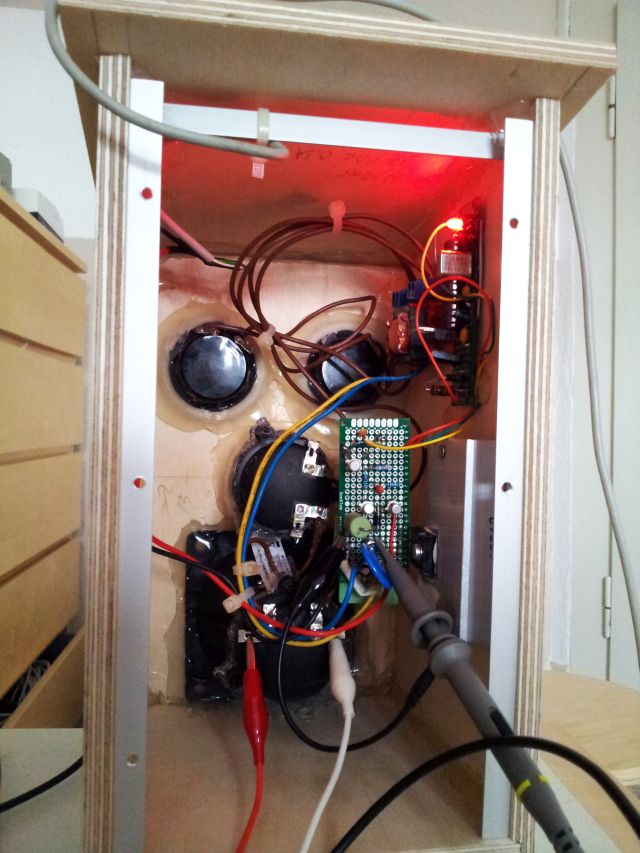

Symptom – easy to describe. Unit turns on, but only briefly, then switches off; over voltage protection light activated at times; a lot of noise on the DC rails when shorting out the safety circuits.

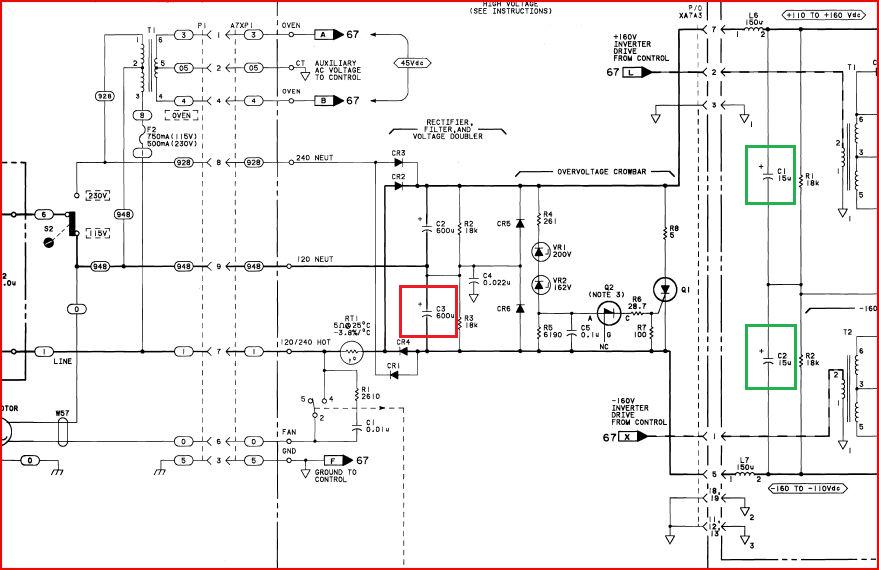

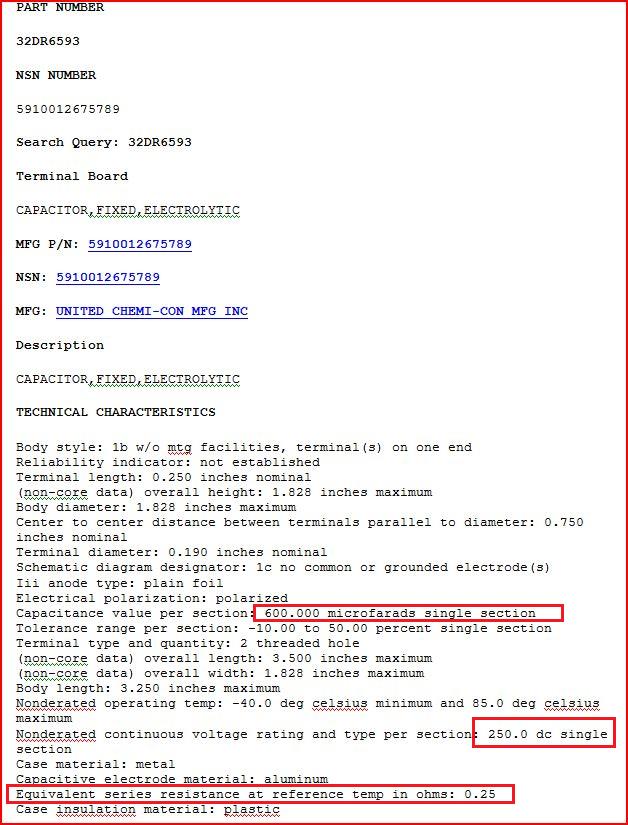

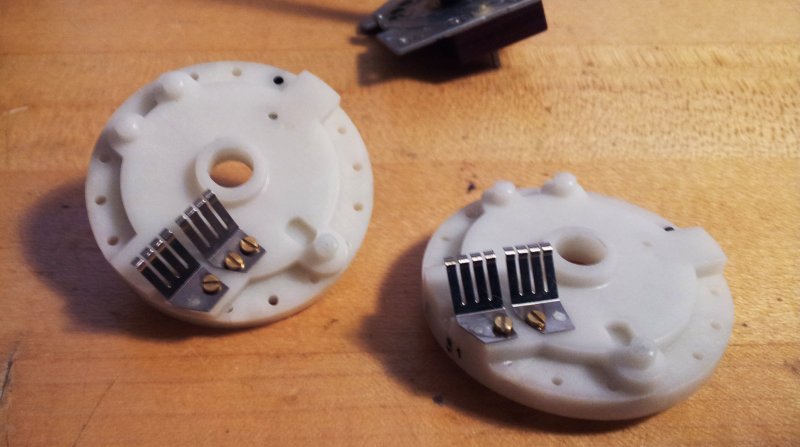

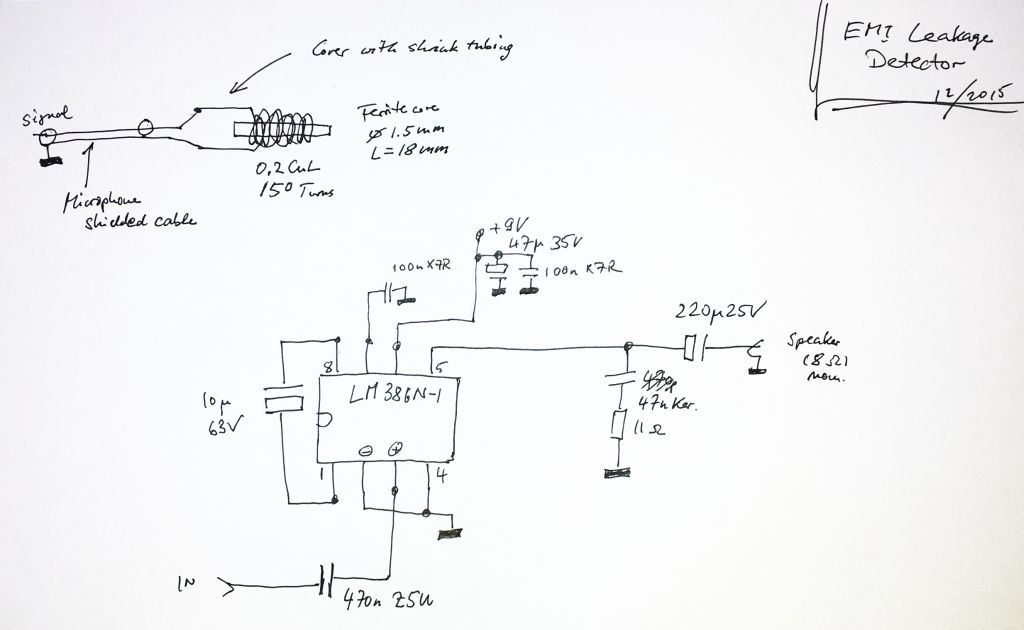

After some probing, the culprit could be located: one of the input capacitors. While this is a common failure mode of other equipment, these caps don’t fail too often for such HP equipment, because only best-in-class components were used, and these are typically run cool, for long life. Still, one of these 32DR6593 SPRAGUE Compulytic caps failed (resistance about 100 kOhm, virtually no capacitance, rapid self-discharge when charged to 50 V for test, framed red in the schematic below).

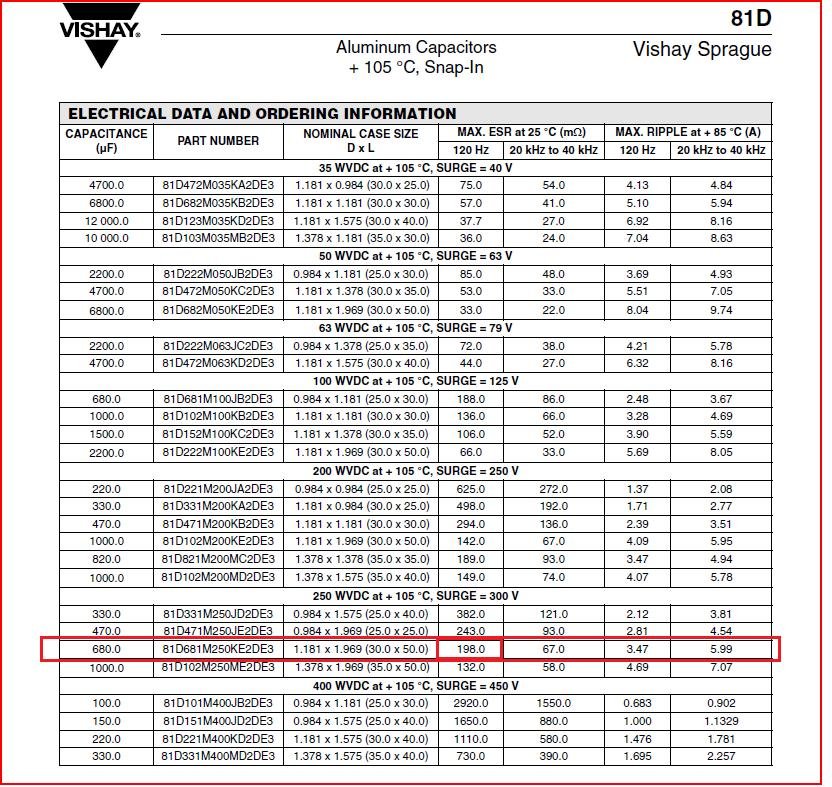

These were replaced by 81D series Nippon Chemi-Con (Vishay) caps. To call this a successful repair, you might wish to check the ESR specifications – the SPRAGUE had about 0.25 Ohms, the Nippon 81D (680 µF, 250 V) has about 0.198 Ohm, good enough. Note that the 600 µF screw-type terminal caps might still be available, but they are pretty expensive, so I opted to for Nippon Chemi-Con, USD 2.50 per piece, surplus, rather than USD 50 for a pair of screw-type caps. I still think it is a good compromise, because this is not about restoring old equipment, but to make this unit working again, quickly, and at lowest cost.

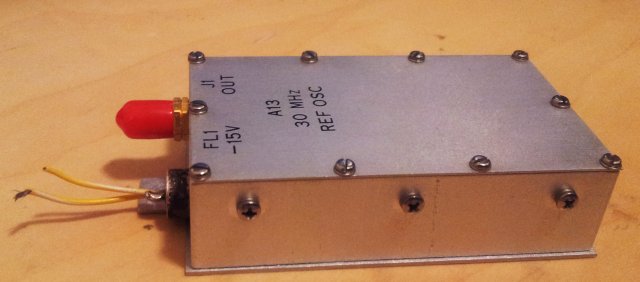

Some repair is also needed on the A7A3 board – there are 22 µF caps that provide a low impedance DC input to the switching transistor, these are essential for operation (framed green in the schematic). They still work, but were hot, and stressed, possibly overstressed, by the dead main cap. Their can be replaced by any good cap, I use Shiangchen GSA T axial caps, 105 deg C rated. Note that the schematic calls for 15 µF, but 22 µF (measuring about 28 µF) were present in the circuit.

With the power supply disassembled, always a good idea to take out the boards for cleaning, and for re-tightening of the screws holding the various TO-3 regulators in place. Some of these were pretty loose (no wonder, with 30+ years of thermal stress on the boards).

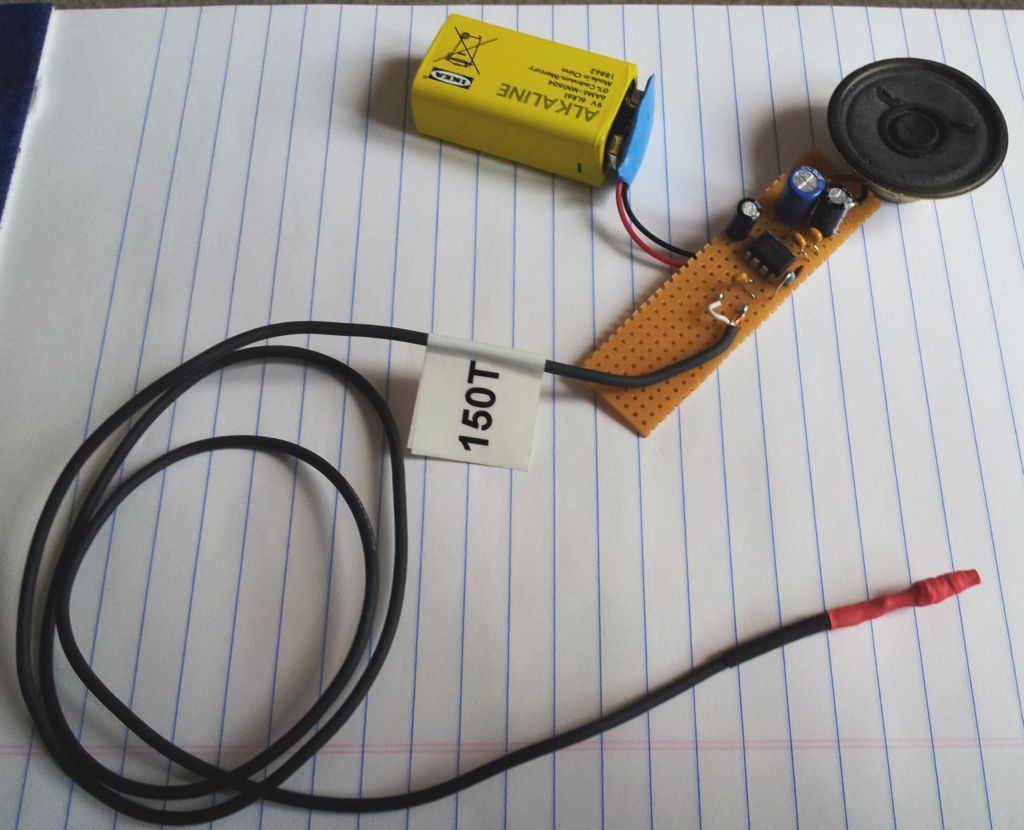

After the repair, add thermal compound to the heatsink/cover – this power supply has a rather critical thermal design. Then, make sure to check the insulation resistance and electrical soundness/earth leakage, which is always a good idea after repair of switchmode power supplies.